The AdvanTek® combustion system gives optimum combustion control, from capacity to flame length to fuel choice, and the lowest NOx emissions. It is the result of more than 40 years of improvements to our combustion technology.

Fives recently developed a new reheating burner that can inject a blend of hydrogen and natural gas in a range from 0% to 100% hydrogen. Read more.

AdvanTek® burners at a glance

Our proprietary AdvanTek® combustion system for Stein Digit@l Furnace® features the following advantages:

- Capacity range: up to 6 MW

- Air combustion temperature: up to 650 °C

- Ultra-low NOx emissions

- Fuel flexible: NG, COG, FO, LPG, MG, H2

- Compliance with European and ISO standards

- Fully automatic control

ADVANTEK® CWF & MWF

Central Wide Flame (CWF) and Modulating Wide Flame (MWF) burners

ADVANTAGES:

- Capacity range: 1 - 5.5 MW

- Multi-fuel capability, including hydrogen

- High operational flexibility

- Digital mode (on-off firing) and proportional mode

- Low NOx emissions: < 40 ppm

- Reduced energy consumption

ADVANTEK® WFB & WFMB

Wide Flame Burners (WFB) and Wide Flame Modulating Burners (WFMB)

ADVANTAGES:

- Lateral side burners

- Uniform heat distribution

- Reduced NOx emissions

- Optimized furnace operation

- Located on side walls, top and/or bottom of the reheating furnace

ADVANTEK® BLF & BMF

Long Flame Burners (BLF) and Modulating Flame Burners (BMF)

ADVANTAGES:

- Capacity range: up to 6 MW

- Air temperature: up to 650 °C

- Optimum heat distribution

- Located at the side wall or on front side

ADVANTEK® BFP

Flameless Radiant Roof Firing Burners (BFP)

ADVANTAGES:

- Capacity range: up to 2 MW

- Roof temperature: up to 1 450 °C

- Flat flame outside the burner tunnel, perpendicular to the burner axis

- New generation hydrogen burners with reduced NOx emissions < 50 ppm

ADVANTEK® lancing

Oxygen-enriched lancing technology

ADVANTAGES:

- Optimized flameless combustion

- Enhanced thermal performance

- Reduced gas consumption

- Low NOx emissions

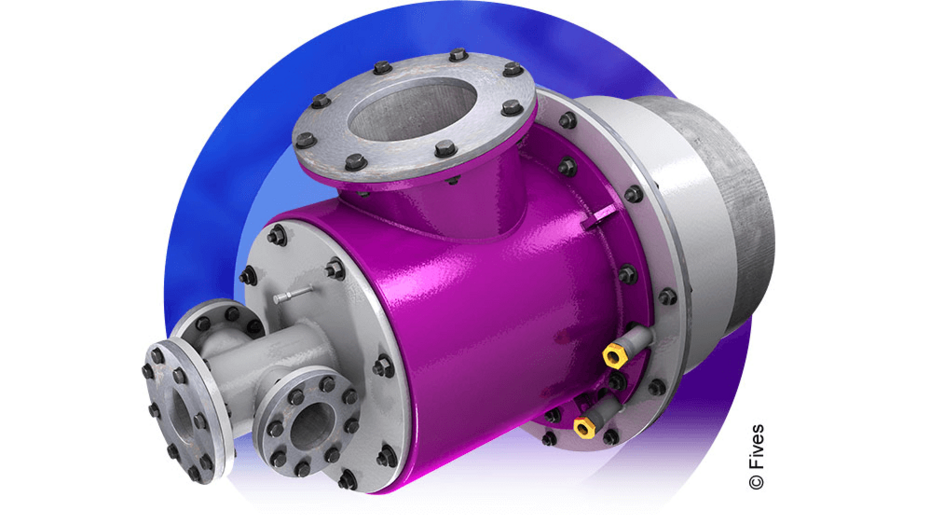

ADVANTEK® REGEN

Regenerative burners

ADVANTAGES:

- Four sizes available, ranging from 1 500 to 2 250 Nm3/h of BFG that can be combined based on 500/950 ̊C air/BFG temperature

- Uniform furnace temperature thanks to contracting and expanding nozzles

- Patented diffuser design

- Full on-off mode operation

- Available with or without pilot burner

- Easy maintenance