Offering custom-built machines to suit any requirement and provide straightening solutions for any material composition and size, Bronx machines provide high standards of straightness, surface finish and controlled surface hardness.

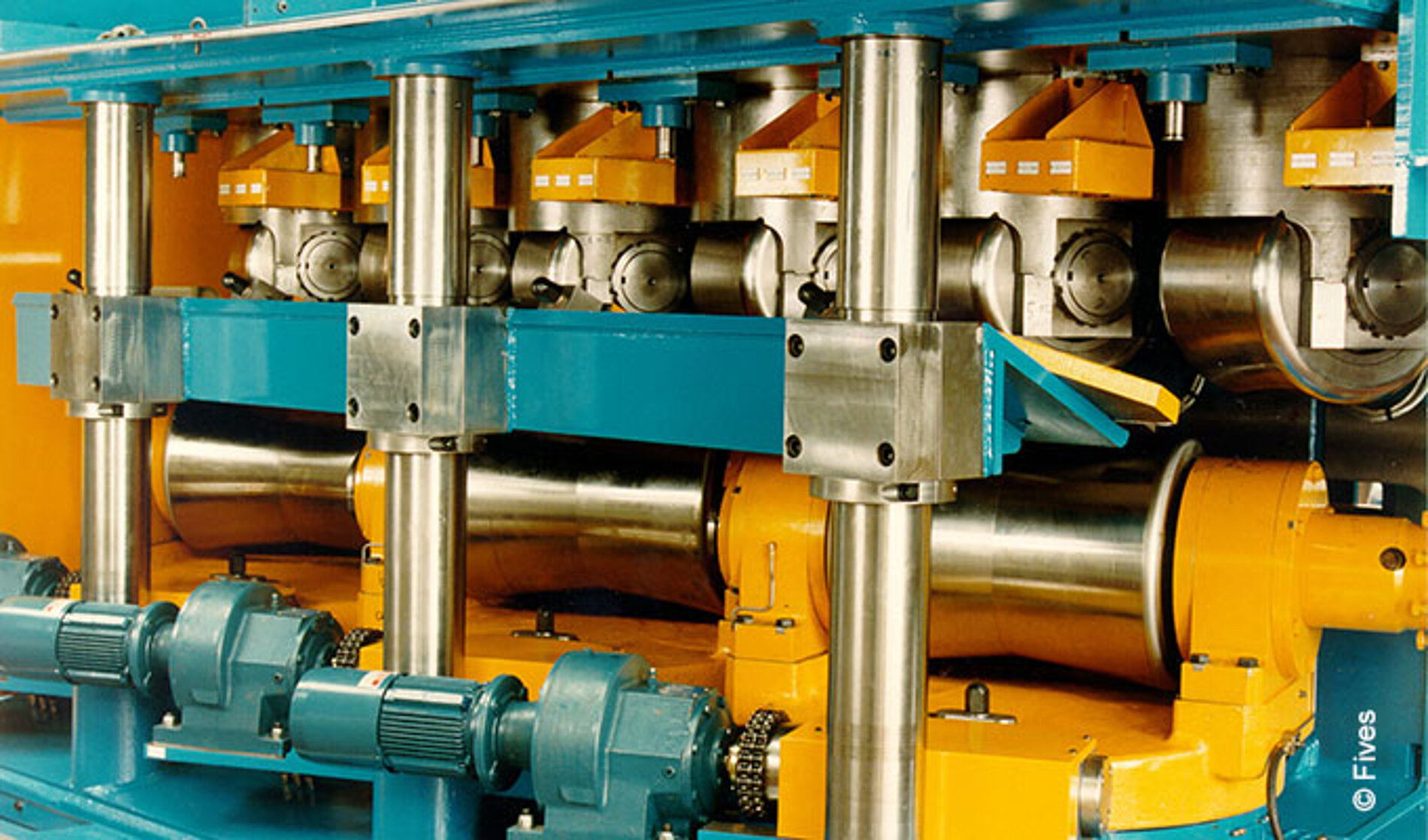

Tube Straighteners

Designed for a range of tubular products, Bronx straighteners can sustain the loads associated with the straightening of thick or thin walls and welded or seamless plain or upset tube & pipe at high speeds.

Bronx machines can handle tubes with a diameter from 1 mm to 660 mm and thickness of 0.2 mm to 60 mm.

Bronx straighteners offer an excellent production rate, longer equipment lifespan and improved accuracy without surface blemishes.

Bronx machines give full satisfaction meeting our requirements in terms of operating performances and straightening quality. An excellent engineering work to manage the integration of straighteners into our existing lines,” says Jean-Christophe Chassaigne, President & Managing Director of Salzgitter Mannesmann Stainless Tubes, France.

Long Product Straightening Machines

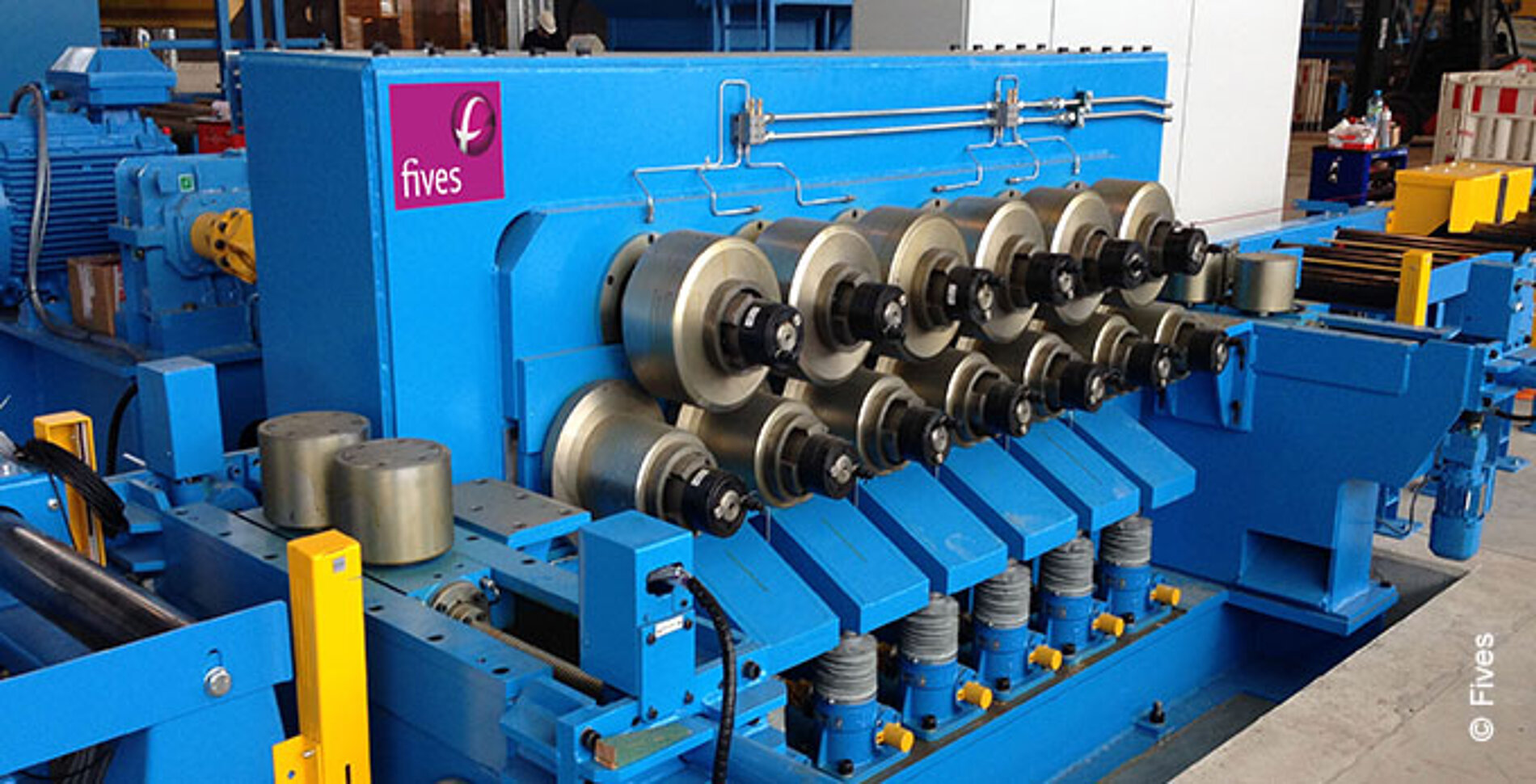

Bar Straightener

Bronx bar straighteners cover a range of 1.5 mm – 300 mm in diameter and hold high production speeds of up to 180 mpm.

- Two-roll straightener

- Multi-roll straightener

- Two-roll "smart machine" straightener

section STRAIGHTENER

Bronx section straighteners are designed for any types. Production speed can reach 240 mpm.

- Fixed-centre section straighteners

- Variable-centre section straighteners

- Two-plane section straighteners

- Between housing section straighteners

rail Straightener

Bronx rail straighteners are designed with a horizontal-axis straightening machine and a vertical-axis straightening machine.

They partner with the necessary electrical and hydraulic equipment to ensure excellent product straightness.