Your people are your biggest source of strength. With the Steel Training Academy, we provide a range of training programs that cover all the challenges you might face over the operational lifecycle. We use virtual reality for a truly immersive approach that ensures your teams are empowered with the knowledge they need to achieve your process’ potential.

EMPOWER YOUR TEAM

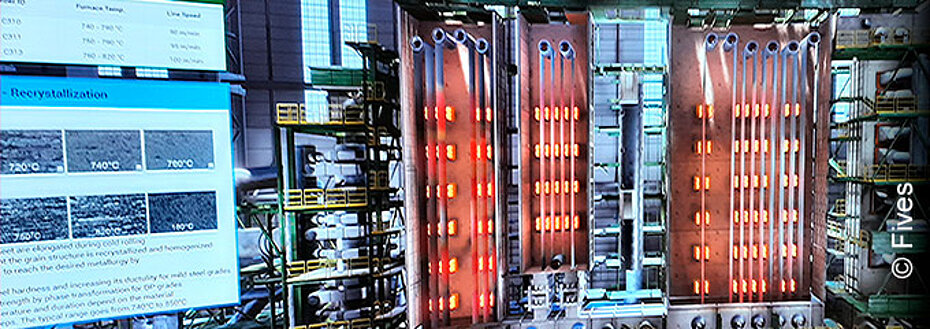

All our training programs are tailored to your needs. We can create virtual factory tours with customized, interactive scenarios that give your personnel the chance to carry out regular operational activities, identify issues and resolve problems, in a safe, realistic environment.

Training in all key areas:

- Process & Product Quality

- Equipment & Digital Solutions

- Immersive Learning

PROCESS & PRODUCT QUALITY

- Metallurgy and metallurgical mechanisms

- Steel manufacturing process

- Product properties and applications

- Quality control & surface aspect analysis

- Defect classification & surface inspection system

- Automotive certification

- Customer technical support for steelmakers

- Quality management system

- Continuous casting process

- Hot & cold rolling process

- Annealing & galvanizing processes

- Pickling & degreasing processes

- Induction heating

- Skin-pass

EQUIPMENT & DIGITAL

Equipment:

- Reheating furnace: operation, combustion & maintenance

- 20Hi cold rolling mills

- Strip drive: operation & maintenance

- Mechanical equipment

- Pickling equipment: operation & maintenance

- Degreasing equipment: operation & maintenance

- Annealing furnace: operation & maintenance

- Induction heating technology

- Galvanization equipment

- Skin-pass mill: operation & maintenance

- Strip coating line equipment

Digital solutions: real-time qualification, smart control & thermal optimizer

training is customized

To your specific needs

- PROCESS & PRODUCT QUALITY

- OPERATION & MAINTENANCE