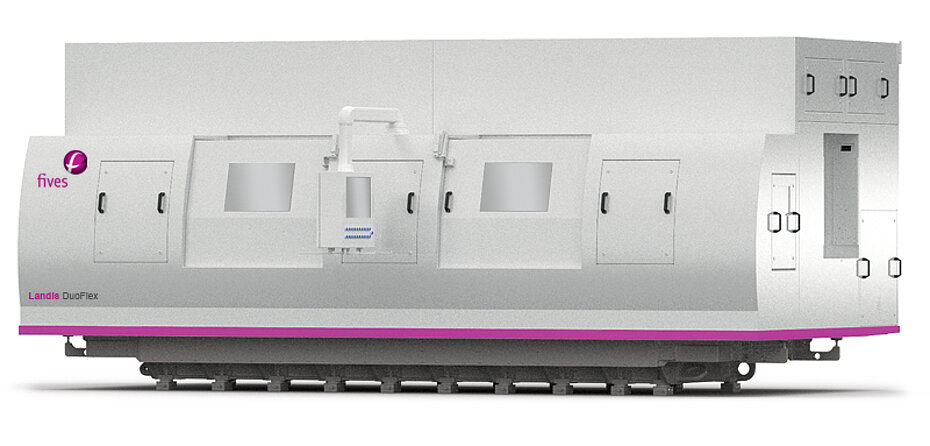

With the capabilities and precision of two Landis LT2e grinding machines in one flexible and compact package, the Landis DuoFlex increases the possibilities for concentric and non-concentric workpiece processing.

Two independent workstations, one grinding machine

The Landis DuoFlex incorporates two independent LT2e workstations, with up to four wheelheads and B-axis options, into one grinding machine. In doing so, it expands what is possible on a single unit with the capability to grind all features: OD plunge, angle spindle plunge, axial ‘bump’ grind, orbital and other non-round shapes. There is also an option for polishing on this machine.

Check out our Landis DuoFLEX flyer to learn more.

Proven reliability and precision

The design of the Landis DuoFLEX is based on tried-and-tested Landis machine technologies. This includes LT2e table tooling and geometry, LT2e-based 28 kW wheel spindles, and a slightly modified Landis Flex 2500 bed. The enclosure also uses LT2 details, where possible.

HIGHLY CONFIGURABLE PLATFORM

The Landis DuoFLEX is a highly configurable platform. In addition to two- and four-wheelhead options, a three-wheelhead configuration is available with right, left and center wheelheads.

Wheelhead slides feature linear bearings on the z-axis, hydrostatic linear bearings on the x-axis, and Fibro swivel with 3-degree Hirth coupling and worm drive.

Additional key machine features include:

- Linear motors on all feed and traverse axes

- Hydrostatic wheel spindles and wheel feeds

- High precision linear rail traverse axes

- CBN wheelhead

- A festoon arrangement of power cables to reduce assembly time

- Reduced power consumption and overall floor space compared to two equivalent machines

specifications

|

| ||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||