Accurate, flexible and compact, the LT1e is ideal for high performance camshaft grinding, including concentric and non-concentric components.

Unrivalled quality and cycle time in a compact solution

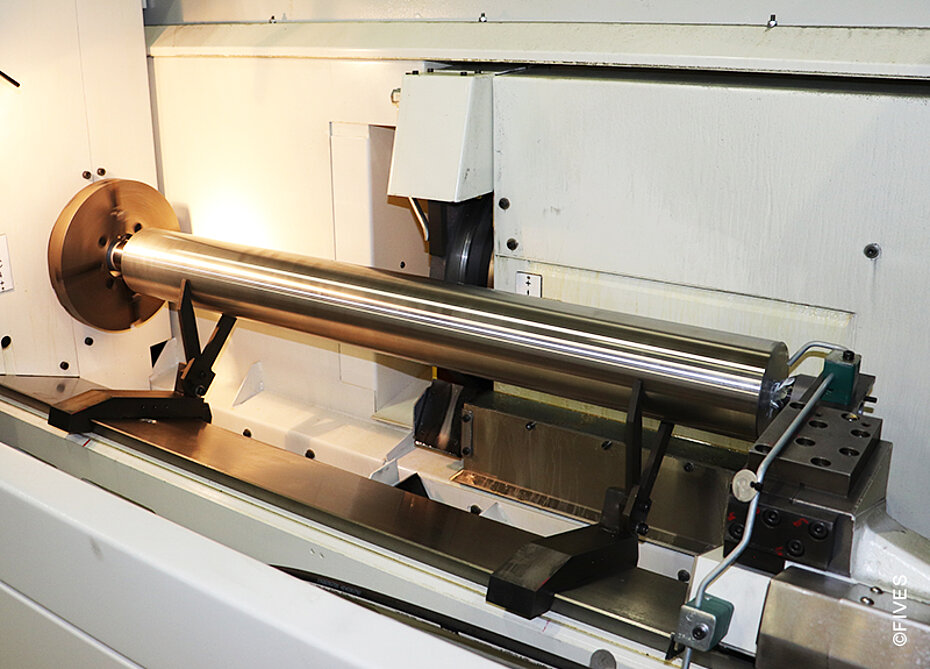

The Landis LT1e takes the technology of a larger machine and incorporates it into a reliable and compact grinding solution. Providing high productivity and precision grinding for smaller 4 or 6 cylinder camshafts, including short-run production of concentric and non-concentric diameter shafts.

Check out our Landis LT1e flyer to learn more.

High performance camshaft grinding with the Landis LT1e

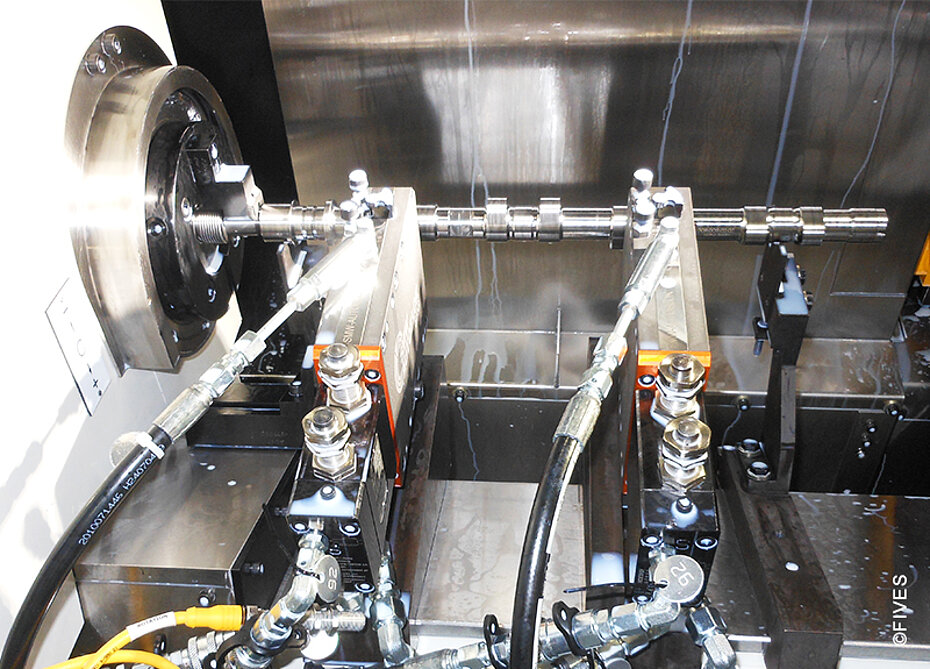

Designed for high-volume production of camshafts and other precision components with:

- Concentric & non-concentric diameters

- Eccentrics

- Profiles

- Tapers

- Chamfers

- Faces

flexibility for intricate applications

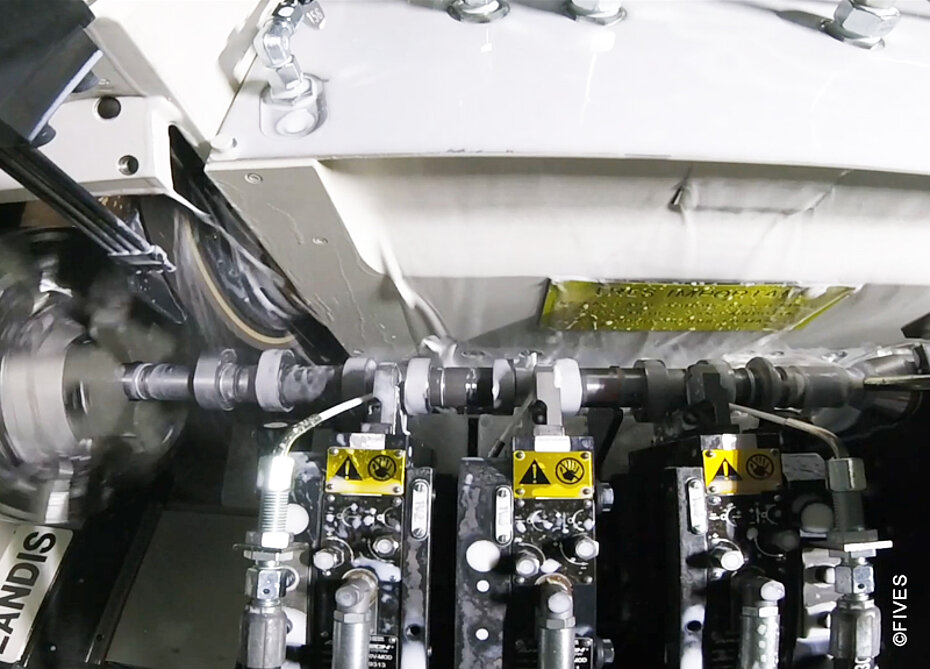

With a fully hydrostatic spindle and way system, in addition to linear motor technology, the Landis LT1e provides reliable high-precision grinding. An optional swivelling wheelhead with infinitely variable hydrostatic control makes repositioning easy and adds flexibility for intricate applications.

The Landis LT1e uses CBN grinding wheels and is also available in two component length capacities; 500 mm and up to 1,200 for heavier-duty operations.

optimized cycle time

Ergonomic loading helps ensure cycle time is kept low and parasitic time is reduced to a minimum. The Landis LT1e also features easy access for simple, one-man wheel change.

Dual spindle options are available.

Check out the testimonial from Isky Racing Cams

Nolan Jamora from Isky Racing Cams discusses his experience purchasing his first CNC cam grinder from the Fives Landis Corp team, located in the United States. Nolan was looking for the trifecta, a machine that was more accurate, higher precision than anything in the market, with higher production rates and lower costs. He found exactly what he was looking for at Fives with the Landis LT1e.

Landis LT1e

Providing unrivalled quality and cycle time in a compact solution. The LT1e is ideal for high productivity and precision grinding for smaller 4 or 6 cylinder camshafts, including short production runs of concentric and non-concentric diameter shafts.

specifications

| Landis LT1e 500 | Landis LT1e 1200 | |

| GRINDING CAPACITY | ||

Max. component swing | 150 mm | |

Max. grinding length | 500 mm | 1,200 mm |

Center height | 220 mm | |

Max. workpiece weight | 250 kg | |

| CBN grinding wheel | ||

Wheel type | CBN | |

Max. wheel Ø | 350 mm | |

Max. wheel width | 65 mm | |

Wheel surface speed | 200 m/sec | |

Spindle power | 40 kW | |

| WORKHEAD & FOOTSTOCK | ||

Type | Live spindle | |

Workhead speed range | 0 - 600 rpm | |

Workhead drive power | 5.5 kW | |

Max. workhead motor torque | 230 Nm | |

Type | Hydraulic operated | |

Footstock stroke | 50 / 80 / 160 mm | |

| AXES | ||

Linear guide ways | Hydrostatic | |

Grinding spindle | Hydrostatic | |

Drive | Linear motor | |

| Dimensions | ||

Dimensions (W x D x H) | 4,330 x 5,650 x 2,385 mm | 5,530 x 5,650 x 2,465 mm |

Machine weight | 9,800 kg | 12,000 kg |

| Landis LT1e 500 | Landis LT1e 1200 | |

| GRINDING CAPACITY | ||

Max. component swing | 5.9" | |

Max. grinding length | 19.7" | 47.2" |

Center height | 8.7" | |

Max. workpiece weight | 551 lb | |

| CBN grinding wheel | ||

Wheel type | CBN | |

Max. wheel Ø | 13.8" | |

Max. wheel width | 2.6" | |

Wheel surface speed | 656 ft/sec | |

Spindle power | 40 kW | |

| WORKHEAD & FOOTSTOCK | ||

Type | Live spindle | |

Workhead speed range | 0 - 600 rpm | |

Workhead drive power | 5.5 kW | |

Max. workhead motor torque | 230 Nm | |

Type | Hydraulic operated | |

Footstock stroke | 2" / 3.2" / 6.3" | |

| AXES | ||

Linear guide ways | Hydrostatic | |

Grinding spindle | Hydrostatic | |

Drive | Linear motor | |

| Dimensions | ||

Dimensions (W x D x H) | 14' x 18.5' x 7.8' | 18' x 18.5' x 8.2' |

Machine weight | 21,605 lb | 26,456 lb |