Pulp & Paper

Combustion technology delivers sustainable paper production for the future

Fives helps pulp and paper producers maximize high-quality product delivery while lowering costs. Our innovative combustion technology helps producers achieve a truly sustainable production process.

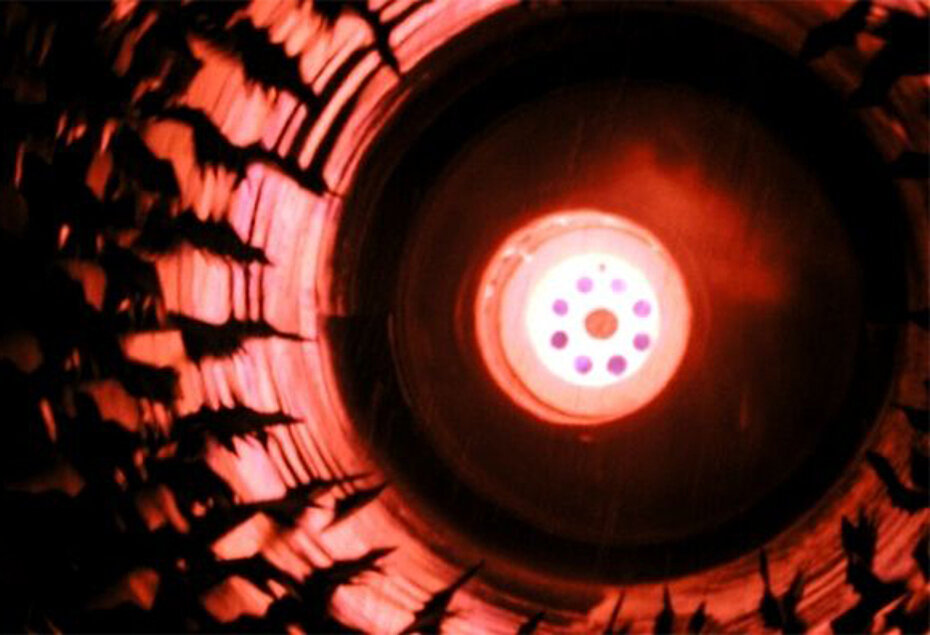

Advanced industrial combustion solutions for tissue paper production

Tissue paper production is a delicate process, and producers need reliable burners to ensure high quality. Fives is continuously innovating to improve our combustion systems and maximize client uptime and production rates.

We apply low-NOx technology to reduce emissions without sacrificing thermal efficiency or temperature uniformity. Our experts can help you customize the perfect induct or corner fire systems to heat air for Yankee hood dryers or thru-air dryers:

- Benefit from cutting-edge emissions-reduction technology with the new North American ultra-low NOx EcoFornax LExTM

- Leverage compact design and a high turndown ratio with ITAS Intensityflame conical corner burners

- For drying applications that use variable amounts of air, we offer the ITAS Ductflame H/T/C

- For complete control over recirculation flow, use the ITAS Ductflame R

Fives also designs custom hot gas generator systems to meet all your production specifications.

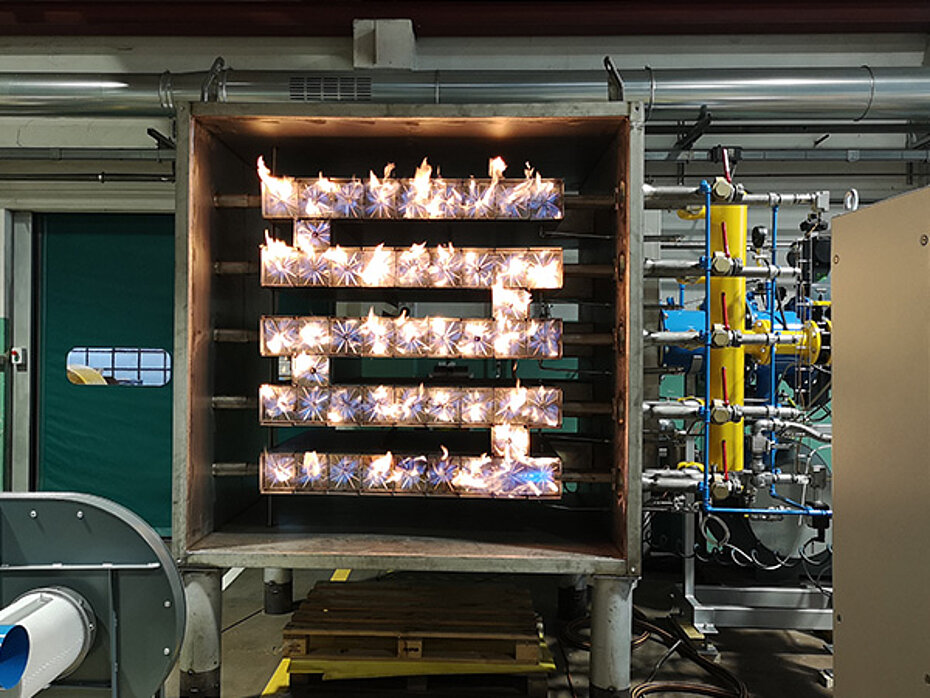

Temperature uniformity for non-woven paper production

Non-woven paper is produced using thru-air dryers, which can be powered by our range of standard, low-NOx and Ultra-low NOx burners. In the pulp & paper industry, the quality of the drying medium directly influences the quality of the product. Fives performs computerized fluid dynamics (CFD) modeling to improve your installation’s temperature uniformity.

Fives can provide design services, analysis, remote or onsite monitoring, and training for any paper producers using our cutting-edge equipment. Our solutions for thru-air dryers include:

Tailored combustion solutions for board, coated paper and newspaper

Producing board, coated paper and newspaper requires a process called impingement drying. Fives has developed numerous innovations aimed at reducing costs for pulp and paper producers.

Hot air heaters, which burn fuel to generate a hot gas flow, are major contributors to production costs. The ITAS Ductflame H/T/C and ITAS Ductflame R and ITAS Intensityflame burners for hot air heater applications are offered at various price points to meet clients’ specific needs.

Our Ultra-low NOx Pillard HeatGen System™ equipped with the Pillard NANOxFLAM® Compact burner is a premium solution for hot air drying. It comes pre-wired and tested for immediate use.

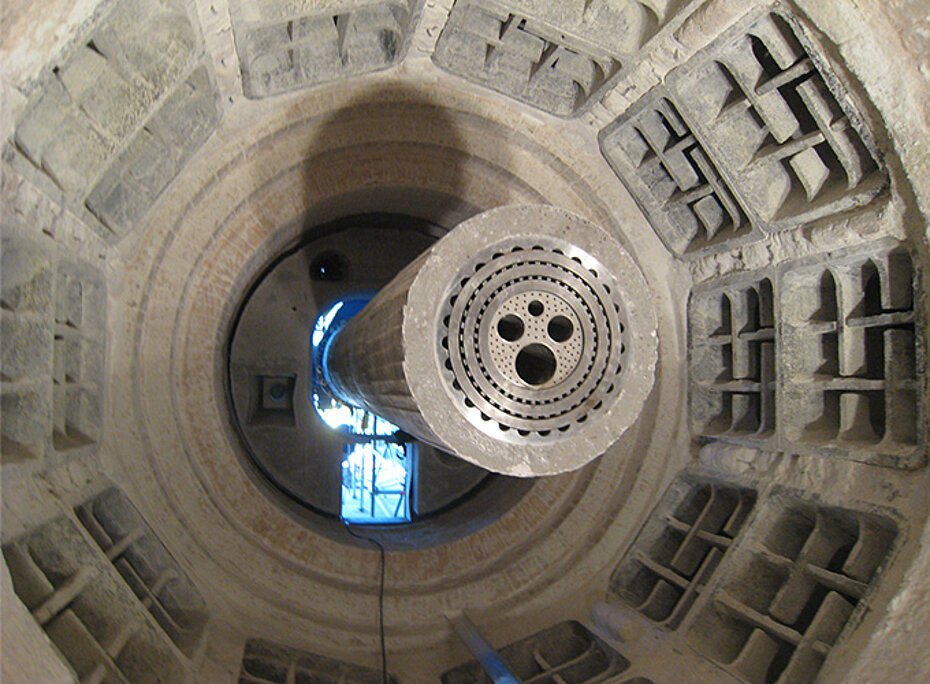

Powering the Kraft process for pulp production

The Kraft process is a vital step in the production of paper, in which chemicals are recovered and reused to manufacture pulp. Our burners can help you reach your target cost, emissions and quality.

The Pillard ROTAFLAM® burner powers lime recovery rotary kilns. This industry-leading technology offers users a wide range of flame-shaping options and improved thermal efficiency, without sacrificing high flame stability.

For steam boilers, Fives offers the Pillard LONOxFLAM® G2 and the Pillard NANOxFLAM® burners. These burners offer lower NOx emissions, and both are registered as Best Available Technology (BET).

Fives can also power black liquor recovery boilers, which carry out a vital step in the Kraft process. The Pillard STARTFLAMTM burner helps start other burners, and can warm up the necessary equipment to complete this delicate process.

Product Finder

Find the combustion solution that fits your needs

Browse and download our related product literature