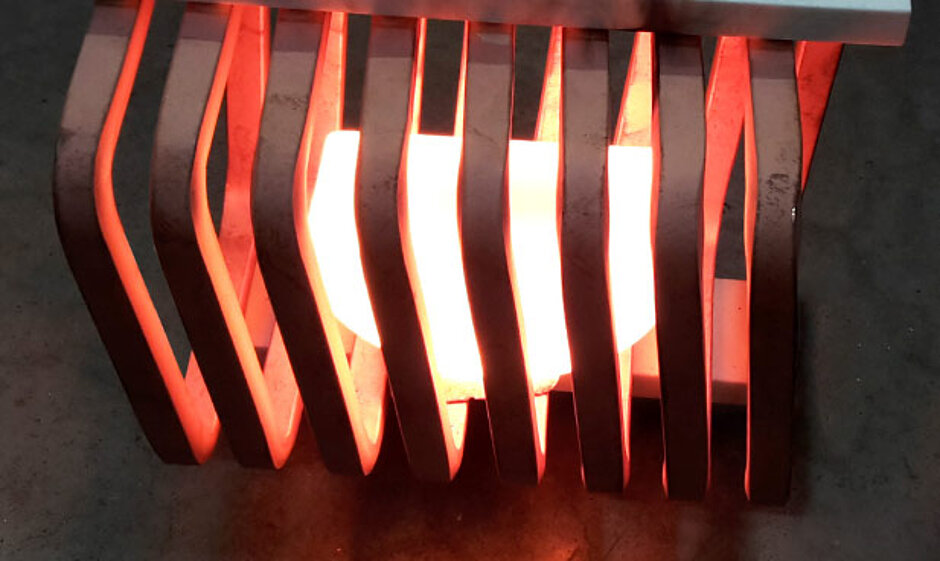

Smart Quality Control gives you the ability to adjust critical heating parameters in real-time and optimize heating requirements for your production. In doing so, we enable you to maximize product yield.

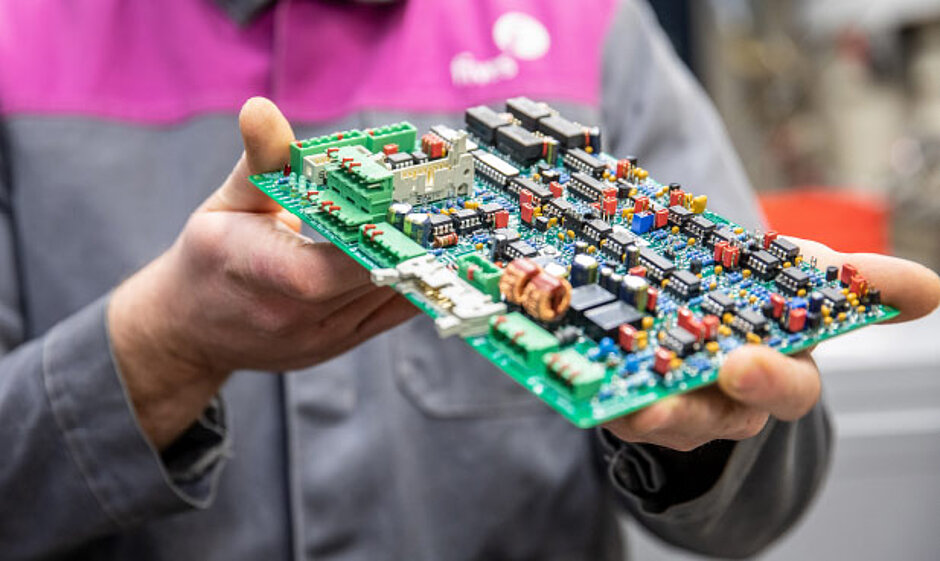

Gaining control

We will work with you to create a complete data management system, based on our CortX Alchemy software platform. From data collection to monitoring, analysis and visualization, this system will be tailored to your specific needs.

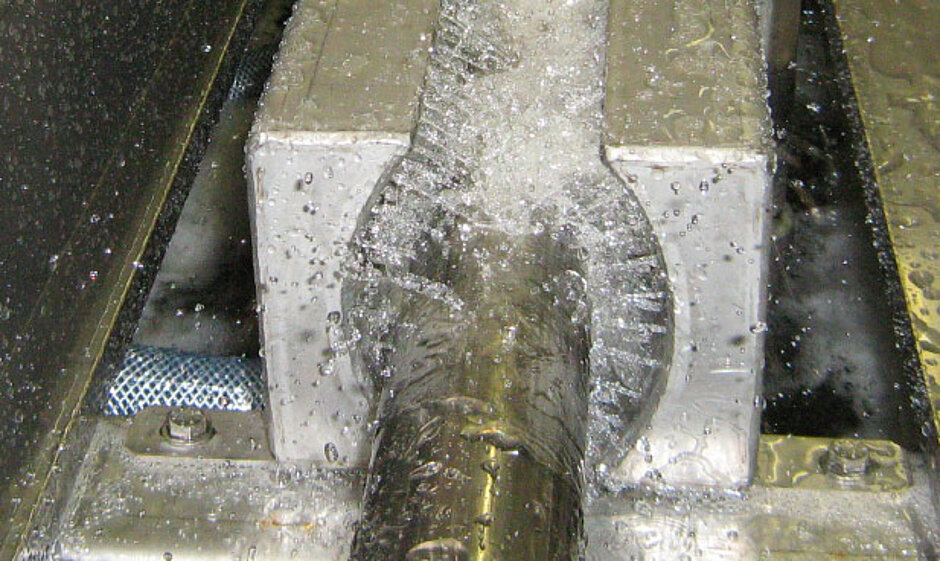

Importantly, CortX Alchemy is simple to implement. It just requires the installation of a Gateway module to the equipment. This device collects the relevant data points, including power, voltage, current, water flow, temperature measurements, alerts and faults.

- Remote alerting

- Enhanced fault diagnostics

- Best-in-class user interface

- Production traceability and reporting

- Predictive maintenance

- Improved customer support

Predictive modeling

Predictive modeling makes quality control even smarter

Using highly efficient database systems, CortX Alchemy retains a deep history of operational performance while reporting in real-time. Combined with machine learning capabilities and advanced data mining techniques, this forms the basis for developing predictive modelling.

By identifying and tracking all factors that influence quality, a predictive model identifies when operating parameters are diverging from optimal. This allows the system to correct or warn you before product quality is adversely impacted.

For example, at one manufacturing plant, predictive modelling and online quality control led to a 50% reduction in reject rate.