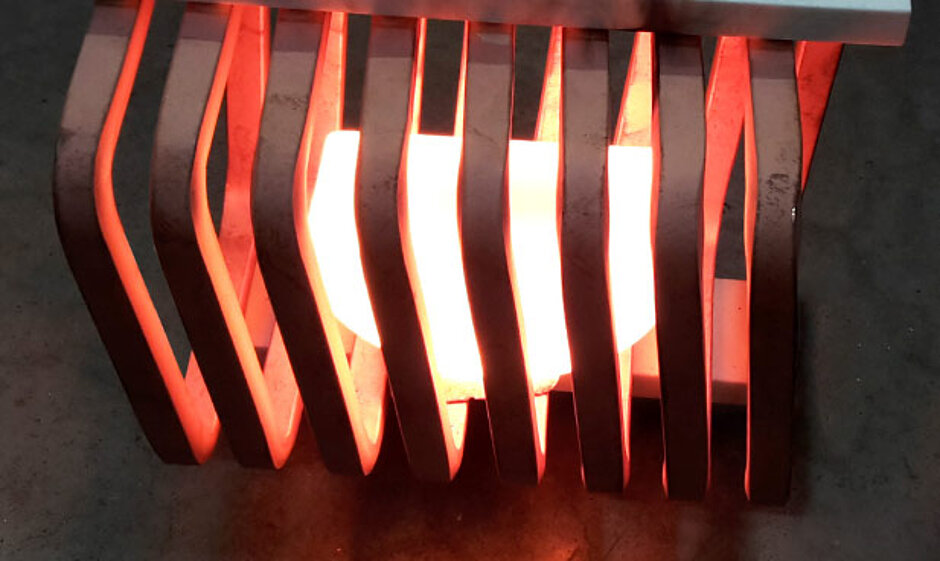

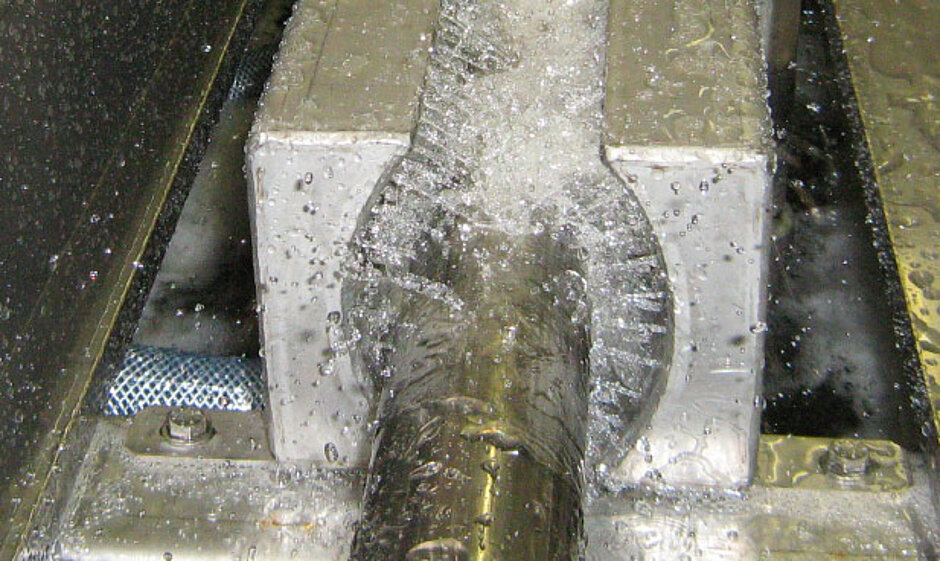

Induction tempering is applied following a quenching process, allowing the release of the various mechanical stress generated within the part, while maintaining the desired mechanical properties on the quenched area.

High stress relief

The entire part is heated to an adequate temperature (around 400°C depending on the type of material) and cooled in a slow or natural way, thus facilitating its stress relief by eliminating the various mechanical strains. Tempering allows the products to keep the mechanical modifications generated during a partial or total quenching, without weakening them.

Tempering is the best solution to:

- Maintain the required hardness of the steel

- Increase the toughness of the quenched steels

- Eliminate the stresses creating during quenching

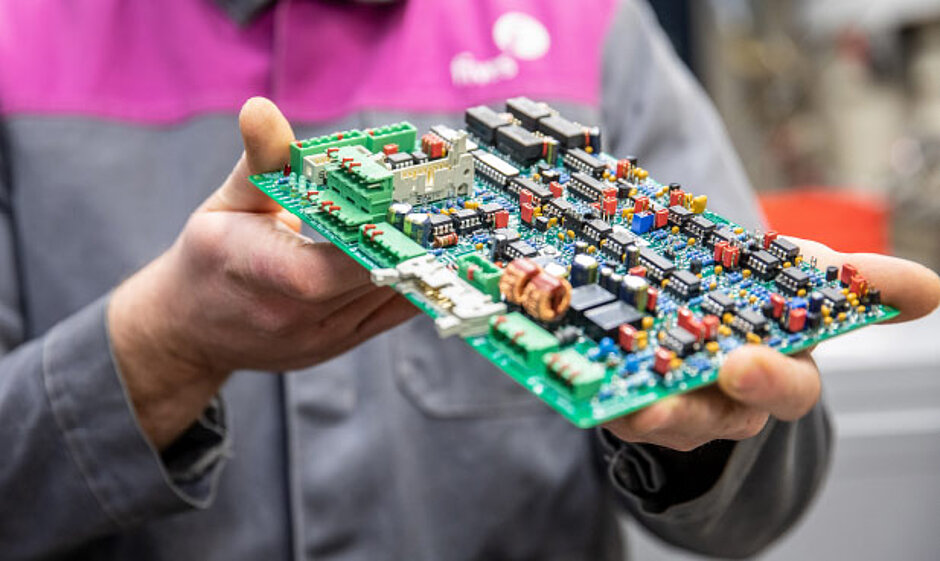

OUR INDUCTION SOLUTIONS:

Meet very precise mechanical properties specifications

Consume the right amount of energy

Easily integrate the tempering function into a production line