Fives is your single source partner for every machining solution. Leading the industry with innovative machine tool and grinding solutions, Fives is dedicated to its customers’ success, from engineering and operation to service throughout the entire lifecycle of the installation. Fives, high precision machines for a sustainable and digitalized future.

Mark your calendar for September 9-14, and be sure to visit us at the South Hall, Booth 338260. If you haven't already registered, you can secure your spot here.

Together, let's explore how Fives can empower your business with unmatched machining solutions.

Cincinnati Giddings & Lewis Liné Machines Forest-Liné Landis Daisho Giustina

IMTS 2024 SHOWCASE:

CINCINNATI

A world renowned name in machine tools. Now part of Fives, High Precision Machines, Cincinnati is bringing back known legacy brands in new markets.

Vertical Machining Centers

Horizontal Machining Centers

RETROFITS, REBUILDS & RETOOLS

Control Retrofits (PLC & CNC)

When your CNC (computer numerical control) or PLC (programmable logic control) needs an upgrade, ask us about a customized control retrofit solution.

Mechanical Rebuild

Our mechanical rebuild service restores your machine to its original OEM specifications -for optimized productivity and best quality results.

Retooling

Adapt your machine to meet the needs of a production change with our retooling services.

LINÉ MACHINES

New Liné Machines Robotics solution

Machining, Trimming, Drilling, Sanding, Deburring, …Fives is proposing new limits to those application! With its exclusive Liné Machines “like-a-CNC” package and forthcoming high dynamic & accuracy bundle , it never has been so easy to integrate material removal processes using robots into an industrial environment.

Robotics

Milling & Turning

Horizontal Machining Centers

Vertical Machining Centers

Landis 18 for precision shafts including EV drive solutions

In response to customers’ needs for continuing ICE production while simultaneously developing products and manufacturing capability for EVs, Fives has developed the Landis 18 Omega for precision shafts including electric vehicle drive solutions. This cylindrical grinding machine combines many benefits: higher output with lower energy consumption; industry-leading power to size ratio; all with reduced floor space and man-power requirements; plus the lowest Total Cost of Ownership.

Landis TTG 3000 for turning, grinding or polishing

The Landis TTG is a twin-turret, multi-spindle solution to grind ODs, IDs, faces, tapers, concentric and eccentric diameters to sub-micron tolerances in a single clamping. A three-part solution to issues faced in the modern manufacturing process-flexible processing, flexible machine, flexible layouts, it allows for a highly flexible process in which multiple operations may be combined into one machining platform, while maintaining or improving the accuracy and precision of a traditional single spindle machine.

Advanced digital solutions to track machine & process health and optimize machine performance

Fives provides an advanced Digital solution, including a suite of hardware and software solutions tailored to specific needs, with the capability to connect seamlessly and agnostically with any PLC/CNC to gather high-frequency data. Solutions are available from simple dashboards, OEE tracking, Energy monitors and Condition-Based maintenance modules - to track machine and process health; all the way to Predictive Maintenance systems, and fully adaptive machine-learning solutions that automatically optimize machining parameters to improve quality based on auto-detection of the state of the grinding wheel or cutting tool.

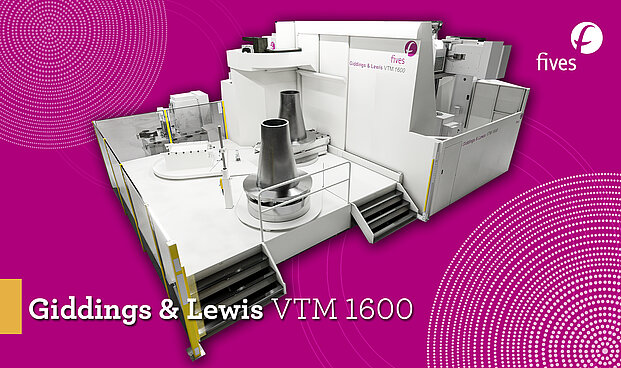

Giddings & Lewis VTM 1600 Dual Machining Center

One of the most recognized names in machine tools for over 100 years. The Giddings & Lewis VTM 1600 Dual Machining Center is one of the latest technologies developed for a customer in the space industry. Manufacture large complex components for lower cost and significantly faster cycle times.

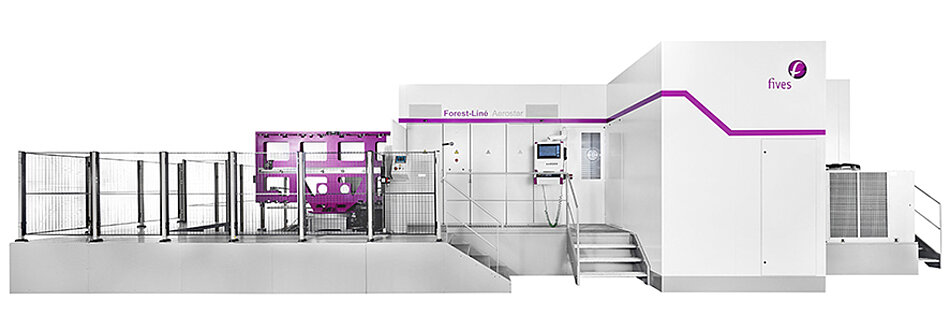

Mirror Milling Star

Mirror Milling Star is the digital machining solution for high-speed milling, drilling and trimming of 3D aluminum or composite fuselage panels. Thanks to its surface scanning system, the machining adapts to the real shape of the panel and the dual 6-axis heads arranged in a mirror guarantee an unequaled level of precision by controlling the symmetry and the thickness of the pocket depth bottoms, whatever be their complexity and diversity.

RELIABILITY & PRODUCTIVITY

Parts, service, and aftermarket for your machine tools. Providing comprehensive life-cycle support and factory expertise for maximum equipment availability and utilization at a reduced cost.