The Bryant and Landis line consists of dedicated ID and OD grinders for high precision and production, as well as combination ID/OD grinders for OD, ID, raceway, and face grinding. These grinders are suitable for various applications and are available in different sizes. Our machines are designed to achieve exceptional stiffness, high thermal stability, and accuracy. They feature hydrostatic infeed slides, composite beds, and linear motors. Most importantly, with different machine configurations for slides, grinding spindles, dressing spindles, tools, and fixtures, our grinding experts will find a solution that meets your specific needs.

Inner diameter

Our ID grinders process small parts from 2mm up to 400mm in diameter and can be engineered to suit your production needs. Bryant ID grinders are single spindle machines designed specifically for high capacity and high production.

OUTER DIAMETER

The Bryant RU1 and RU2 machines are high precision OD grinders built for round and out-of-round small parts ranging from 2mm to 350mm. In addition, these machines are ideal for fuel management, valve train, bearings, pumps, and more.

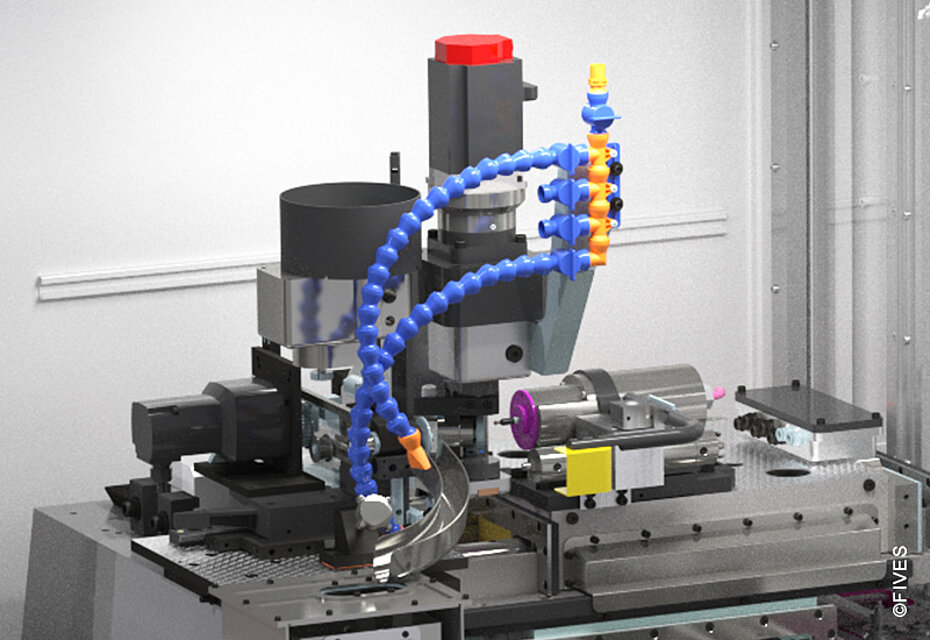

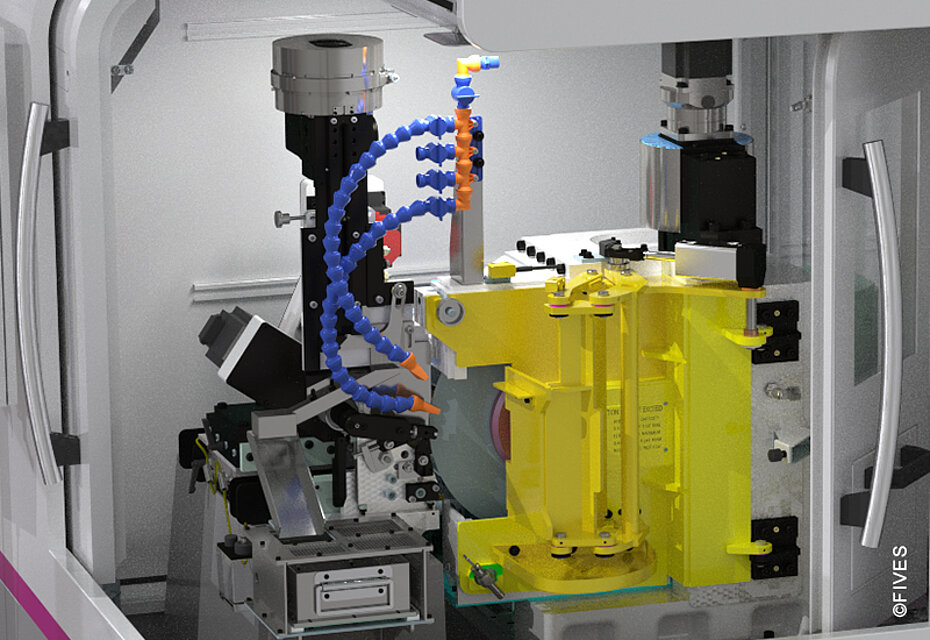

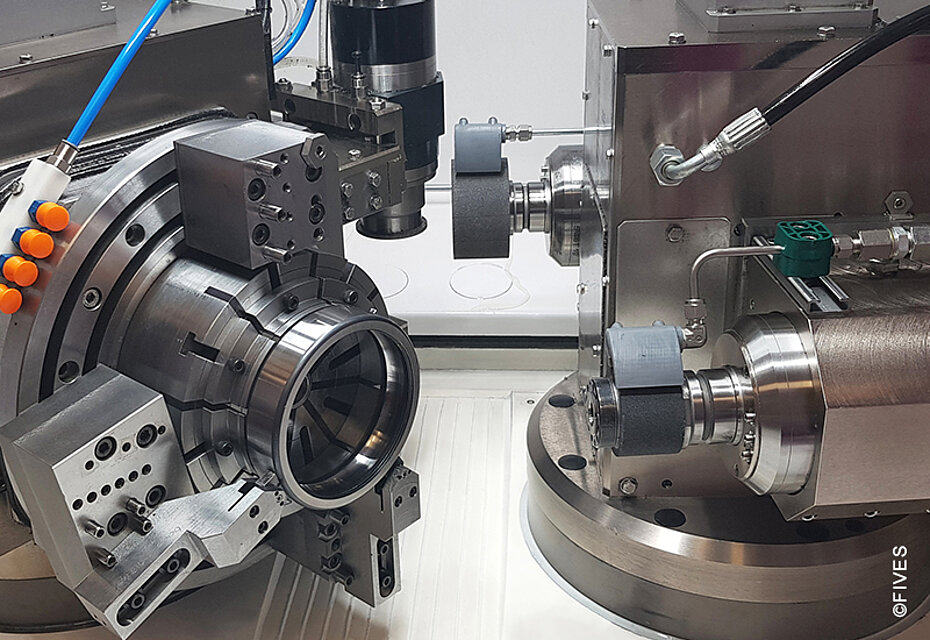

Combined ID/OD grinding

Our combination OD/ID/raceway/face grinders offer high flexibility for workpiece grinding operations with maximum precision and productivity. In addition, these machines provide ultimate thermal stability in a compact machine footprint.