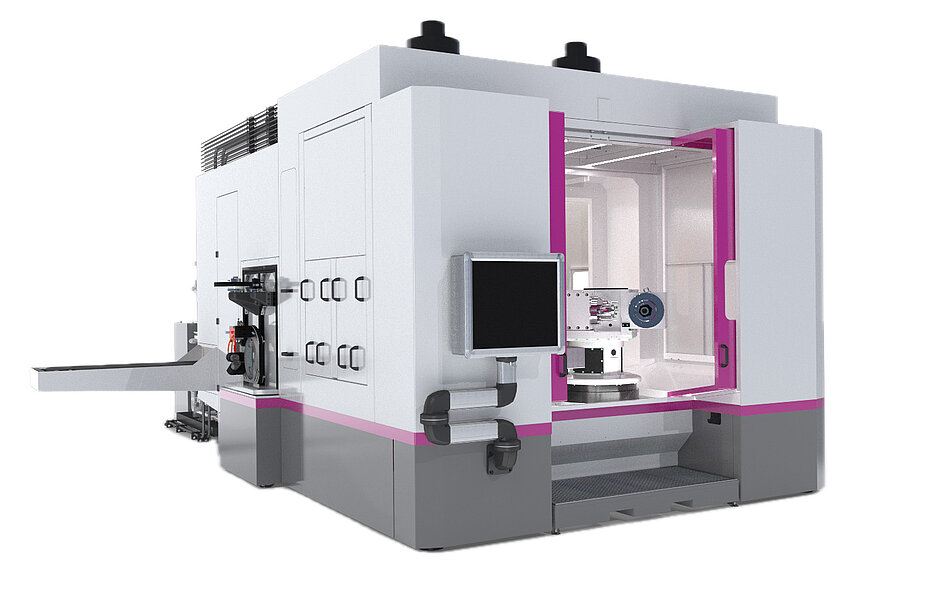

Speed up your manufacturing process and cut operating expenses with the Landis TTG 3000. This twin-turret, multi-spindle solution consolidates multiple operations within a small space, allowing you to optimize your production capabilities. Achieve precision grinding of ODs, IDs, faces, tapers, raceways, concentric, and eccentric diameters to sub-micron tolerances, all in a single clamping.

complete flexible grinding with the Landis TTG 3000

Unlock unprecedented control over your production runs with the versatile Landis TTG 3000. Whether you're managing small batches, high-volume orders, or diverse products in a single run, this machine maximizes efficiency and quality. Minimize downtime during component changeovers and consistently achieve superior results with its cutting-edge automation.

Furthermore, the Landis TTG 3000 can be tailored to fit your unique manufacturing and layout needs. Like all Landis machines, it boasts exceptional stiffness and high thermal stability, courtesy of the thermally isolated hydrostatic twin turrets. Trust in the reliability and precision that only Landis can deliver.

Check out our Landis TTG 3000 flyer to learn more.

_4b46be3b11.png)

MACHINE HIGHLIGHTS

The Landis TTG 3000 delivers exceptional features including:

- High flexibility in workpiece grinding operations

- Versatile spindle configurations

- Capabilities for hard turning and polishing

- Reduced workpiece changeover time

- Maintained constant wheel surface speed

- Exceptional surface finishes

- Seamless integration with automation

- High-performance control with open architecture

_d38fd48991.jpg)

OPEN ARCHITECTURE CONTROL

Effortlessly integrate the Landis TTG 3000 into your existing automation system. Designed with open architecture control, this advanced machinery offers exceptional benefits. Enjoy advanced monitoring capabilities, seamless sensor integration, and user-friendly programming—all in a fully-integrated package. Maximize your efficiency and stay ahead with the innovative Landis TTG 3000.

The Ultimate Grinding Solution

Experience unmatched versatility with the Landis TTG 3000, capable of accommodating up to three distinct spindles. This flexibility allows you to efficiently tackle a wide variety of grinding tasks including round and non-round components. The Landis TTG 3000 excels in a variety of operations, including but not limited to ID taper, ID cylindrical, surface, chamfer, radius, and OD cylindrical grinding, all on a single versatile machine.

With the Landis TTG 3000, precision is guaranteed thanks to:

- Extraordinary thermal stability

- Exceptional stiffness

- Small batch runs of diverse product lines

- Combined grinding processes

- Flexible grinding process based on requirements

Landis TTG - Flexible Grinding Solution

The perfect answer to issues faced in the modern manufacturing process, allowing flexible processing, fast changeover, and flexible layouts.

Innovative ID/OD Grinding Solutions

Flexible and innovative grinding solutions for a variety of high-precision ID/OD applications in different industries.

specifications

| Grinding Capacity | |

| Max. grinding diameter (OD) | 350 mm |

| Max. external grinding length | 100 mm |

| Max. internal grinding length | 100 mm |

| Grinding Spindle Turret | |

| Swivel range | +/- 150° |

| Turret bearing | Hydrostatic |

| Turret motor torque | 1050 Nm |

| Max. number of spindles | 3 |

| Wheel type | Conventional / CBN / Diamond |

| Max. wheel Ø | 350 mm |

| Wheel surface speed | 120 m/sec |

| Max. ID spindle speed | 110,000 rpm |

| Workhead Turret | |

| Swivel range | +/- 135° |

| Turret bearing | Hydrostatic |

| Turret motor torque | 1050 Nm |

| Workhead speed | 1 - 1,250 rpm (high speed option available) |

| Linear axis travel (infeed) | 350 mm |

| Linear axis bearing | Hydrostatic |

| Linear axis drive | Linear Motor |

| Dimensions | |

| Machine dimensions (W x D x H) | 3,000 x 2,800 x 3,000 mm |

| Machine weight | 10,000 kg |

| Grinding Capacity | |

| Max. grinding diameter (OD) | 13.8” |

| Max. external grinding length | 3.9” |

| Max. internal grinding length | 3.9” |

| Grinding Spindle Turret | |

| Swivel range | +/- 150° |

| Turret bearing | Hydrostatic |

| Turret motor torque | 1050 Nm |

| Max. number of spindles | 3 |

| Wheel type | Conventional / CBN / Diamond |

| Max. wheel Ø | 9.8” |

| Wheel surface speed | 120 m/sec |

| Max. ID spindle speed | 110,000 rpm |

| Workhead Turret | |

| Swivel range | +/- 135° |

| Turret bearing | Hydrostatic |

| Turret motor torque | 1050 Nm |

| Workhead speed | 1 - 1,250 rpm (high speed option available) |

| Linear axis travel (infeed) | 13.8” |

| Linear axis bearing | Hydrostatic |

| Linear axis drive | Linear Motor |

| Dimensions | |

| Machine dimensions (W x D x H) | 9.8’ x 9.2’ x 9.8’ |

| Machine weight | 22,026 lb |