Process, product yield & operational flexibility - this is what you look for in a new horizontal or upgraded line. Our range of NeoKoil® CGL, CAGL or CGPL with a horizontal furnace is a cost-effective and flexible solution for producing steel grades with advanced coating development - GA, GL, Al, ZM, AlSi - from building to automotive quality.

Making steel for construction, appliances & auto parts

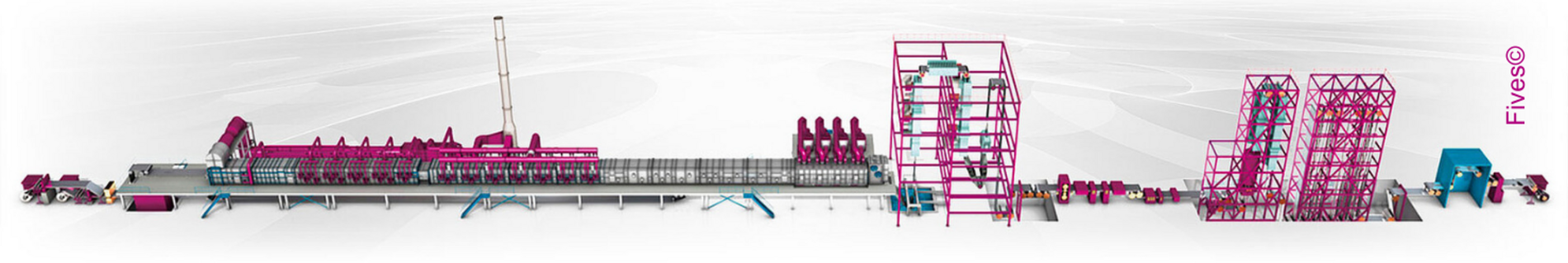

NeoKoil® CGL with a horizontal furnace

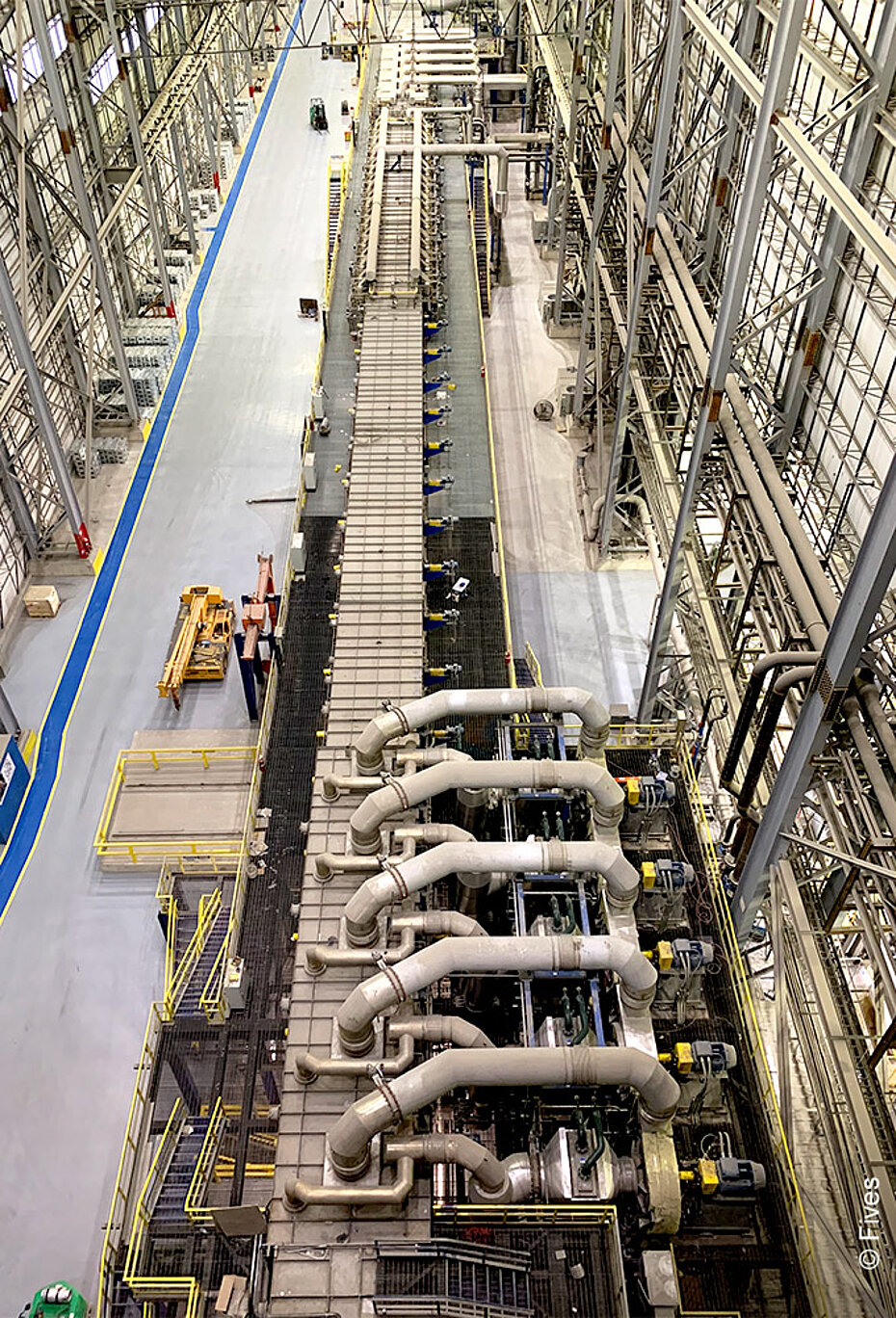

Utilizing our grade development & coating process know-how, smart tools and advanced equipment design we have delivered numerous strip processing lines with a horizontal furnace producing steel grades from building to automotive quality, from compact lines to high-speed lines.

Key technologies

- NeoKlean® system – A degreasing system utilizing a combination of hydro, chemical and mechanical processes. An electrolytic NeoKlean® with improved design ensures the ultimate degree of strip cleanliness.

- Thermal section – Consisting of a non-oxidizing furnace, a radiant tube furnace, a soaking furnace and a rapid cooling section. We use the AdvanTek® DFR (direct fired reducing) combustion system, which gives you homogeneous strip temperature crosswise and proven ability to process strips for automotive parts.

- Aeris® after-pot – An efficient and flexible cooling system to improve strip stability by enabling the reduction of the cooling length.

- Minispangle system – Aiming to minimize ‘spangles’ in galvanized strips to improve the surface quality for coating.

- Skin-pass and strip leveler – Skin-pass mills coupled with strip levelers for a wide variety of annealed and galvanized steel products.

- Side trimmer – Featuring a special design and blade positioning technology that offers clean and accurate edge cutting.