Process Burners

Customized process burner solutions for refineries and petrochemical furnaces

Process burners are a vital component of refineries and petrochemical plants, providing energy through combustion to fired heaters and furnaces. Fives designs and supplies custom low-NOx burners for any application, technical requirement or project specification. Our experts oversee the entire process, from engineering design, to site assistance, revamping and training.

CFD modeling to deliver maximum efficiency

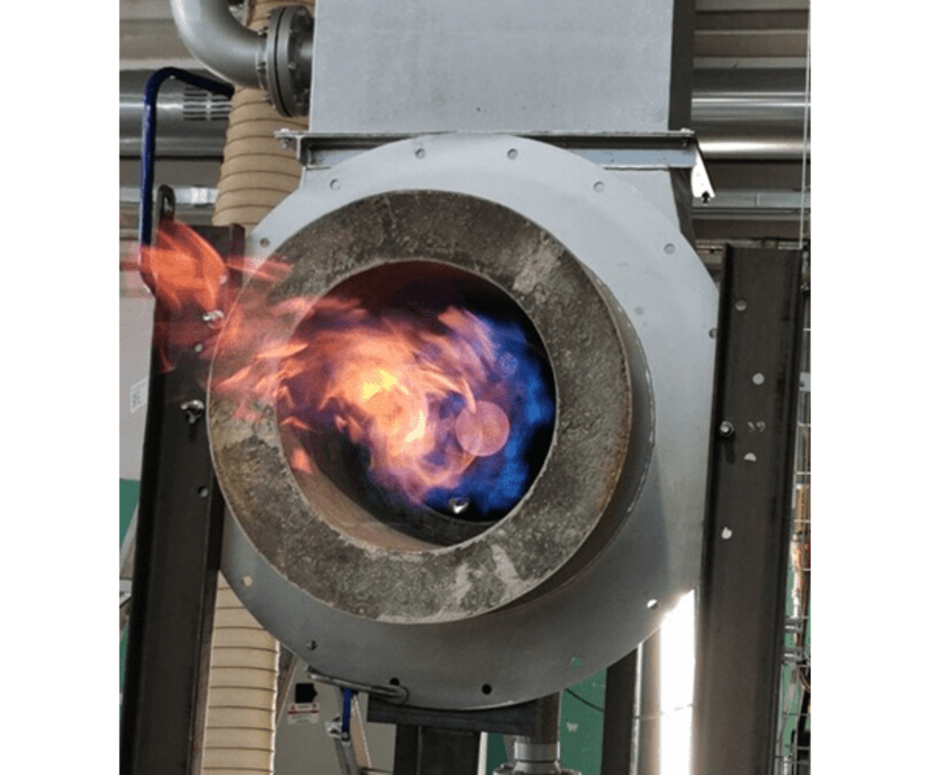

At Fives, we continually upgrade our process burner efficiency through a combination of computational fluid dynamics (CFD) modelling and in-house, real-scale firing tests. We offer a full range of accessories designed to minimize maintenance and the need for spare parts.

Our experts can completely retrofit existing plants or design new installations in compliance with local regulations. Our customizable solutions include:

-

ITAS process burners: Ideal for diverse refining and petrochemical applications including crude distillation units, vacuum distillation units, delayed coking, grey and blue hydrogen production, and ethylene cracking

-

ITAS Intensityflame: A dual-fuel burner suited to direct-fired hot gas generators and indirect-fired air heater applications; equipped with industrial conical corner burners for greater combustion and a short, highly stable flame

Advanced low-NOx, dual-fuel burner technology

Fives is a global champion of low-NOx combustion. Our burners are highly efficient and suitable for a variety of applications.

Our North American Magna-Flame™ low-NOx industrial burners are commonly used in boilers, air heaters, incinerators, process heaters, dryers and calciners. This advanced burner line is fully customizable to clients’ unique process requirements, combusting a variety of gaseous and liquid fuels.

The North American Fire-All™ product family suits a broad range of thermal applications from air heating to forging. These nozzle-mix burners can fire gaseous fuels, light or heavy oil, or dual fuels. Its dual-fuel capability facilitates furnace temperatures up to 1,315°C (2,400°F).

High-performance, ultra-low NOx burner solutions

Our experts work closely with clients to minimize their environmental impact and ensure that their plants satisfy all local, federal and international emissions requirements.

Our low-NOx and ultra-low NOx burners deliver impressive emissions reductions for petrochemical heater applications:

-

Pillard LONOxFLAM® AS: Ensure the lowest NOx emissions when firing liquid and gaseous fuel oil, thanks to air-staging technology

-

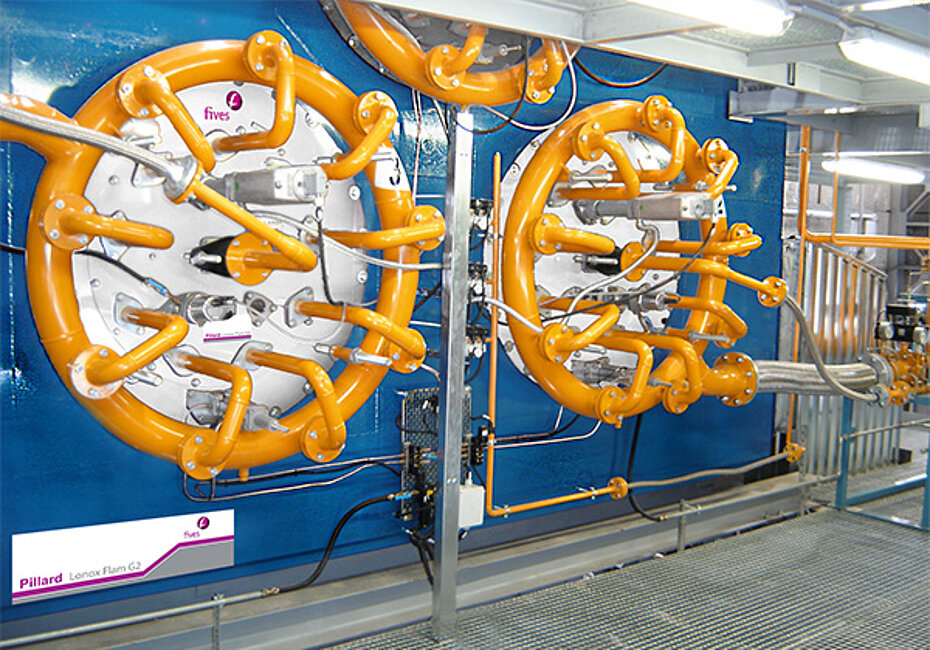

Pillard LONOxFLAM® G2: Enable 50-75% NOx reductions with internal flue gas recirculation (FGR)

-

Pillard GRFLAMTM ND: Achieve low-NOx emissions with this natural draft burner

Product Finder

Find the combustion solution that fits your needs

Browse and download our related product literature