You must cope with extreme Gen3 AHSS annealing cycles, challenging high alloyed steel coatings or specific process parameters to reach exposed surface quality products. We have the expertise and technologies to help you succeed in the demanding automotive steel market and to put you ahead of the competition.

Achieving success

Meeting the challenges of AHSS & UHSS

Advanced and ultra high-strength steels - characterized by their very high tensile strength and high elongation - must adapt to automotive design and reduced emissions, while maintaining the strength required to keep drivers and passengers safe.

With numerous annealing and galvanizing line references in the last decades, we have the know-how and the technology to enable you to meet your production goals, reach new markets and exceed your customers’ expectations.

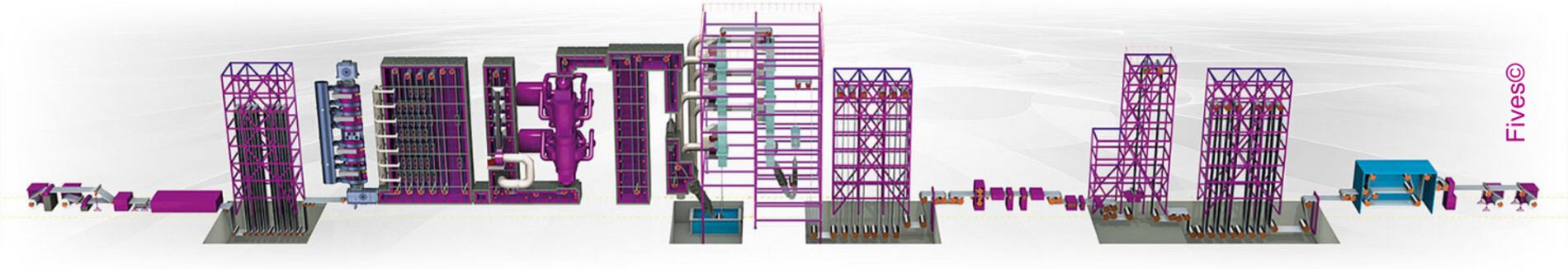

RECORD PERFORMANCES

Capacity 1,100,000 tpy | Strip width 2,100 mm | Strength 2,000 MPa |

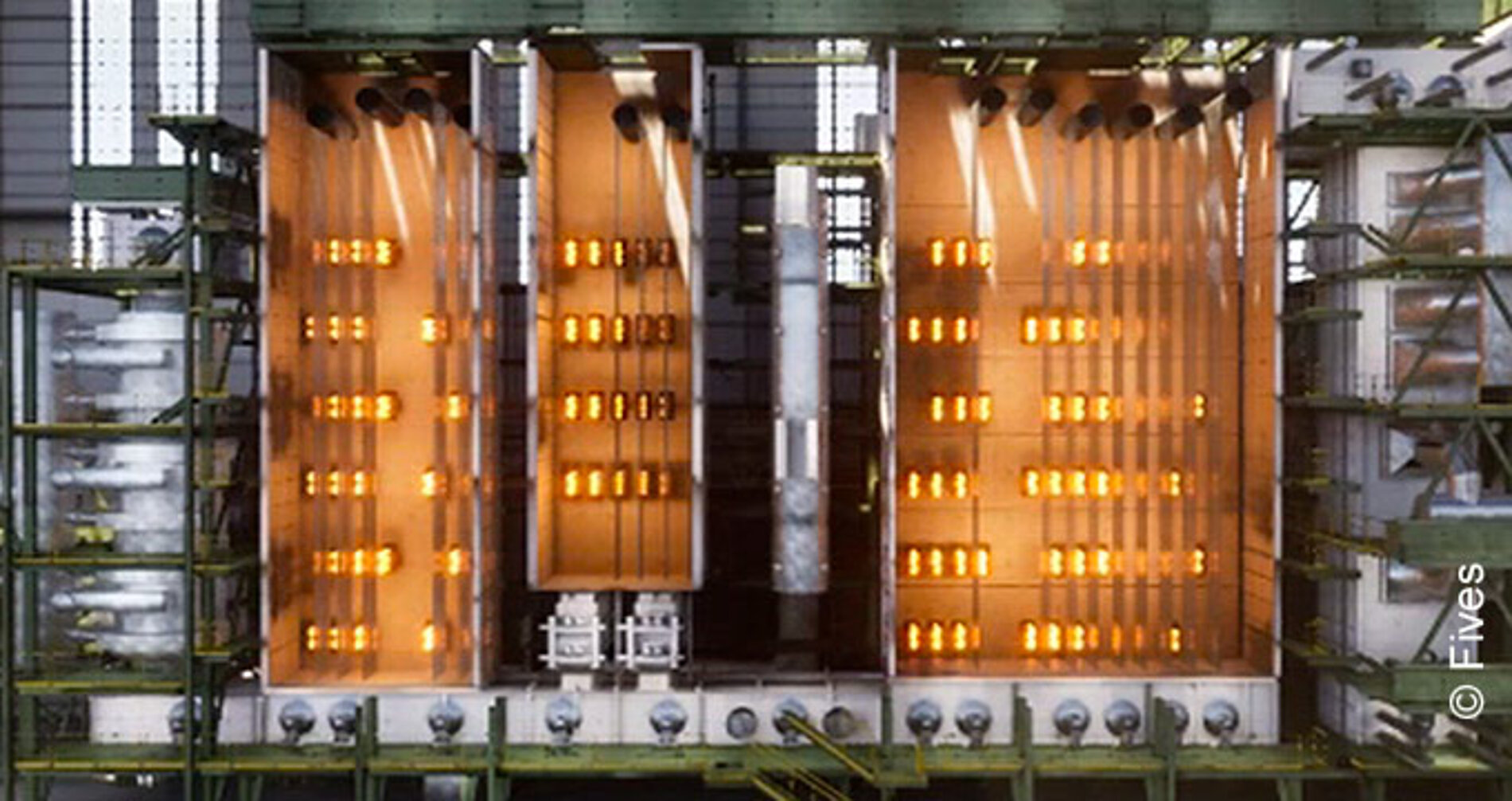

DIRECT FIRED FURNACE

- Flameless combustion heating

- Non-oxidizing operation

- Accurate pre-oxidizing control

- Ultra-low NOx

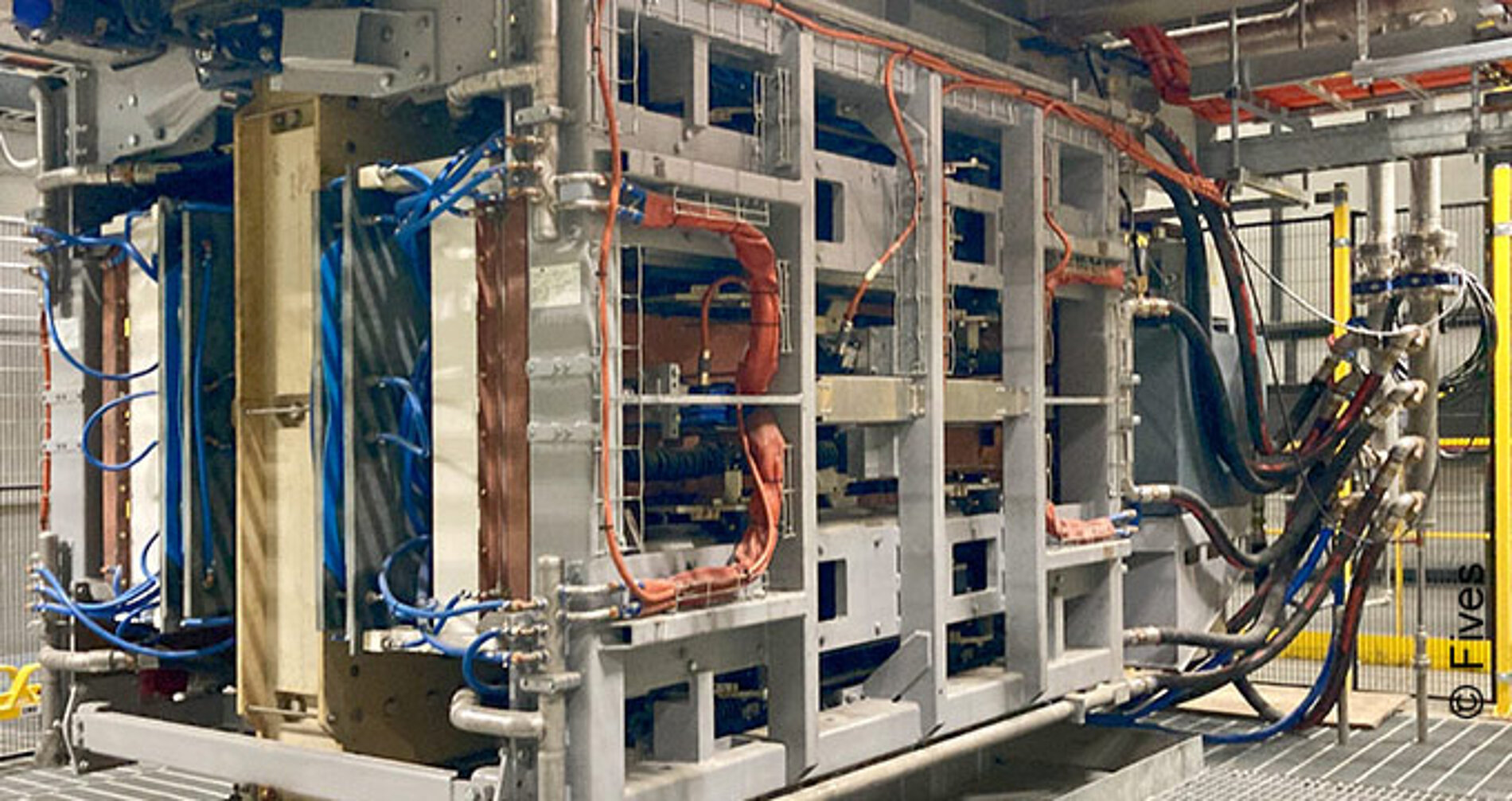

INDUCTION HEATING

- EcoTransFlux™, high-power induction

- Heating capability: up to 1,200°C

- High heating rates: up to 400°C/sec

- Excellent heating efficiency for AHSS/UHSS

ULTRA-RAPID COOLING

- Revolutionary non-oxidizing wet cooling

- Cooling rate 1,000°C/s without pickling

- Extend CGL capability for Gen3 AHSS

- Annealing & galvanizing in same line