Skin-pass mills from Fives are designed to give you the finish you want, either as part of your NeoKoil® strip processing line or as a standalone equipment for perfect finish quality.

YOUR desired surface quality

Our skin-pass mills are designed using finite element modeling to ensure simplicity and optimum performance.

- Desired surface finish, whether that’s rugosity or brightness

- Suppressed yield point elongation, enabling the steel to be formed without developing faults

- Improved strip flatness

A range of skin-pass mills is available for any type of applications for annealed and galvanized steel products, as well as stainless steel. These skin-pass mills are also available in a tandem version for double reduction for tin plate products.

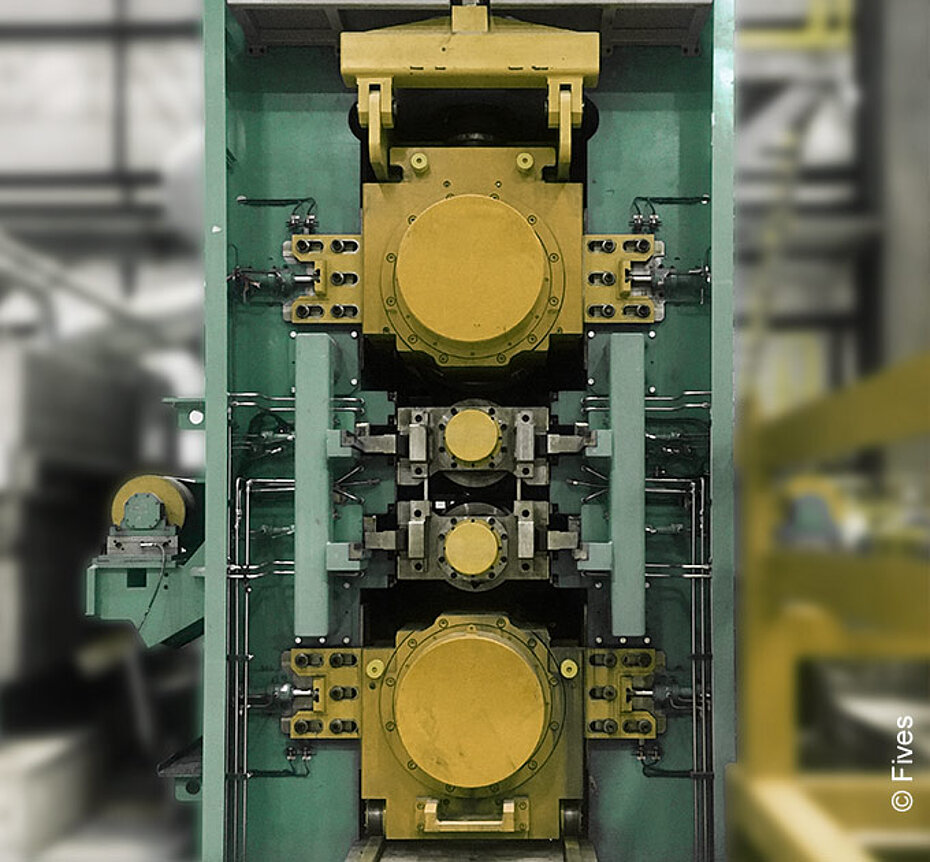

4Hi skin-pass mill

Novel design features

- Designed for a variety of steel grades from very low to very high strength

- Used on continuous annealing and galvanizing lines, and can be coupled with a tension leveller

- Up to 1,880mm wide and speeds up to 1,000 m/min

- Detergent capture and filtering to minimize environment impact

6Hi skin-pass mill

Flexible flatness

- Applicable in continuous annealing lines to futher improve flatness without a tension leveler

- With two additional intermediate rolls, it can gurantee better flatness under any operating conditions

- It is equipped with a intermediate roll shifting system to enhance operational flexibility on bending

2Hi skin-pass mill for stainless steel

- Designed to provide the high degree of cleanliness required for stainless steel

- High-performing roll polishing system to achieve a very bright strip surface

- Double acting roll force cylinder for efficient and accurate roll control

- Designed to provide easy access to all parts of the machine for safe and simple operation and maintenance