AdvanTek® combustion system gives you absolute control - from capacity, to flame length and fuel choice - resulting in high combustion efficiency with ultra-low NOx emissions for your preheating and annealing operations.

empower production goals

We use computational fluid dynamics simulations, tests in our R&D facilities and actual operation in industrial furnaces to ensure optimum combustion efficiency using various types of fuels. AdvanTek® combustion systems are integrated in all Fives’ new furnaces and revamping projects, with more than 6,000 AdvanTek® burners entering operations in the last 12 years.

Our multi-discipline expertise in combustion, thermal modeling, construction and control engineering enables us to help you:

- Increase energy efficiency

- Achieve optimal operational performance

- Level up competitiveness and production quality

- Reduce emissions

- Improve safety

In addition, our AdvanTek® combustion system benefits from the advanced capabilities of our Virtuo thermal optimization software, which enables fully automatic, data-driven furnace operation for optimum performance.

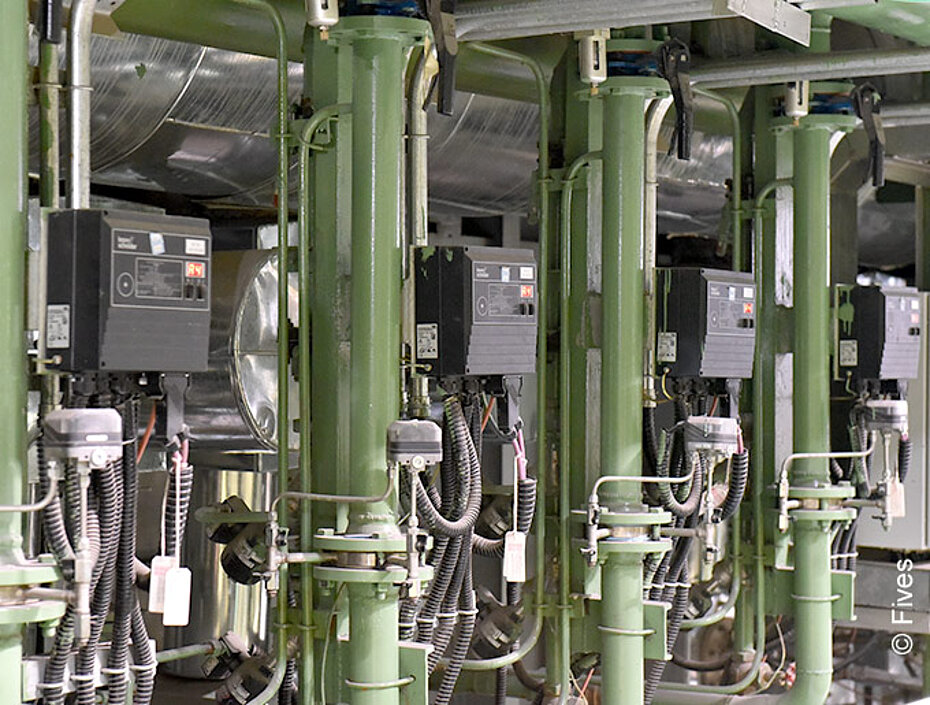

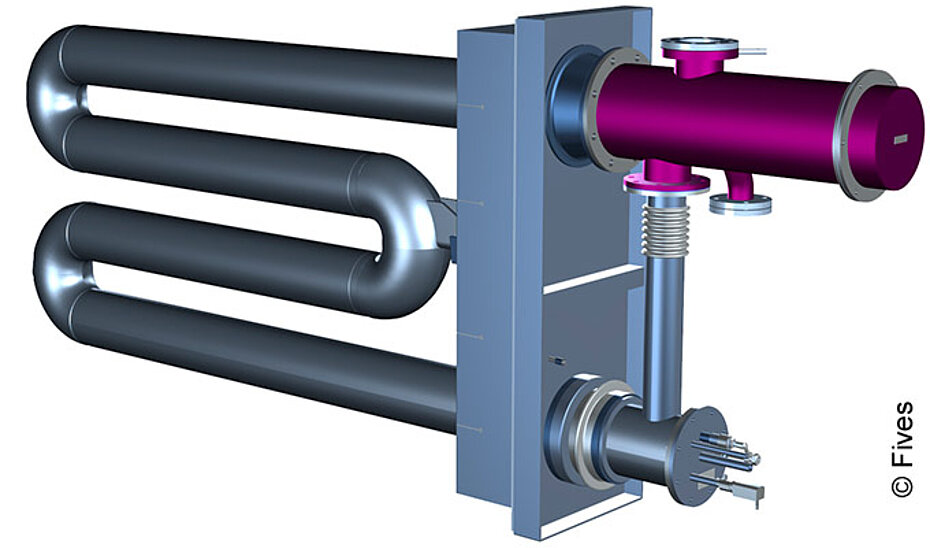

Radiant tube burners

AdvanTek® radiant tube burners (WRT and URT) are the Best Available Technology in terms of burner capacity, reliability, consumption ratio and emissions.

Benefits:

- Reduced consumption thanks to highly efficient recuperative burners

- Ultra-low NOx emissions

- Fuel flexibility: NG, COG, MG, etc

- Smart digital control to maximize flexibility and efficiency

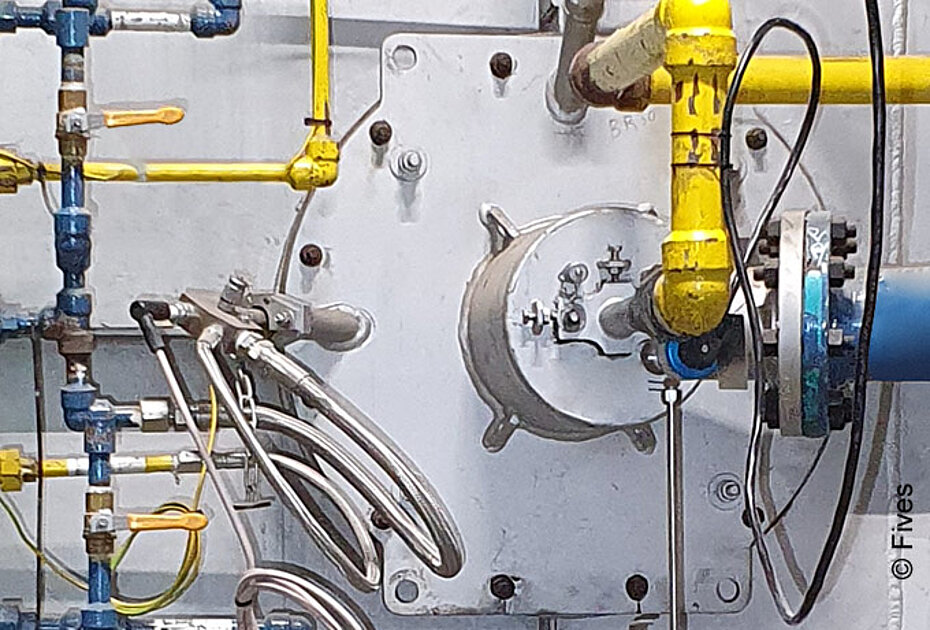

Direct fired flame burners

An essential component of the preheating section, these burners work to ensure strip cleanliness, accurate furnace O2 level control and strip temperature uniformity.

Benefits:

- Significant reduction in CAPEX and OPEX

- Improved homogeneity thanks to flameless mode

- Better surface quality due to precise temperature & oxidation control

- Ultra-low NOx emissions