Productivity enhancement solutions enable you to keep with the evolving demands placed on your machine-tools. As a minimum, you want to avoid performance degradation over time. But you might need to completely change the type and size of parts being machined. This is where our productivity enhancement solutions come in.

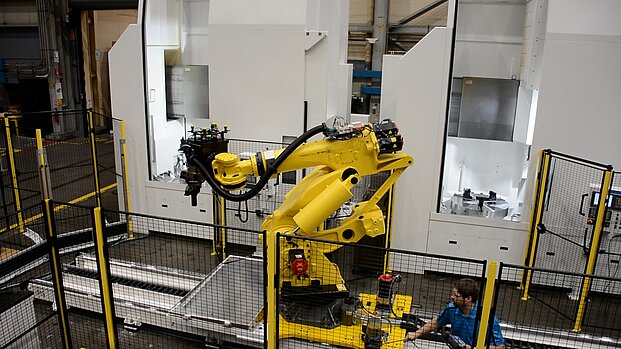

Automation

Smart automation retrofits not only enhance productivity, but improve part quality and safety too. Our state-of-the-art, fully-integrated robotics and cell automation solutions are designed to meet the needs of your assembly line. So you can be sure operational excellence is your everyday standard.

OEM Engineering Modifications

Bring older machines back to original specifications - or better - with our productivity-enhancing engineering solutions. From downtime-busting maintenance programs to complete rebuilds of critical components, we have the know-how to enhance your machine-tool performance.

Remanufacturing

Take advantage of the latest developments to boost your productivity with remanufacturing services. Incorporating full rewiring and control system upgrade, our customized proposals will increase feed rates and machining speeds. With dramatic results for your bottom line.

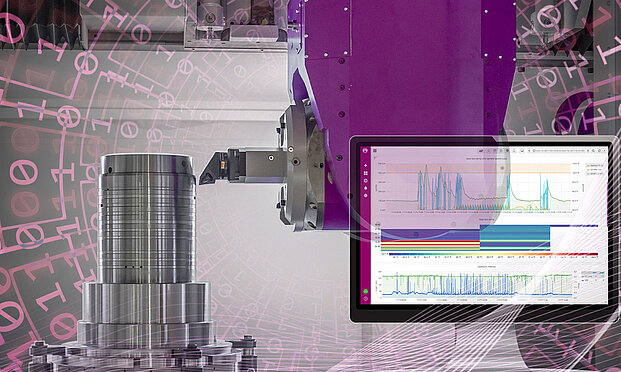

Industry 4.0

In a world of unparalleled data connectivity, work smarter with our Industry 4.0 process digitalisation solutions. Delivered via our CortX Alchemy platform, we provide actionable, real-time insights that support improved decision-making and optimize your machine performance.

Process cycle time optimization

Our advanced cycle time optimization solutions enhance productivity and increase profitability. AI algorithms continuously refine your process to ensure you operate at maximum capacity to achieve lowest cost per piece. All without compromising on quality.

Retooling / Production changes

Update your machine-tools to your business needs with our retooling services. We can adapt existing machines to new machining requirements by increasing bed dimensions or changing the available tooling. We can also re-engineer the complete machine for a cost-effective alternative to machine replacement.