When you are working with large, complex components, you need a milling machine that you know will deliver highly accurate and repeatable results. With more than 100 years’ experience in mill turn technologies, we have developed a range of versatile, high speed cutting solutions that prioritize stiffness, precision and reliability.

With flexibility an integral part of our design, our sturdy machines are engineered to adapt to different types of machining processes and materials. We support your individual mill turn process requirements by providing a complete manufacturing solution, from loading and unloading, to cutting specifics, to robotized assistance.

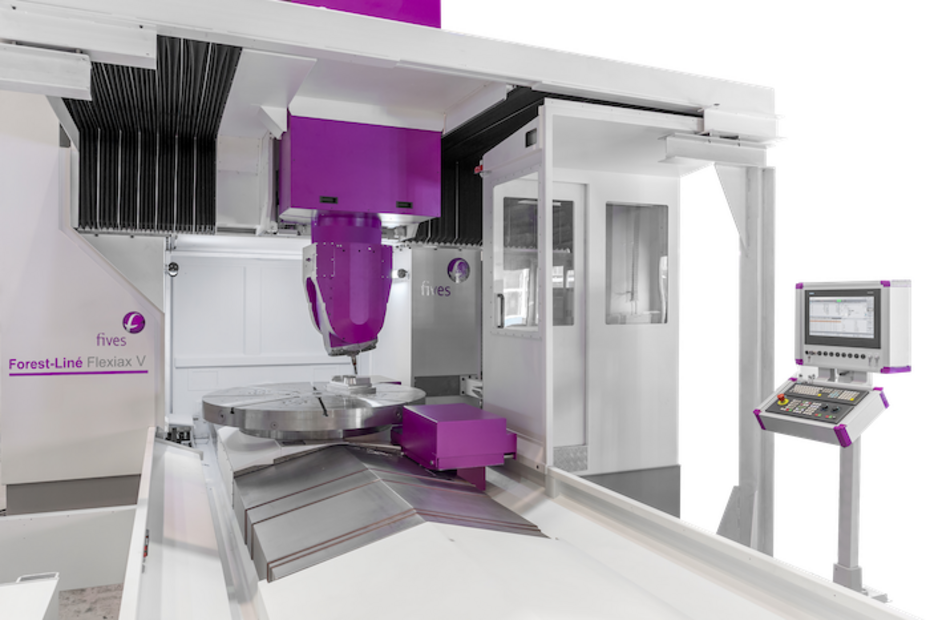

Forest-Liné Flexiax V

Precision, productivity and flexibility

The Forest-Liné Flexiax V is designed for high precision, fast production and impressive versatility.

Engineered to ensure exceptional stiffness and stability, this high-speed mill turn machine delivers the highest possible throughput, while guaranteeing a very high degree of accuracy, every time.

The Forest-Liné Flexiax V has the ability to switch between milling, trimming and drilling functions. The constant overhang ram is specifically engineered to deliver the rigidity and accuracy needed for hard materials machining.

Aeroengine | Aerospace | Agriculture, Construction & Mining | Defense

The Forest-Liné Flexiax V is ideal for a variety of applications and materials:

- Aircraft structures

- Hard metals

Forest-Liné Modumill MT

Innovative roughing and finishing of hard metals

The Forest-Liné Modumill MT is designed in a vertical configuration for optimized roughing and finishing of complex parts made from titanium and other hard materials.

Available with either a single or double ram, this 5-axis profiler offers highly flexible solutions for circular components, using both milling and turning operations.

The patented constant overhang of the Forest-Liné Modumill MT ensures the highest possible accuracy, in every position. High stiffness also enables high torque processing with a high-speed spindle, as well as high pressure and fast flowrate coolant processing.

Aeroengine | Aerospace | Agriculture, Construction & Mining | Defense

The Forest-Liné Modumill MT offers maximum flexibility in the smallest possible footprint.

- Innovative, eco design

- CNC: SIEMENS 840D sl or HEIDENHAIN iTNC

- User-friendly integrated HMI: FL Vision

- Direct measuring system

- C-axis integrated into the ram

- Multiple industries served

Liné Machines mill turn

Flexible gantry mills for milling and turning

All of our Mabormill, Promill or Vertamill gantry mills are fitted with a rotary table to offer a vertical mill turn solution.

The rotary table can be positioned to combine milling and turning operations.

The exclusive HS5 head combines a milling spindle and a turning tool holder to ensure high productivity and improved cycle time as you can switch from turning to milling operations without changing the head. In milling mode, it allows 105 kW, 10,000 rpm and 1,000 Nm.

When multiple attachments, effectors or heads are required, automatic changers can store them in a specific area of the machine.

Aeroengine | Aerospace | Agriculture, Construction & Mining | Defense | Energy

- The optimized hydrostatic support of the table ensures sustainable performance and the high-precision measuring systems provide accurate positioning

- The rotary table can range in size from 2 to 8 meters

- High-precision measuring systems provide accurate positioning