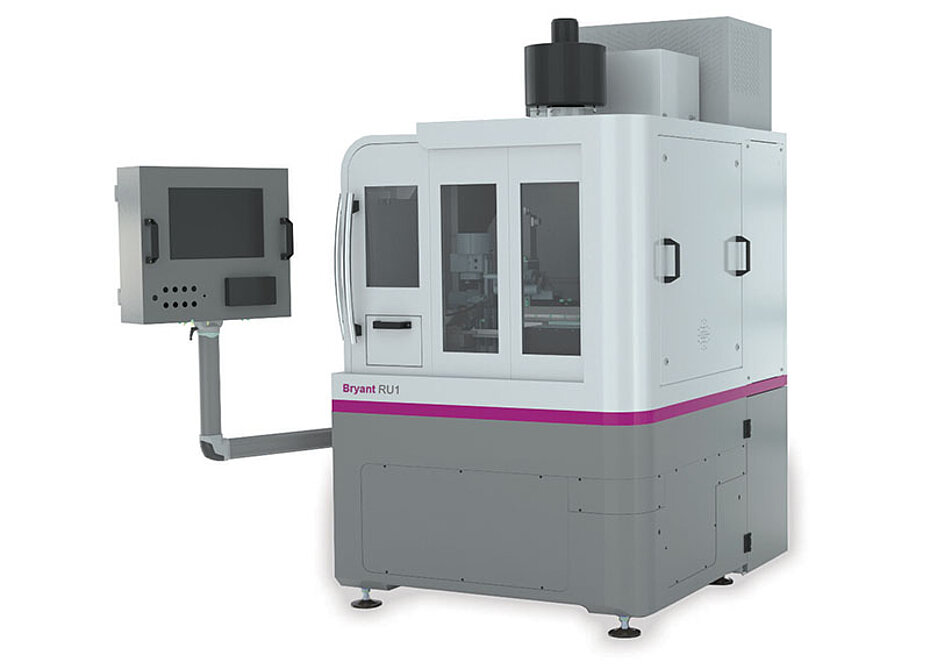

The Bryant RU1 is the ideal inner diameter precision grinding solution for all small parts under 50 mm. This includes bearings, thin shafts, valve train components, pumps and other small components.

precision inner diameter grinding for small parts

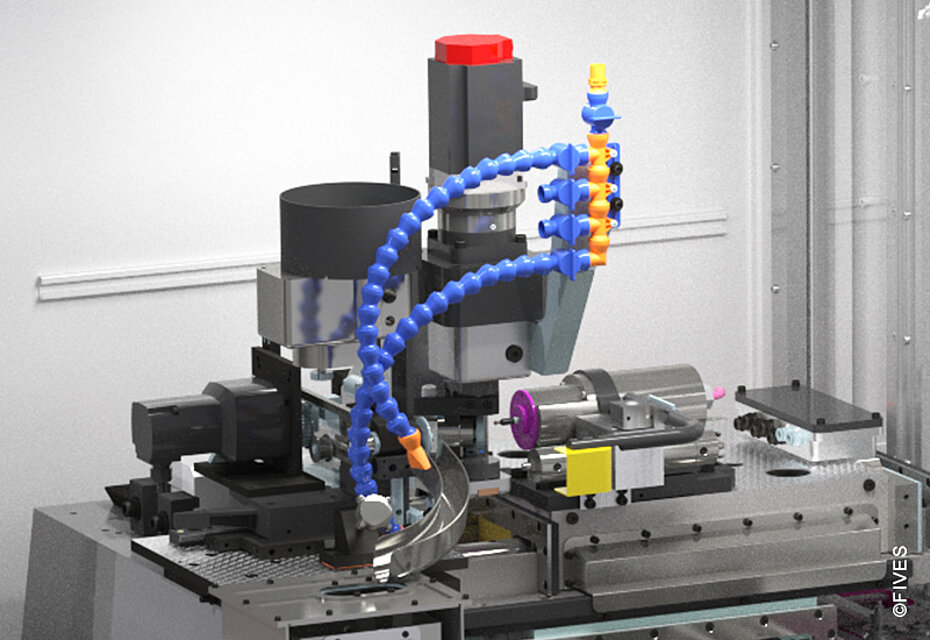

As a modular system, the Bryant RU1 can be engineered to fit your manufacturing process. For instance, from spindle position, to wheel size, tools and fixtures; this machine gives you the flexibility you need for maximum efficiency. Spindle options range from 5,000 – 110,000 rpm, with wheels options 1mm in size.

Check out our Bryant RU1 flyer to learn more.

machine highlights

Additional machine features include:

- Ultimate dimensional and geometric accuracy

- Linear motors for precision control – no more backlash

- A small, compact footprint

- Extremely high production

- Very low maintenance

- Excellent thermal stability, thanks to the composite bed and thermal compensation system

- Fully automated system, requiring minimal human intervention – removing the possibility for human error

Ultimate precision grinding

With exceptional stiffness and high thermal stability of the hydrostatic round-bar infeed, the Bryant RU1 delivers ultimate precision grinding in a compact footprint.

There is a targeted focus on performance in all elements of this machine. From the linear motors to the modular design of the Bryant RU1, you always get the high-quality finish you need in the best arrangement for your process.

specifications

|

| ||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||