High speed and capacity horizontal and vertical strip accumulators offer careful handling and ensure optimum efficiency in your mill feed. Whatever your layout and process requirements, we supply a strip accumulator to suit your needs.

High-speed strip accumulators for optimal productivity

Each model in fully integrated to the tube mill, enabling end shearing and welding while the tube mill is running at constant speed. Each one is designed for optimum safety and noise control, ensuring operator safety. Easy installation and minimal maintenance, delivering maximum uptime.

Choose from our wide range of vertical and horizontal free loop, spiral, tower arrangements or mixed solutions.

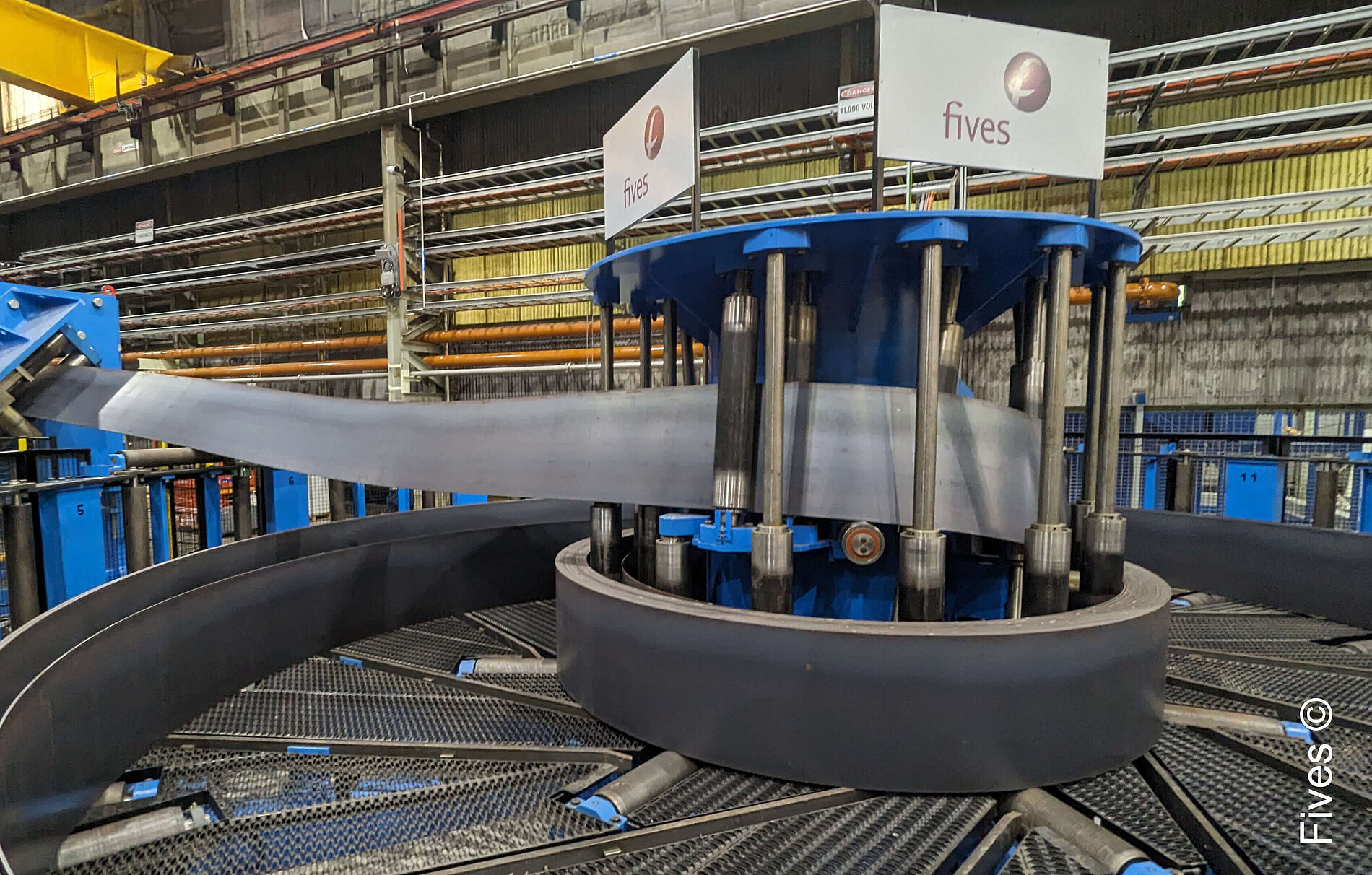

Horizontal Accumulators

free-loop, spiral and mixed solutions

The large storage capacity enables to weld the leading and trailing ends of the coils in a timely manner without stopping the mill. The operations are performed while the mill runs at constant speed.

The strip is accumulated in various arrangements based on how the operation is carried out with constant loops number or in spiral mode. It offers increased capacity compared to the traditional spiral solution.

Vertical Accumulators

Rotating Basket, Free-Loop and Tower

Vertical rotating basket and free loop strip accumulators provide high speed storage to allow end shearing and welding to be carried out while the mill is running at high and constant production speeds. The rotating basket series work with very light gauge strip.

Tower accumulators, specifically designed for stainless steel, include large strips in a vertical configuration without any strip creeping risk.