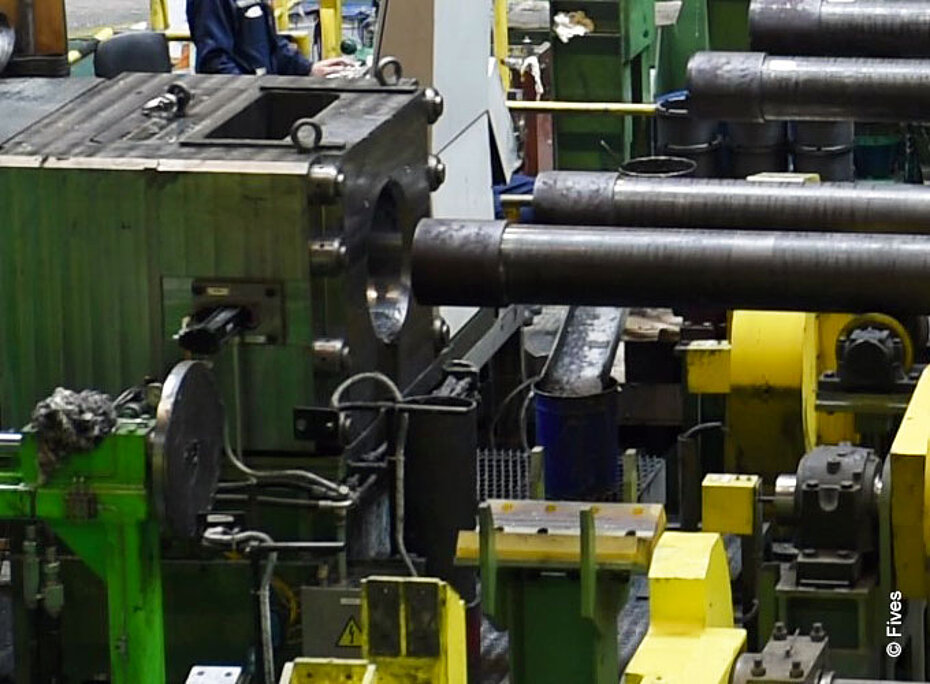

Being at the forefront of hydrostatic pipe testing machinery for more than 110 years, we thrive to meet the needs of customers through reliability, flexibility and safety. Our hydrostatic testers safely deliver very fast and accurate test pressure build times.

HYDROSTATIC PIPE TESTERS

Fives offers Taylor-Wilson hydrostatic pipe testers to accommodate any length variation, as well as tube and pipe testing with diameters from less than 25 mm to over 660 mm (1 to 26 inches):

- Flexible: different end conditions and pipe lengths

- Automatic pipe length, grade and pressure settings

- Increased efficiency and safety

Tests are performed with stable pressure of 35 bars (500 psi) to over 1,750 bars (25,000 psi), and can be easily varied to specific standards.

Fast and accurate Hydrostatic Testing

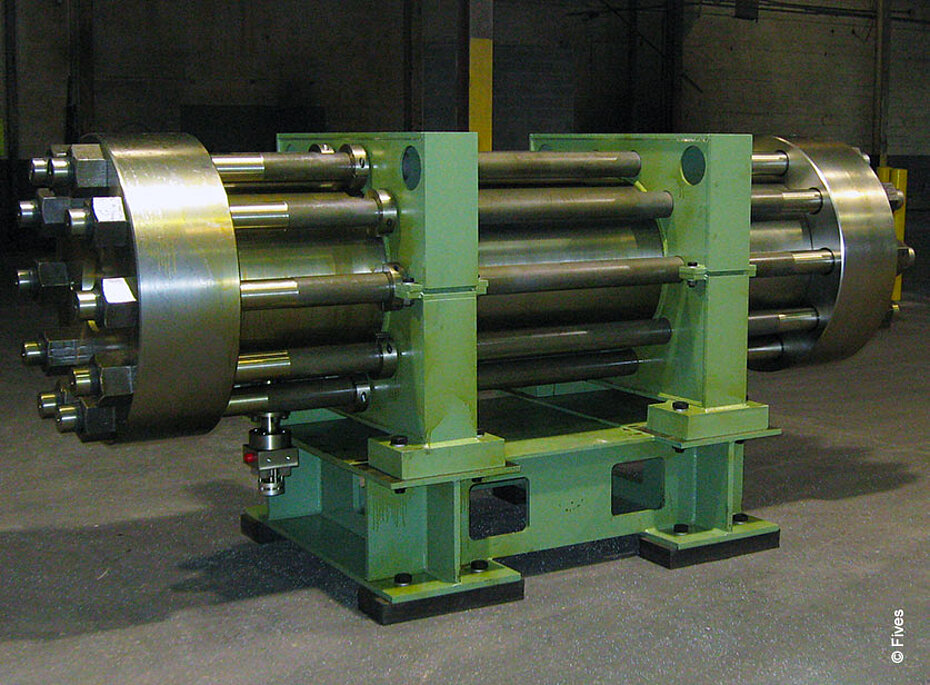

- Quick change technology: drop-in quick tooling change available

- Specially designed intensifiers for greater stability during test-hold periods

- Ability to transmit data through PLC control and network to other areas of the finishing floor

- Multiple sealing device options

- Designs that can accommodate plain end square cuts, API line pipe ends, threaded and coupled ends, mill sawed ends or pierced ends

Leak

Testers

- Rotary transfer handling unit

- Interchangeable tooling for ID and OD seals

- High pressure single stage intensifier

Collapse

Testers

- Lab style testers:

- Simple static vessel

- In-line production testers:

- No cutting of samples or yield loss