Multiple grinding operations can be carried out with ease thanks to flexible slide configurations, multiple spindles, and a range of wheel heads and dressing systems.

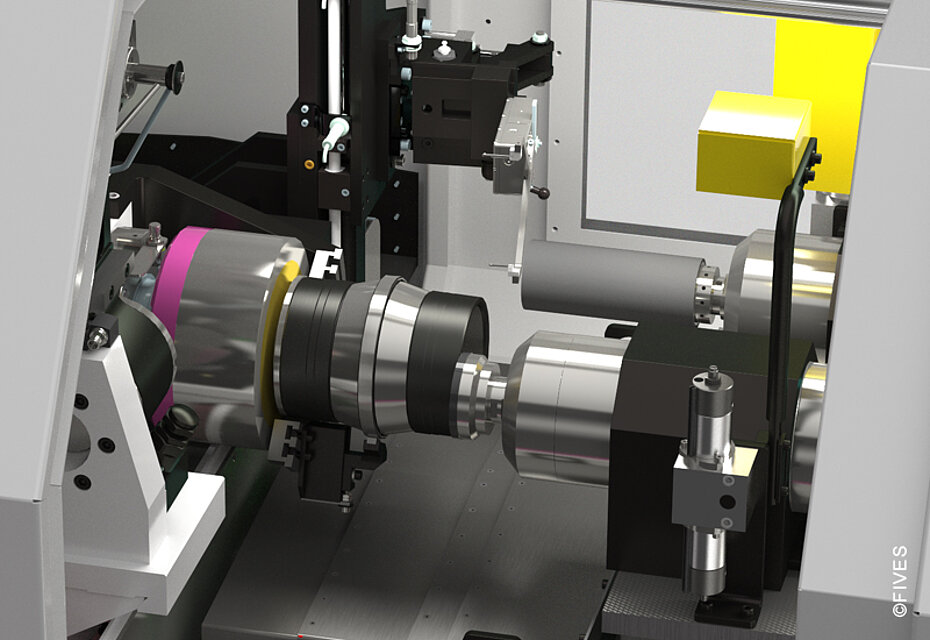

Flexible and compact: ID/OD grinding with the Bryant RU2

With floorspace at a premium, you need a compact machine that can give you more bang for your buck. Built for ID/OD grinding, the Bryant RU2 is capable of carrying up to four spindles per machine for the ultimate in flexible, precision grinding, of complex components.

Check out our Bryant RU2 flyer to learn more.

Engineered for precision grinding

The Bryant RU2 is engineered for precision grinding. From the composite bed, ensuring excellent thermal stability, to the 0.1 µm glass scales, and linear motors for precision control. In addition, the Bryant RU2 promises no backlash, minimal maintenance, and maximum runtime. Making the machine ideal for:

- Bearings

- Valvetrain

- Turbochargers

- Fuel systems

- Aerospace and medical applications

- Custom engineered solutions

ID/OD grinding you can rely on

As with all Bryant machines, the RU2 promises:

- Optimum dimensional and geometric accuracy

- Excellent thermal stability

- A small, compact footprint

- Linear motors for precision control – no backlash

- Fully automated system

- Extremely high production

- Reduced number of wear parts

- Very low maintenance

The result? Optimized productivity, minimum scrap and a consistently high-quality finish you can be proud of.

Large operational capability in a compact footprint

The Bryant RU2 is ideal for OD/ID, face, and form grinding applications. The machine further benefits from a dual-slide arrangement and spindle speeds up to 120,000 rpm, giving you optimum productivity.

specifications

|

| ||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||