We know how disruptive unplanned downtime can be. That’s why we offer a variety of preventative maintenance services that take a proactive approach to your machine’s health. Our expert analysis will tell you how to maintain machine productivity with continued high performance.

Contact us to schedule maintenance for your machine

MACHINE HEALTH CHECK AND CERTIFICATION

Regular machine health checks help prevent future production interruptions and breakdowns. Preventing failures before they occur allows you to avoid major and expensive machine repairs.

We use a three-step process to proactively maintain the reliability and performance of your equipment.

An experienced service technician will conduct a thorough evaluation of your machine. This includes a visual inspection of component condition and tests to evaluate the functionality, movement and safety of your machine’s critical components.

Our technician will provide a full report detailing the findings of the evaluation, as well as the recommended maintenance and repairs.

Our GrinderCare team procures parts, schedules service, and provides support during the recommended maintenance and repairs.

If required, we can provide a certifying document detailing the condition of your machine after it has been repaired.

SUPPORTED OEM'S INCLUDE:

Besly - Bryant - Cincinnati - Daisho - Gardner - Giustina - Gold Crown

Landis - Norton - Pratt & Whitney - Warner Swasey

Statistical evaluation

A statistical evaluation determines what your machine’s baseline performance is. This is particularly important ahead of a retool, where changes are being made to the machine. A statistical evaluation provides you with the ability to compare machine functionality post-change. This way, we can ensure that previous performance is matched or exceeded.

Vibration analysis

Over time, excessive amounts of vibration cause machine tools to wear more quickly and can result in poor quality part production. Through our vibration analysis service, we use sensors to gather information about the vibration in your machine. This enables us to identify which adjustments need to be made for your machine to regain optimum stability. Higher stability means greater precision and better efficiency in your production process.

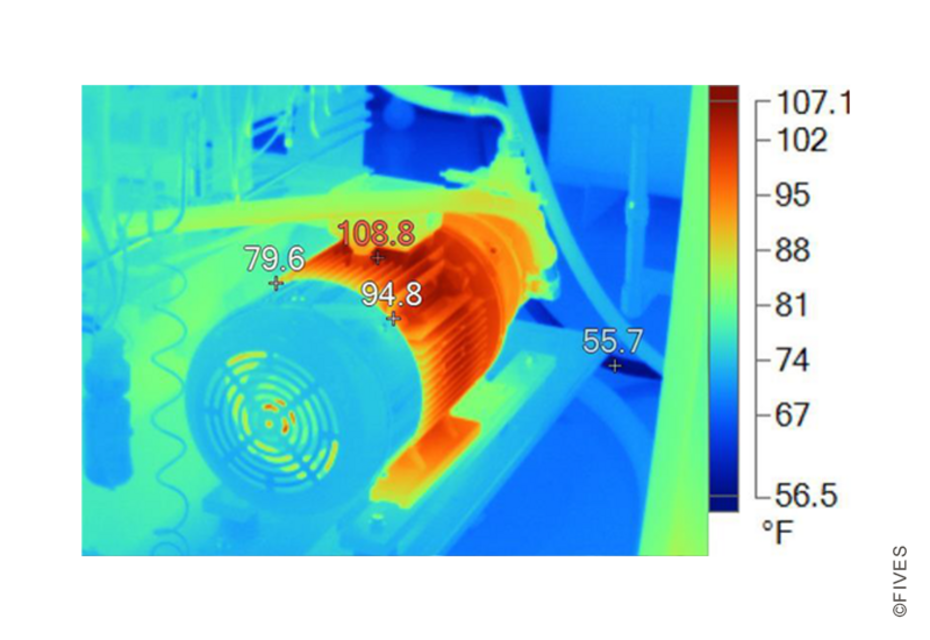

Thermal imaging (Infrared analysis)

We use sophisticated infrared cameras to analyze the health of your machine. Infrared analysis enables our technicians to quickly identify areas of excessive heat or sources of wasted heat energy. This is caused by imminent component failure. Alternatively, we may find areas that are too cool, which would indicate a coolant leak.

Based on the infrared results, our technicians will work out the cause of the problem and provide replacement parts to fix it.