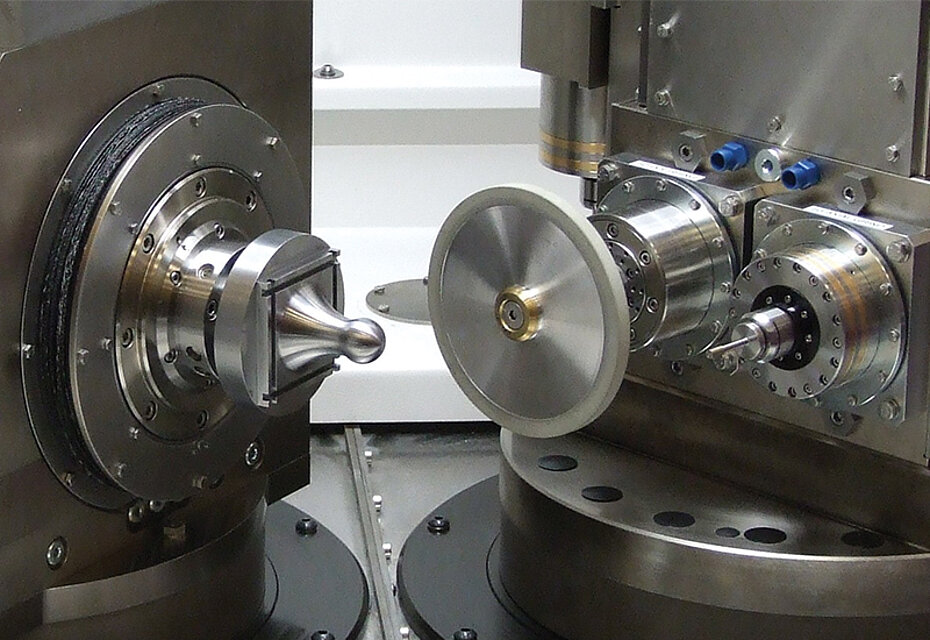

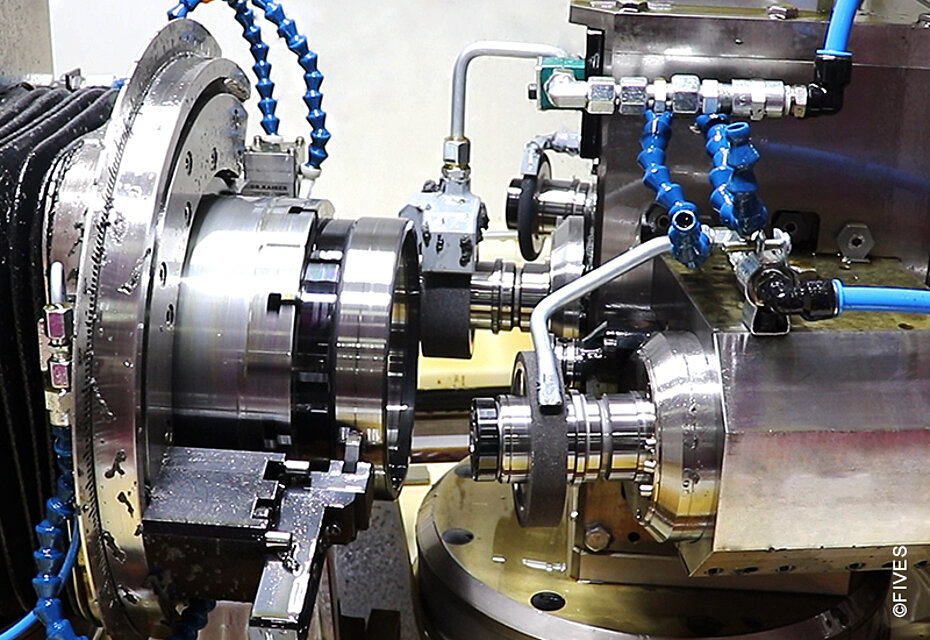

Speed up your manufacturing process and cut operating costs with the Landis TTG 1000, the most flexible grinding machine on the market. This twin-turret, multi-spindle solution combines multiple operations in a compact footprint, enabling you to do more with your production line. Grind ODs, IDs, faces, tapers, raceways, concentric and eccentric diameters to sub-micron tolerances in a single clamping.

truly flexible grinding with the Landis TTG 1000

The flexibility of the Landis TTG 1000 grants you the highest level of control on your production runs. From small batches, to high volume, to multiple products in a production run. Save time on component changeovers and ensure consistently high quality with advanced automation.

In addition, this machine can be engineered to your specific manufacturing and layout requirements. And, like all our Landis machines, you can be assured of the machine’s exceptional stiffness and high thermal stability, thanks to the thermally isolated hydrostatic twin turrets.

Check out our Landis TTG 1000 flyer to learn more.

MACHINE HIGHLIGHTS

In addition to high flexibility, precision and consistency, the Landis TTG 1000 offers:

- High flexibility in workpiece grinding operations

- Various spindle configurations

- Hard turning and polishing capabilities

- Reduced work piece changeover time

- Constant wheel surface speed

- Superior surface finishes

- Easy automation integration

- High performance control with open architecture

OPEN ARCHITECTURE CONTROL

It’s easy to integrate the Landis TTG 1000 into your existing automation. And to get the most out of this advanced machinery, we’ve designed it with open architecture control so that you can reap the benefits of advanced monitoring capabilities, comprehensive sensor integration and ease of programming in a fully-integrated package.

THE ULTIMATE IN FLEXIBLE PRECISION GRINDING

Use up to three different spindles, to complete a diverse array of grinding jobs – both round and out-of-round. With three spindles, you can perform multiple operations on one machine, including ID taper, ID cylindrical, surface, chamfer or radius and OD cylindrical.

With the Landis TTG 1000, high precision is guaranteed thanks to:

- One hydrostatic linear axis with linear motors

- Thermally isolated hydrostatic turrets

- Granite bed

- High performance control

Landis TTG 1000 - Flexible Grinding Solution

The perfect answer to issues faced in the modern manufacturing process, allowing flexible processing, fast changeover, and flexible layouts.

Innovative ID/OD Grinding Solutions

Flexible and innovative grinding solutions for a variety of high-precision ID/OD applications in different industries.

specifications

|

| ||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||