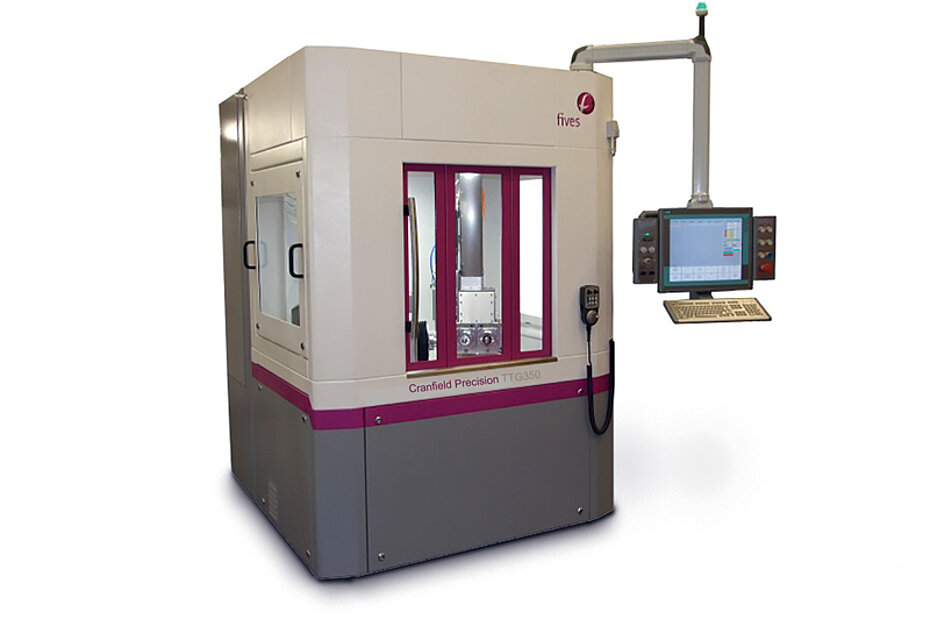

With high stiffness, damping, and thermal stability built in, the Cranfield Precision TTG is the ultra-precision aspheric and freeform optics grinding solution. Engineered specifically for speciality optics and molds, medical and aerospace components.

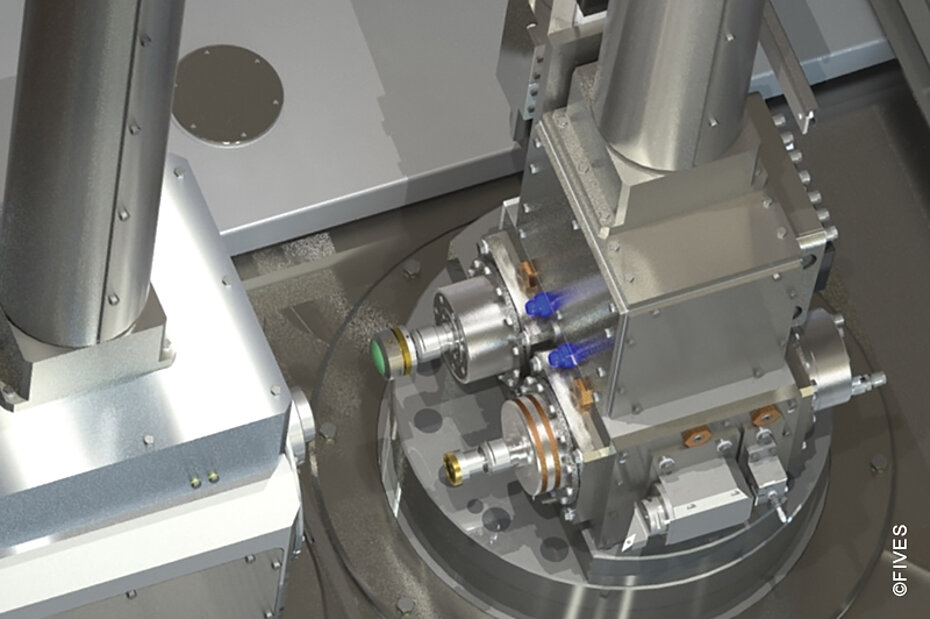

Unique patented highly symmetric machine configuration

The Cranfield Precision TTG benefits from a symmetric machine configuration that gives you the utmost flexibility and precision in freeform optics grinding.

To further optimize stiffness, the rotary axes have large hydrostatic thrust bearings mounted directly on the machine base. This gives highly stiff, damped axes an excellent bearing ratio in all directions for ultimate precision and repeatability.

Check out our Cranfield Precision TTG flyer to learn more.

Optimal flexibility

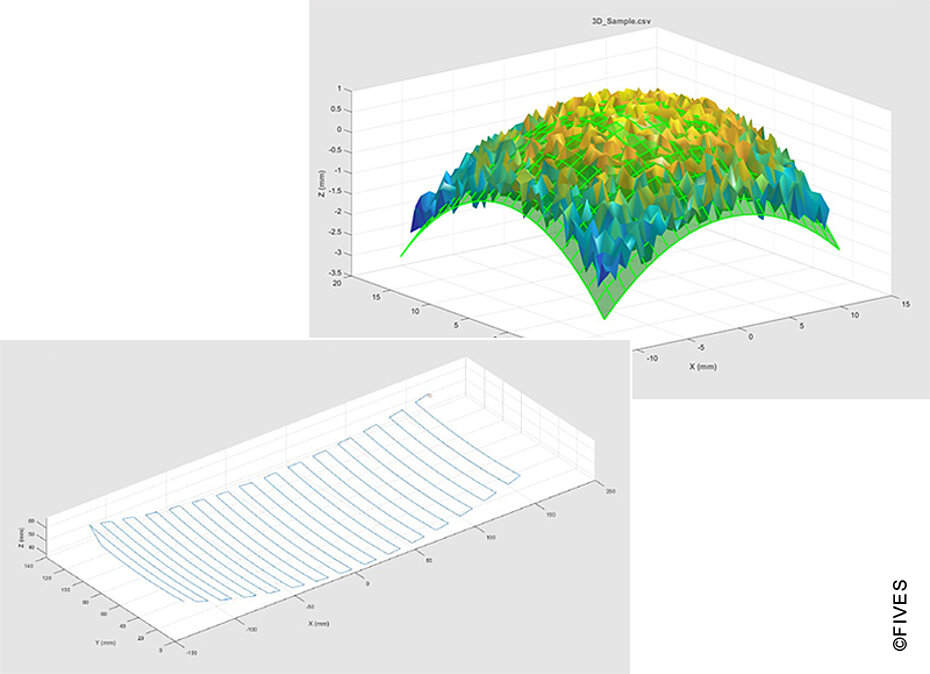

To ensure you get the most operational capabilities out of your investment, we have also engineered this machine for optimum functional flexibility. It is capable of optical grinding and diamond turning with very low sub-surface damage, micro-milling and pre-polishing, all on the same platform.

In addition, the Cranfield Precision TTG 350 has the capacity to produce components up to 350mm in diameter.

Precise and flexible

The Cranfield Precision TTG achieves precision grinding of complex freeform surfaces thanks to the precise interpolation control of the two rotary turret axes. These axes work in combination with the linear axis and the rotary component workhead.

In addition, our advanced software package, MöbiusCAM, brings further precision and flexibility to the machine. The software is designed to facilitate programming for ultra-precise optics grinding and on-machine metrology.

process options include:

- Plunge mode: Plano, spheres (concave / convex)

- Generate mode: concave / convex aspheres, spheres

- Freeform mode: Surface generation

- Edging: Circular boundary

- Edging: Non symmetrical edge profiling

- Chamfering: (circular boundary)

- Coring

- Flat Milling

- Scooping

- Slicing and dicing

- Prism cutting/grinding

- Milling

- Diamond turning

- Hard turning

- Pre-polishing

EXCEPTIONAL THERMAL STABILITY

The Cranfield Precision TTG is designed for thermal stability from the ground up. Even the machine base is thermally isolated.

This focus is carried all the way through the machine’s design, and then further enhanced by the temperature-controlled hydrostatic bearing oil. In turn, this ensures the optimum working temperature of the machine components at all times.

Cranfield Precision TTG

The Cranfield Precision TTG is used to grind head-up display mirror molds for the automotive market. The complex and freeform molds are ground using unique grinding machinery that has class-leading stiffness, damping and thermal stability.

specifications

|

| ||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||