Caja

by Fives

The market demands fulfillment solutions that are not just automated, but truly agile.

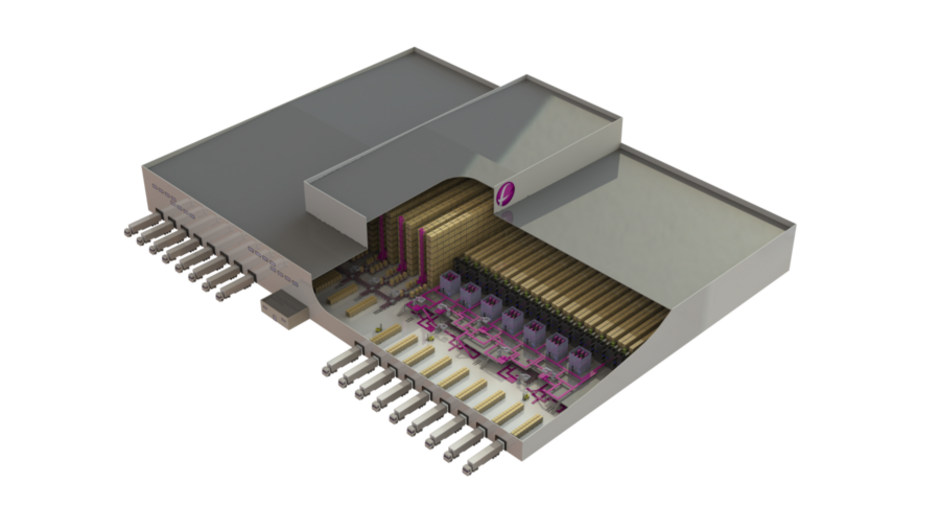

Caja's advanced Goods-to-Person (GTP) system, now an integrated solution within Fives, delivers high-velocity throughput using a radically efficient, software-first approach.

ROI Through Optimization

Unlike traditional GTP solutions that rely on hardware overprovisioning, the Caja solution is based on the principle "Maximum software, minimum hardware". Thanks to an advanced optimization engine, the system achieves the same level of performance with fewer robots and storage locations, while limiting infrastructure changes.

The real-time management of flows and trajectories ensures compliance with SLAs, while reducing the material footprint and CapEx.

Deployment Agility

Designed to easily integrate into your environment, the Caja system is suitable for both brownfield projects and greenfield installations.

- Works with standard shelves and bins (cardboard or plastic)

- Adapts to building constraints: imperfect floors, variable heights, obstacles

- Scalable and modular, with instant adaptation to peaks of activity

A complete robotic solution

The Caja GTP system is a fully synchronized robotic warehouse automation solution, designed for precision and sustained performance. The solution consists of four integrated parts.

Agile Robot Fleet

System performance relies on a fleet of robots with clearly defined roles, avoiding the limitations of single-hardware solutions.

- Cart: fast and agile robot, optimized for horizontal movements and picking on low levels

- Skyler: vertical range robot, designed to access upper storage levels and fully exploit the building’s height

Driven by the Warehouse Control System (WCS), this intelligent cooperation allows optimizing each movement, maximizing throughput and reducing overall hardware investment.

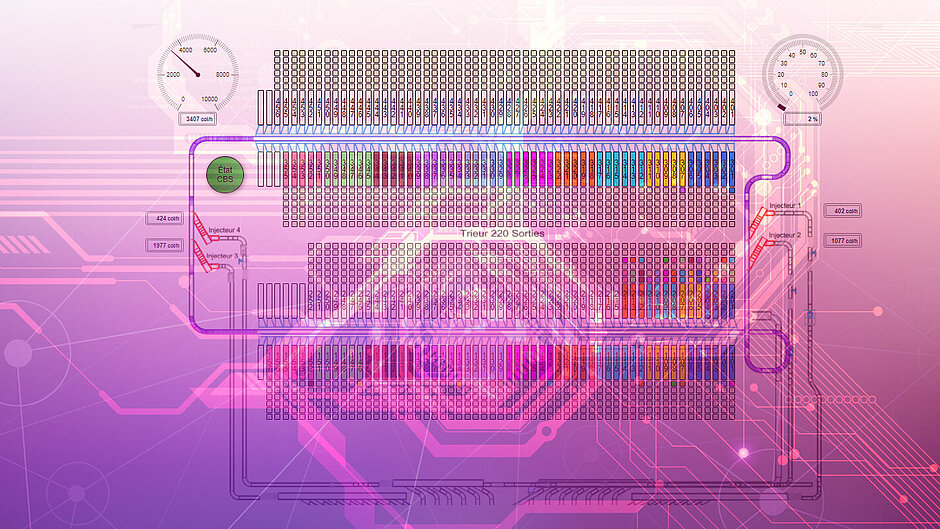

Intelligent WCS, heart of the system

The AI-driven Warehouse Control System is the real brain of the solution. It orchestrates all operations in real time:

- Optimization of order sequencing and load distribution

- Anticipation and elimination of bottlenecks

- Simulation and predictive analysis to adapt resources to changes in activity

This software intelligence ensures the expected performance with a reduced number of robots and storage locations.

Modular storage

The storage area is built around minimal operational and infrastructure impact. Unlike rigid systems, Caja adapts to your existing environment:

- Operation of vertical storage up to 12 meters

- Compatibility with standard, multi-SKU, cardboard or plastic bins

- Rapid deployment on existing shelf structures, without proprietary constraint

ergonomic workstations

Inbound and picking stations constitute the interface between the operator and automation with the objective of maximizing the throughput per operator:

- Maximum operator productivity: elimination of unnecessary trips and search time, items being brought directly to the station

- Support for the complete logistics cycle: inbound, picking, returns, product recalls and consolidation of bins

- Precision and reliability of picking: securing operations thanks to integrated software logic and Put-to-Light systems

- Ergonomics and work comfort: workstations designed to reduce fatigue, improve operator satisfaction and limit errors