Small Parcel Distribution

Postal and courier companies are struggling to cope with exploding online sales. Fulfilment centers are handling more small parcels than ever, including carton boxes, cardboard envelopes and plastic bags. Fives’ turnkey small parcel solutions optimize flows and boost productivity, equipping our clients to provide fast, accurate delivery at competitive prices.

Offloading

Small parcels and flyers enter the sorting facility in bags, roll cages, pallets and Gaylord boxes. They are either manually unloaded onto the conveyor system or automatically unloaded by tippers.

Debagging and manual loading

At the debagging positions, operators open bags containing small parcels and flyers and discharge them onto the infeeding line. The items are sent either to a fully automatic infeed area, or a manual loading area where operators load them onto induction line conveyors.

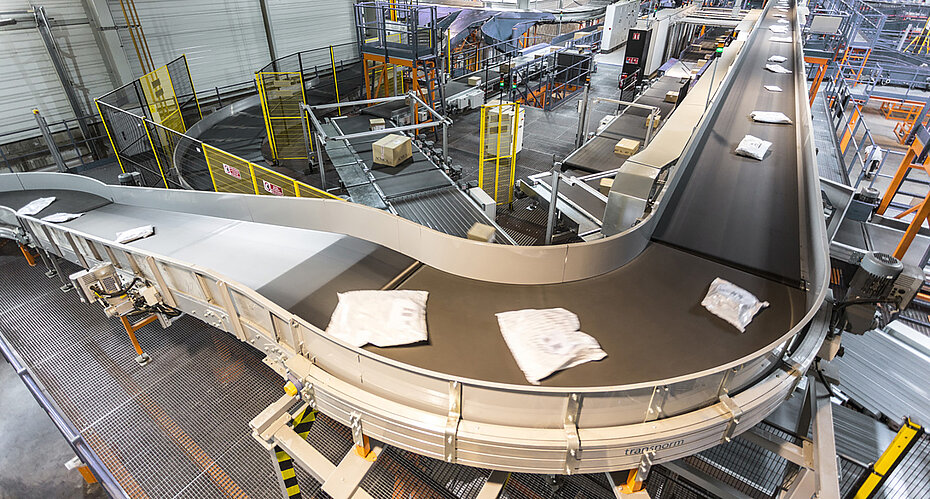

Conveyor system

Comprised of roller and belt sections, the Fives’ conveyor system transports small parcel flow from one processing stage to the next. Our system connects operation zones to reduce the need for manual handling.

Automated singulation process

Automated tippers unload a 3D bulk flow of small parcels into the singulation conveyor. They exit in a single line of properly aligned and spaced items. Singulation occurs automatically without any human intervention.

Specially designed for small parcels, large envelopes and flyers, Fives’ singulators are comprised of inclined unstacking belts and conveyor sections that separate and remove side-by-side items. Parcels are centered, metered and aligned before feeding the downstream conveyor sorting system.

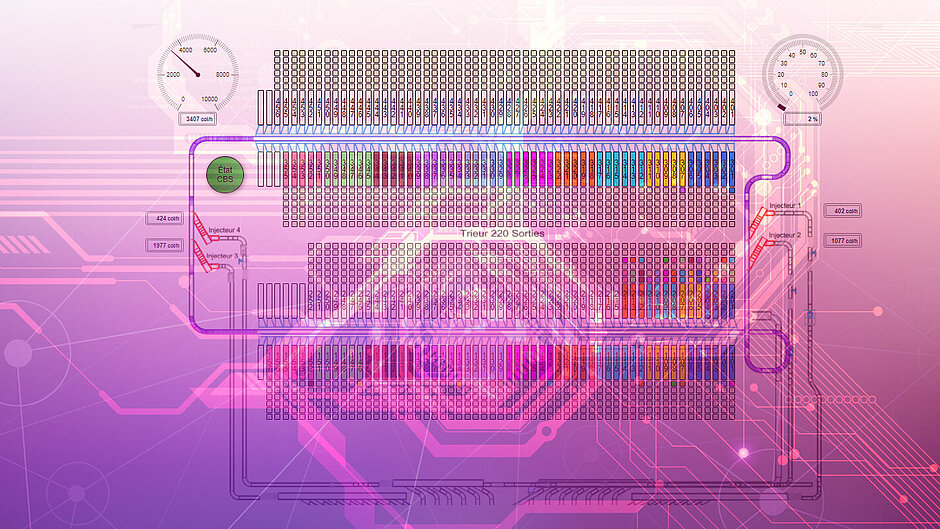

Automated sorting

Our automated sortation system’s induction lines receive small parcels from the singulator or manual loading positions. They transfer these items onto a loop cross belt sorter at zero relative velocity and with incredible accuracy.

Our cross-belt sorter is equipped with special chutes that precisely discharge items into bags, boxes and roll cages. The cross belt ensures gentle handling and constant control of onboard items. Data capture devices scan labels and measure each item’s weight and volume during transportation.

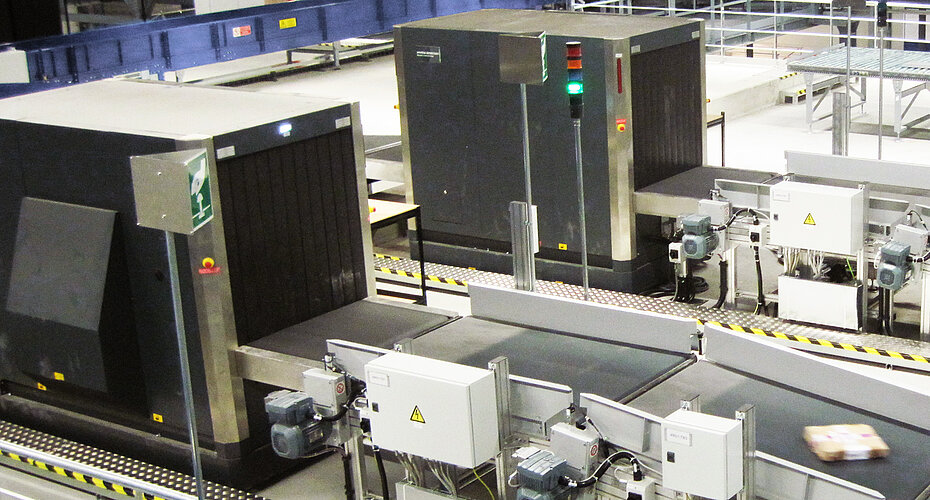

Security check

A special area is designated for security screenings. Small parcels are transported via conveyor through automated or manual x-ray machines and/or explosive detection systems (EDS) for screening.

Manual reworking

Material flow may be deviated to the manual reworking area for various reasons. At this station, operators scan barcodes by hand and perform required operations before reloading parcels onto the conveyor for transport.

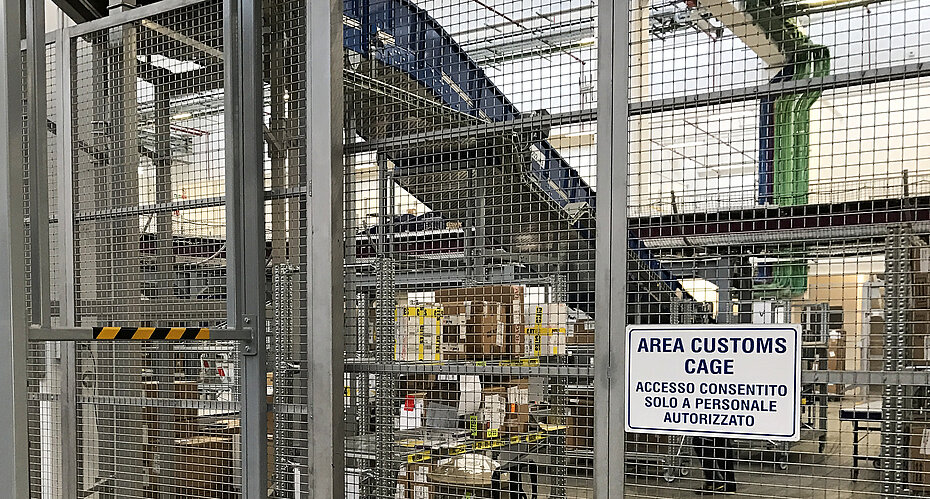

Customs clearance

Dedicated conveyors transport small parcel flow to the customs bond area, where the customs clearance process takes place.

Vehicle reloading

When small parcels heading to the same destination are sorted, operators remove the full bag, box or roll cage and consolidate it for vehicle reloading.