Our vertical single disc grinding machines are accurate and reliable with exceptional stiffness. Available with an ID or OD clamping system, they are engineered to ensure exceptionally tight squareness and high efficiency.

Vertical single disc grinding – optimum efficiency, maximum precision

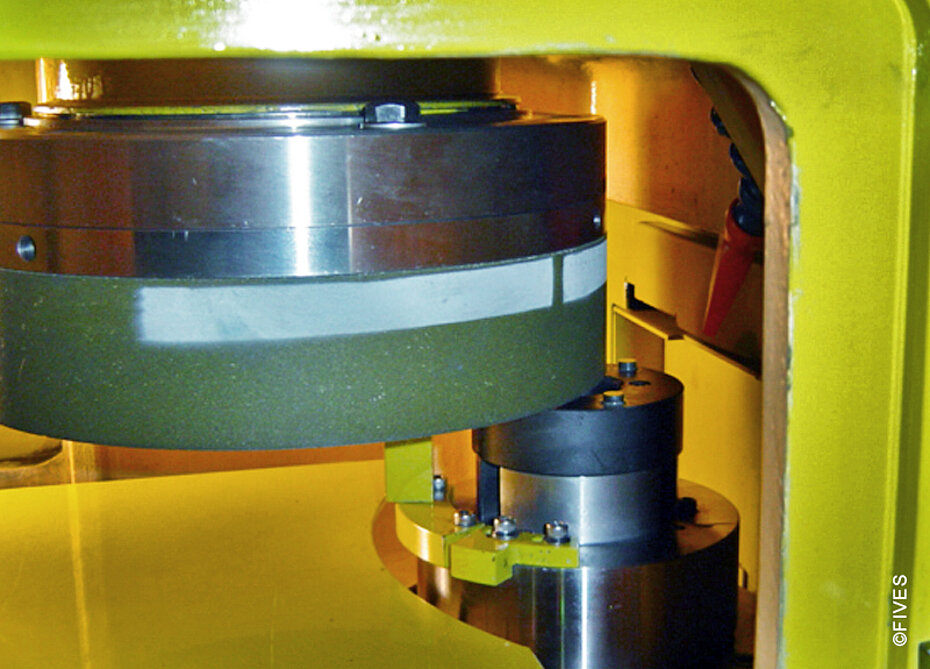

The machines’ cast iron structure ensures excellent stiffness, for high precision and high stock removal. Our vertical single disc machines are ideal for flat surface grinding of gears, rotors and other workpieces that require precise squareness.

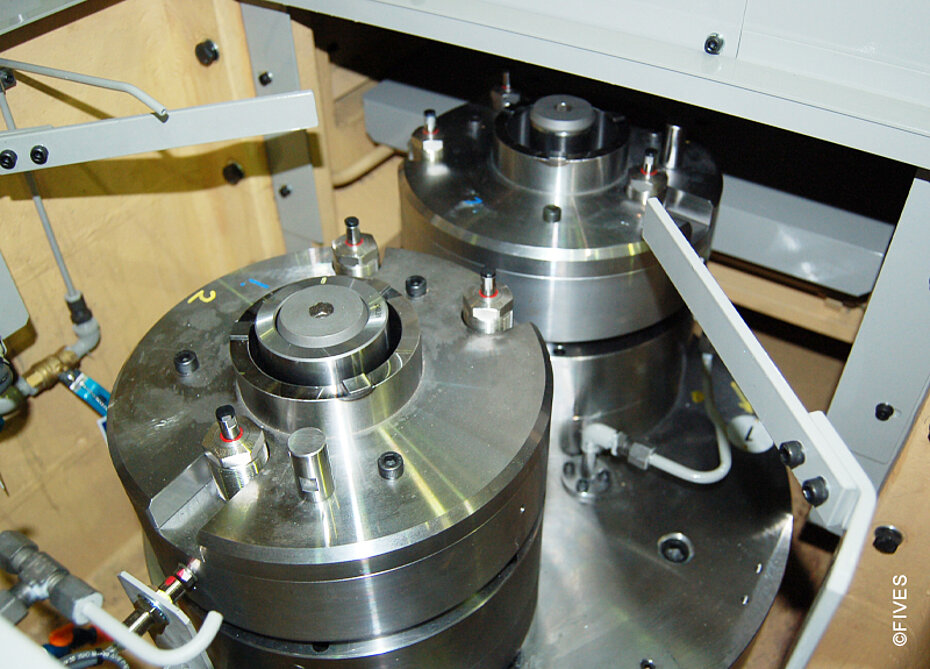

Our VSD grinders can also be equipped with multi-component clamping, to further reduce cycle time and optimize productivity.

Check out our Vertical single disc flyer to learn more.

Gardner or Giustina grinding machines will be proposed according to the standards in the specific geographical areas.

Flexibility, with a small footprint

Our vertical single disc grinding machines have a small footprint and a completely modular setup. As a result, these flexible systems can be engineered to meet your specific grinding requirements.

Superior machine rigidity with exceptional parallelism and flatness

Additional keys benefits include:

- A high resistance cast iron machine structure

- Grinding wheel movement that is servo-controlled

- CBN, diamond or conventional grinding wheels

- Automatic or manual loading/unloading system

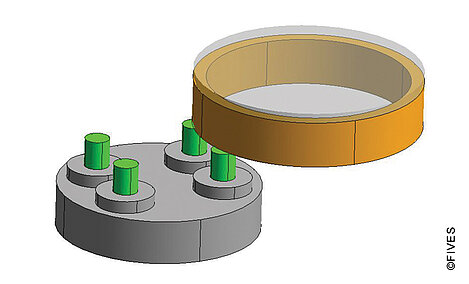

- Engineered clamping system

Index table work drive

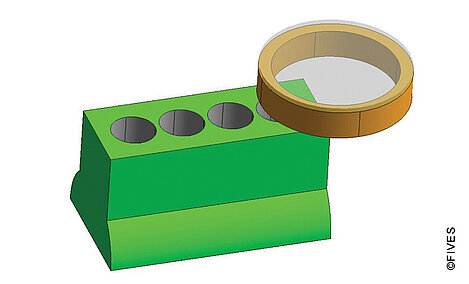

Table traverse

VARIOUS WORKING MODES

Our VSD machines are used to surface grind components with different working methods that include:

specifications

| VSD305 | VSD355 | VSD455 | VSD585 | |

| MACHINING CAPACITY | ||||

Max. workpiece diameter | Joint face fixture only | 225 mm | 250 mm | Upon requirements |

Max. workpiece thickness | 125 mm | 125 mm | ||

| wheelHEAD | ||||

Wheel diameter | 305 mm | 355 mm | 455 mm | 585 mm |

Max. power | 7.5 kW | 7.5 kW | 11 kW | 22 kW |

| LINEAR AXES | ||||

Positioning resolution | 1 μm | 1 μm | 1 μm | 1 μm |

| COOLANT | ||||

Delivery | 200 l/min 2.5 bar | 200 l/min 2.5 bar | 200 l/min 2.5 bar | 200 l/min 2.5 bar |

| Dimensions | ||||

Dimensions (W x D x H) | 1,400 x 1,500 x 2,540 mm | 2,000 x 2,000 x 2,600 mm | 1,900 x 2,640 x 2,610 mm | 3,080 x 2,640 x 2,610 mm |

Machine weight | 5,500 kg | 5,500 kg | 5,500 kg | 12,000 kg |

| VSD305 | VSD355 | VSD455 | VSD585 | |

| MACHINING CAPACITY | ||||

Max. workpiece diameter | Joint face fixture only | 8.9" | 9.8" | Upon requirements |

Max. workpiece thickness | 4.9" | 4.9" | ||

| wheelHEAD | ||||

Wheel diameter | 12" | 14" | 17.9" | 23" |

Max. power | 7.5 kW | 7.5 kW | 11 kW | 22 kW |

| LINEAR AXES | ||||

Positioning resolution | 1 μm | 1 μm | 1 μm | 1 μm |

| COOLANT | ||||

Delivery | 200 l/min 2.5 bar | 200 l/min 2.5 bar | 200 l/min 2.5 bar | 200 l/min 2.5 bar |

| Dimensions | ||||

Dimensions (W x D x H) | 4.6' x 4.9' x 8.3' | 6.6' x 6.6' x 8.5' | 6.2' x 8.7' x 8.6' | 10.1' x 8.7' x 8.6' |

Machine weight | 12,125 lb | 12,125 lb | 12,125 lb | 26,456 lb |