Part of the Cincinnati family of machines, the R125 benefits from the company’s 100 years of experience and innovation in centerless grinding for large components. This machine lives up to our reputation for superior accuracy, high reliability and ease of use.

High precision centerless grinding

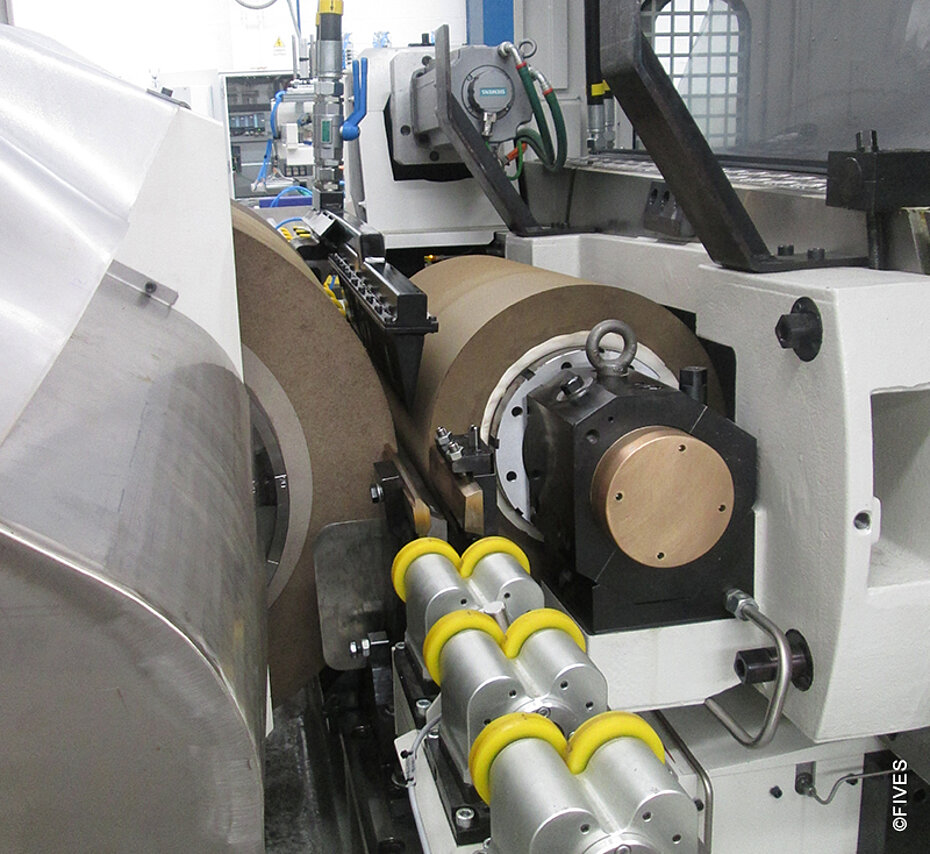

The Cincinnati R125 is engineered for high durability and a solid operation. Built with a cast iron base, the machine provides high thermal and mechanical stability, as well as vibration dampening and tight tolerancing. High machine stiffness ensures optimum accuracy, in addition to fast production rates and high stock removal.

Check out our Cincinnati R125 flyer to learn more.

large component grinding to fit your needs

Like the other Cincinnati machines, the R125 can be adapted to both the plunge-feed and in-feed grinding processes. However, as a larger machine than the Viking and RK models, it can accommodate much larger components. The Cincinnati R125 is the ideal solution for grinding any type of bar, tube, camshaft, gear shaft or roller up to 300mm in length.

A COMPLETE, AUTOMATED SOLUTION FOR ULTIMATE ACCURACY

We can provide the expertise and the automation to make your process and operation as easy as possible. We offer turnkey solutions that include components to automate your grinding operation, including infeed / outfeed systems and a gauging system.

Easily integrate your Cincinnati R125 into new and existing product lines. Its open architecture is compatible with a number of different control systems, including Landis 6400, Allen Bradley, Siemens and Fanuc.

flexibility to GRIND A WIDE VARIETY OF MATERIALS

The Cincinnati R125 uses conventional wheels. This enables the machine to grind a wide variety of materials, including stainless steel, inconel and titanium. With the hydrodynamic oil bearings installed for maximum precision and stiffness, the machine is ideal for grinding large or long parts that require very high accuracy.

This machine is used to grind components for the medical and aerospace industries. It is also ideal for use in the automotive, agricultural, appliance, power tools and fluid power sectors.

Additional key machine features include:

- Spindles with hydrodynamic lubrication mounted on double support

- Automatic taper compensation

- Grinding wheel with dynamic balancing device, max. width 660mm

- Control wheel. max. width 660mm, tilt angle up to 8°

CONTINUAL AFTERMARKET SUPPORT

In addition to building new machines, we provide after sales service as well as service of existing machines. Also, we can retool or refurbish existing machines, and pride ourselves on our after-market support.

specifications

| Cincinnati R125 500 | Cincinnati R125 660 | |

| WORKING CAPACITY | ||

Min. / Max. outer diameter | 2 - 250 mm | 2 - 300 mm |

| grinding wheel | ||

Sizes / width | 508 mm | 650 mm |

Max. / Min. OD | 610 / 410 mm | 610 / 410 mm |

Motor power | 110 kW | 110 kW |

Peripheral speed | 45 (60) m/sec | 45 (60) m/sec |

| Regulating Wheel | ||

Sizes / width | 508 mm | 508 mm |

Max. / Min. OD | 355 / 250 mm | 355 / 250 mm |

Motor power | 3.3 kW | 3.3 kW |

Operating speed | 10 - 300 rpm | 10 - 300 rpm |

| Infeeds | ||

Max. plunge infeed | 1,500 mm/min | 1,500 mm/min |

Min. plunge infeed | 0.1 mm/min | 0.1 mm/min |

| Dimensions | ||

Dimensions (W x D x H) | 3,400 x 1,800 x 1,900 mm | 3,400 x 2,000 x 1,900 mm |

Machine weight | 18,000 kg | 20,000 kg |

| Cincinnati R125 500 | Cincinnati R125 660 | |

| WORKING CAPACITY | ||

Min. / Max. outer diameter | 0.08” - 9.5” | 0.08” - 11.8” |

| grinding wheel | ||

Sizes / width | 20” | 26.6” |

Max. / Min. OD | 24 “ / 16” | 24 “ / 16” |

Motor power | 110 kW | 110 kW |

Peripheral speed | 148 ft/sec | 148 ft/sec |

| Regulating Wheel | ||

Sizes / width | 20” | 20” |

Max. / Min. OD | 14” / 9.8” | 14” / 9.8” |

Motor power | 3.3 kW | 3.3 kW |

Operating speed | 10 - 300 rpm | 10 - 300 rpm |

| Infeeds | ||

Max. plunge infeed | 4.9 ft/min | 4.9 ft/min |

Min. plunge infeed | 0.004 in/min | 0.004 in/min |

| Dimensions | ||

Dimensions (W x D x H) | 11.2’ x 5.9’ x 6.2’ | 11.2’ x 6.6’ x 6.2’ |

Machine weight | 39,683 lb | 44,092 lb |