Capture the advantages of unlimited flexibility, sub-micron precision and the ability to perform multiple operations in a single fixturing with the Landis LTT multi-spindle twin turret grinding solution.

High performance grinding solution with one-of-a-kind capabilities

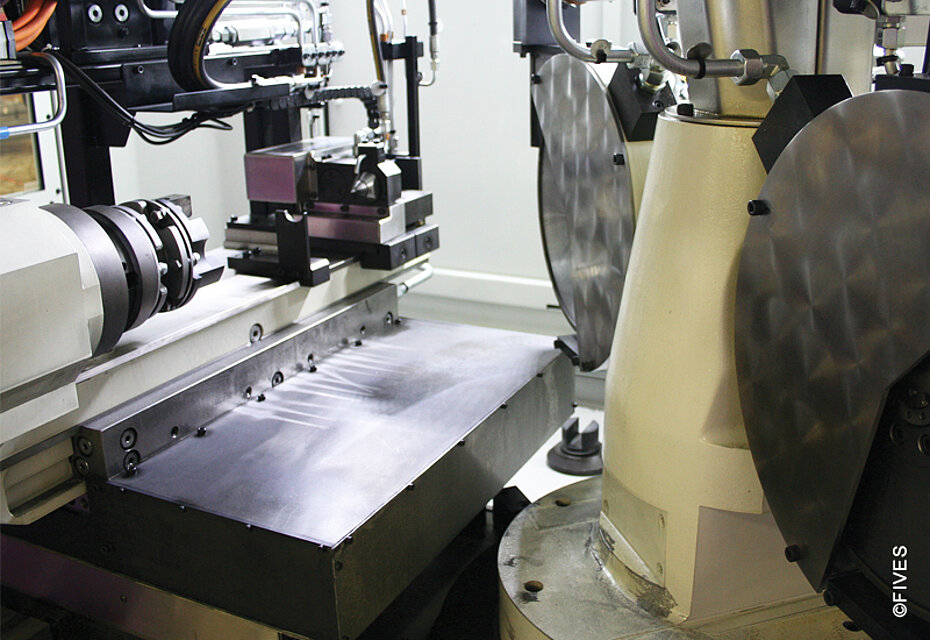

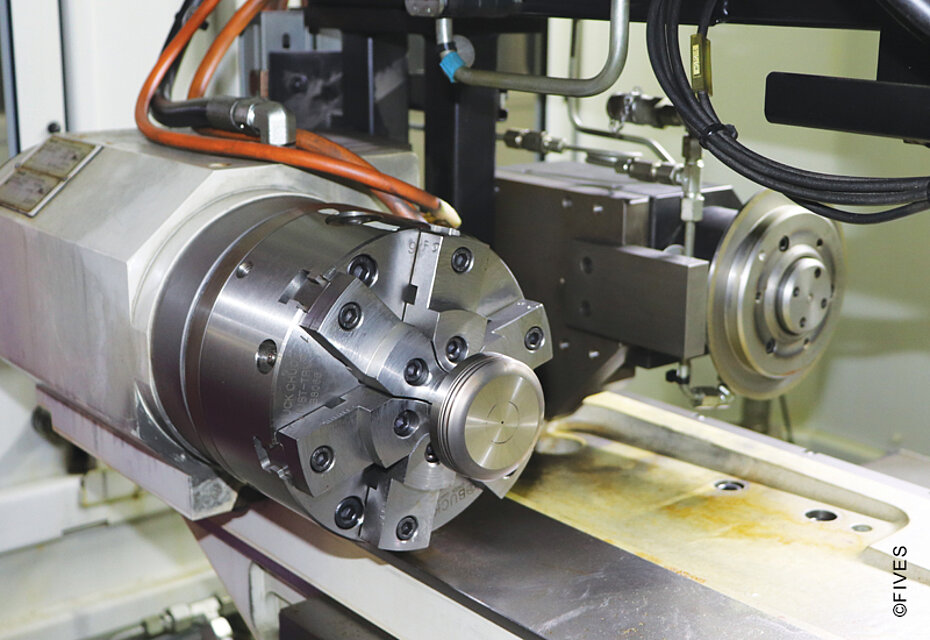

The Landis LTT is a flexible solution for grinding ID/ODs, faces, tapers, including concentric and eccentric diameters and contours, to sub-micron tolerances in a single clamping.

The two rotary turrets are equipped with integrated servomotors and X-axis hydrostatic guideways with linear in-feeds to enable simultaneous contouring of workpieces. All motors are backlash free for all motions, using ultra-stiff hydrostatic spindle bearings.

Check out our Landis LTT flyer to learn more.

a fully-integrated package

High performance control is achieved with the Landis 6400 open architecture control software, in a fully-integrated package. The software ensures maximum delivery with advanced monitoring capabilities and comprehensive sensor integration, as well as easy programming.

Additional options include a variety of in-process gauging and touch probes, as well as auto wheel balancers. Plus, it’s all backed up by 32 kW of available power to guarantee constant wheel speeds of up to 120 m/sec.

machine highlights

The Landis LTT can cater to components of up 400mm and 150kg with a maximum swing diameter of 180mm.

Additional features include:

- A variety of headstock and footstock options

- Arobotec workrest

- Filtration systems

- Automatic loading / unloading

specifications

|

| ||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||