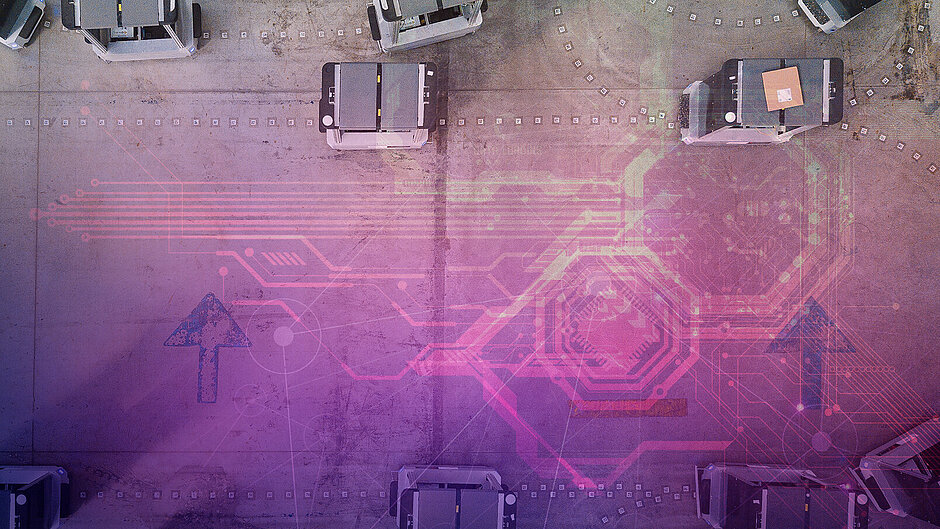

Our GENI-Ant™ Autonomous Mobile Robot Sorter intelligent technology uses an embedded high-performance Traffic Management System to optimize travel paths in real time.

Key features

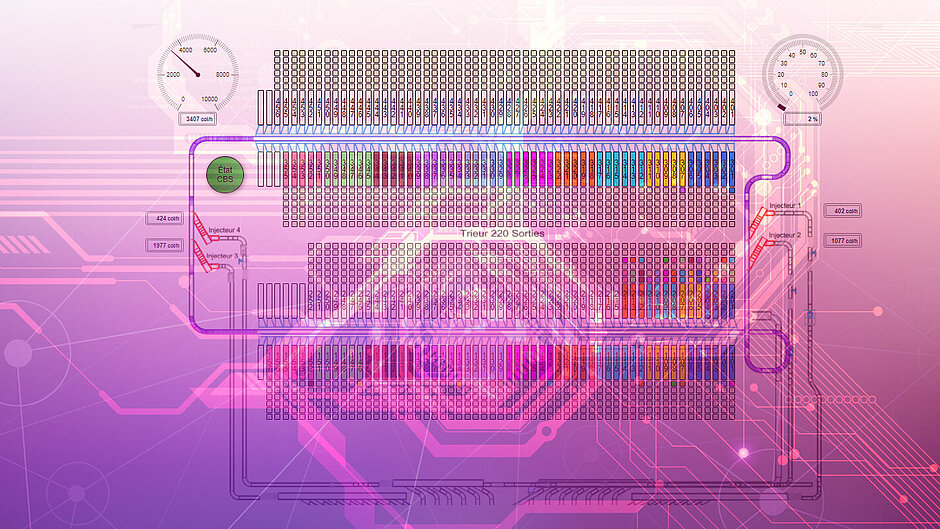

AMR TRAFFIC MANAGEMENT SYSTEM

The GENI-Ant™ AMR Sorter software suite manages and regulates the fleet to streamline operations, reduce downtime and increase operational efficiency of the system.

Each Autonomous Mobile Robot Sorter (AMR) includes software which controls the robot in real time and moves it in an efficient manner within the dedicated area.

The AMR fleet is controlled by a centralized Traffic Management System that optimizes work assignments and fleet movements, sends transport orders to the AMR sorters and monitors traffic. The AMR Traffic Management System also maximizes battery lifetime by managing the AMR’s battery levels, as well as charging areas and characteristics, such as current.

The AMR software suite is easy to implement within large distribution centers, small depots and final sorting locations. It also communicates with other warehouse information systems, such as warehouse management systems (WMS) and enterprise resource planning (ERP).

The suite is combined with seamless web-based visualization software that locates every AMR in real time, monitors its status and reports issues.

COMPLEX SOFTWARE CAPABILITIES

The GENI-Ant™ AMR Sorter Traffic Management System calculates the optimum travel path based on a number of factors, including:

- Priority level of the assignment

- Availability of the AMR

- Travelling distance to loading and unloading stations

- AMR battery level

- Upcoming jobs/ assignments

The GENI-Ant™ AMR Sorter Traffic Management System can change routes in the event of bottlenecks, reassign tasks from non-operating to operating AMRs and so optimizing battery consumption.

The GENI-Ant™ AMR Sorter software suite offers the highest level of performance and flexibility for your plant.