Reliable vertical double disc grinding that offers high stock removal on large and small parts. Our flexible range of machines utilize a modular system that can be engineered to suit your production process.

MODULAR DESIGN FOR ENGINEERED SOLUTIONS

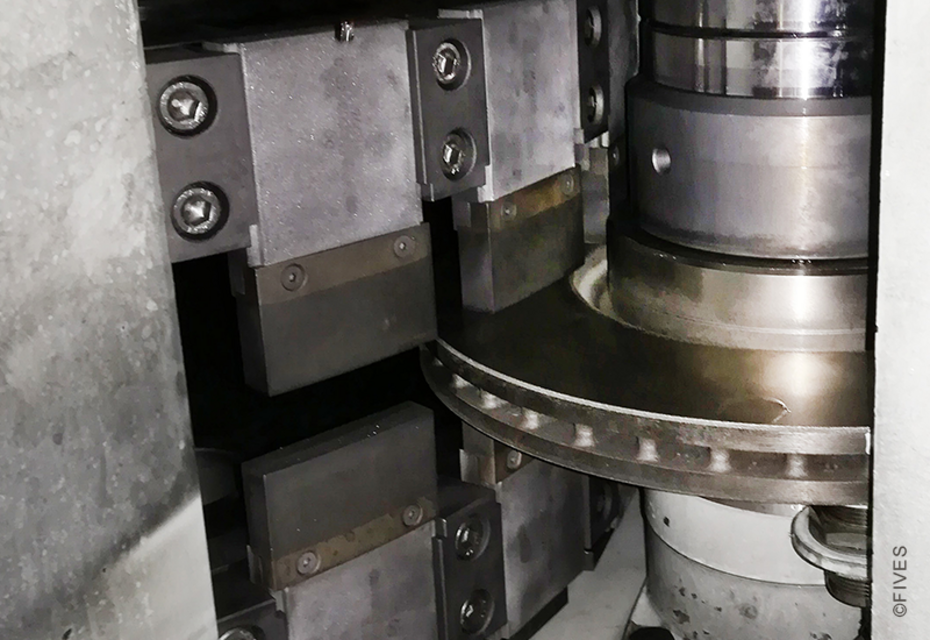

For superior rigidity, our line of vertical double disc grinding machines is built on a three-block cast iron box type framing structure. This ensures our VDD machines have exceptional stiffness and robustness. We offer both conventional and super abrasive grinding wheel (CBN & diamond) options. As a result, you get reduced cycle time, higher throughput and increased cost efficiency.

Check out our Vertical double disc flyer to learn more.

Gardner, Giustina or Daisho grinding machines will be proposed according to the standards in the specific geographical areas.

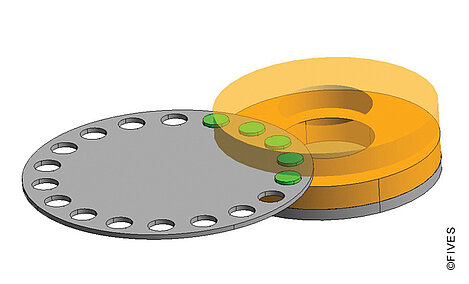

COATED BRAKE DISC GRINDING

Our expert engineers have developed new working parameters and wheel specifications using our current grinder product range that will meet the grinding requirements of the new dust-free composite coating material.

Contact the Fives team to schedule a demo or test grind to see how we can help you with your coated brake disc applications.

flat and parallel surface grinding

Our flexible vertical double disc machines are ideal for high precision grinding for a variety of flat-surface components including:

- Rotors

- Stators

- VVT components

- Bearings

- Spacers

- Pump parts

- Connecting rods

- Piston rings

- And many other components

MACHINE HIGHLIGHTS

Our machines are available in multiples sizes and can be engineered to suit your production needs. Additional key benefits include:

- A high resistance cast iron machine structure

- CBN, diamond or conventional grinding wheels

- Servo-controlled wheelhead and dresser positioning

- Automatic or manual loading/unloading system

- Small footprint

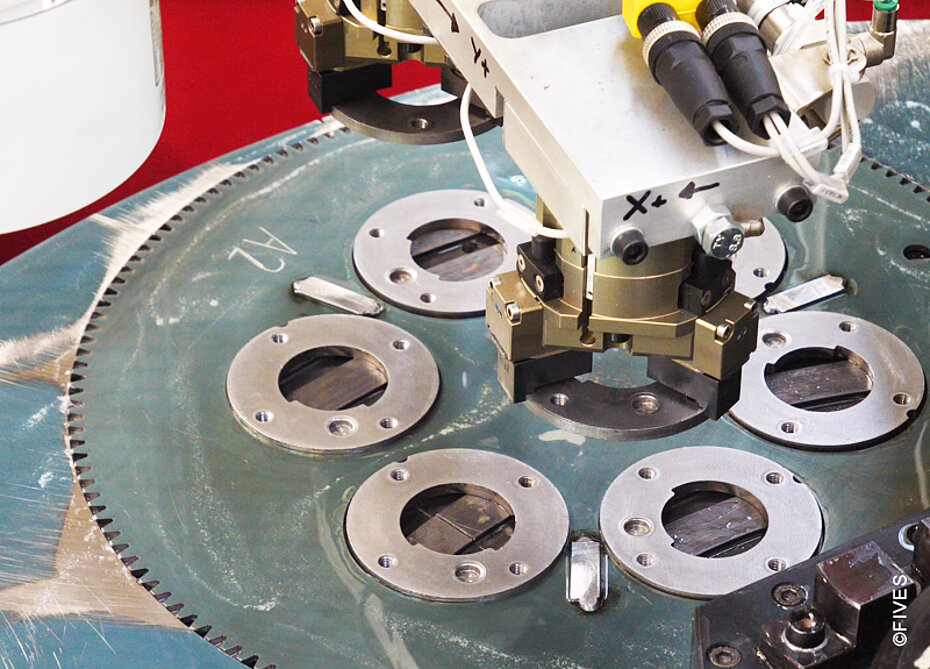

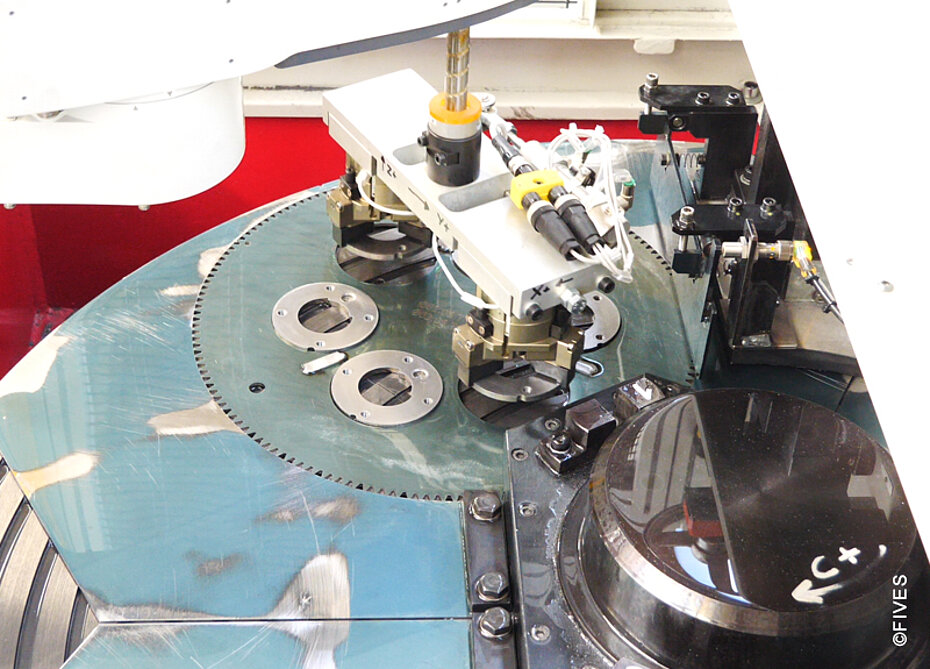

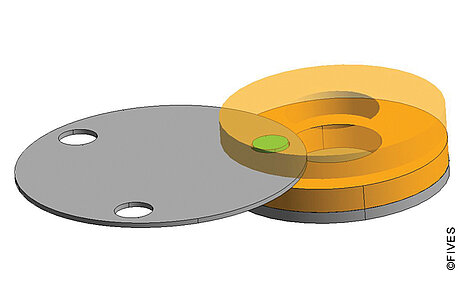

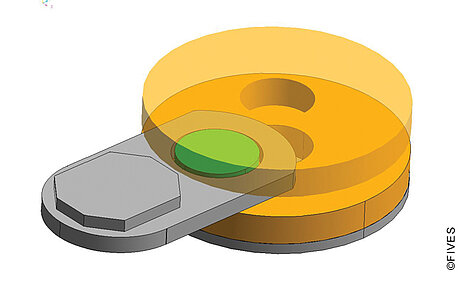

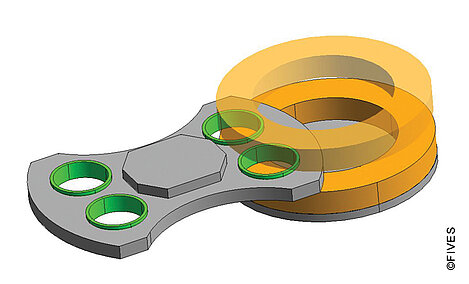

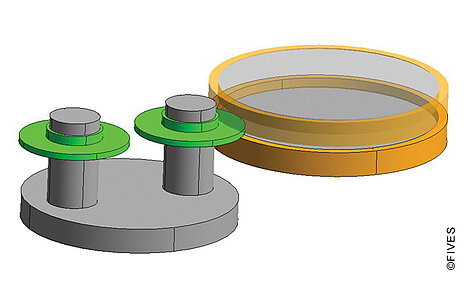

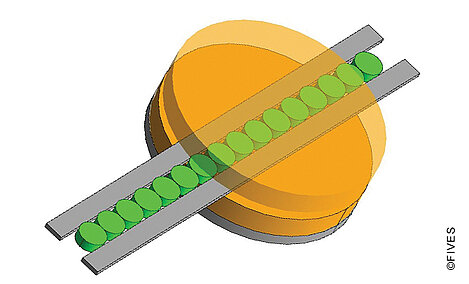

Rotary through-feed

Index carrier

Oscillating infeed carrier

Workpiece rotating index

Index table work drive

Through-feed

VARIOUS WORKING MODES

Our VDD machines are used to surface grind workpieces with different working methods that include:

Vertical Double Disc Grinder

Our reliable vertical double disc grinders offer high stock removal on large & small parts and are available in a range of sizes with various working methods to suit your production needs.

specifications

| Vertical Models | VDD305 | VDD355 | VDD455 | VDD510 | VDD585 | VDD760 |

| WHEELHEAD | ||||||

| Wheel Ø | 305 mm | 355 mm | 455 mm | 510 mm | 585 mm | 760 mm |

| Max. power grinding wheel | 7.5 kW | 11 kW | 15 kW | 15 kW | 37 kW | 45 kW |

| GRINDER WORKPIECE CAPACITY | ||||||

| Max. OD (Infeed) | 80 mm | 120 mm | 180 mm | 180 mm | 300 mm | 400 mm |

| Max. OD (Through-feed) | 25 mm | 40 mm | 50 mm | 60 mm | 120 mm | 240 mm |

| Max. thickness | 20 mm | 25 mm | 40 mm | 40 mm | 65 mm | 100 mm |

| Min. thickness (Infeed) | 2 mm | 2.5 mm | 2.5 mm | 2.5 mm | 2.5 mm | 2.5 mm |

| Min. thickness (Through-feed) | 0.8 mm | 0.8 mm | 0.8 mm | 1 mm | 1 mm | 1 mm |

| MACHINE DIMENSIONS | ||||||

| Width | 1,550 mm | 1,550 mm | 1,550 mm | 1,550 mm | 1,900 mm | 2,700 mm |

| Depth | 1,625 mm | 1,625 mm | 1,625 mm | 1,625 mm | 2,700 mm | 2,700 mm |

| Height | 2,200 mm | 2,200 mm | 2,200 mm | 2,200 mm | 2,800 mm | 3,200 mm |

| Weight | 5,500 kg | 5,500 kg | 5,500 kg | 5,500 kg | 12,000 kg | 15,000 kg |

| Vertical Models | VDD305 | VDD355 | VDD455 | VDD510 | VDD585 | VDD760 |

| WHEELHEAD | ||||||

| Wheel Ø | 12 in | 14 in | 18 in | 20 in | 23 in | 30 in |

| Max. power grinding wheel | 7.5 kW | 11 kW | 15 kW | 15 kW | 37 kW | 45 kW |

| GRINDER WORKPIECE CAPACITY | ||||||

| Max. OD (Infeed) | 3.1 in | 4.7 in | 7.1 in | 7.1 in | 11.8 in | 15.7 in |

| Max. OD (Through-feed) | 1 in | 1.6 in | 2 in | 2.4 in | 4.7 in | 9.4 in |

| Max. thickness | 0.8 in | 1 in | 1.6 in | 1.6 in | 2.6 in | 3.9 in |

| Min. thickness (Infeed) | 0.08 in | 0.1 in | 0.1 in | 0.1 in | 0.1 in | 0.1 in |

| Min. thickness (Through-feed) | 0.03 in | 0.03 in | 0.03 in | 0.04 in | 0.04 in | 0.04 in |

| MACHINE DIMENSIONS | ||||||

| Width | 61 in | 61 in | 61 in | 61 in | 75 in | 106 in |

| Depth | 64 in | 64 in | 64 in | 64 in | 106 in | 106 in |

| Height | 87 in | 87 in | 87 in | 87 in | 110 in | 126 in |

| Weight | 12,125 lbs | 12,125 lbs | 12,125 lbs | 12,125 lbs | 26,455 lbs | 33,070 lbs |