Discover an advanced new digital tool: Virtuo™ OptiScale, oxide scale control and reduction system. With this technology you can achieve oxide scale reduction of up to 30% and minimize the related quality, cost and maintenance concerns.

Oxide scale reduction

Oxide scaling is both a product quality issue and a productivity issue.

You spend time and money trying to achieve your desired surface quality and remove oxide scale from the furnace. It's an expensive job, and one that can't be avoided. But can it be simplified? Yes. Virtuo™ OptiScale is an advanced new digital tool designed to achieve oxide scale reduction efficiently and intelligently.

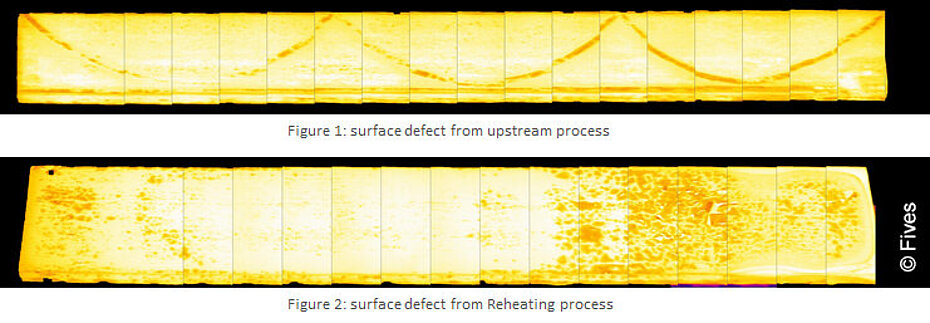

Using lasers and infrared cameras, Virtuo™ OptiScale scans the steel slab as it passes through the furnace. Then the system uses those images to analyse the distribution of non-adhering scale, the temperature of the slab and its overall surface quality. Its thermal protection system enables it to work in temperatures from 300°C to 1,300°C.

Virtuo™ OptiScale measures and maps oxide scale on the slab, identifying where problematic oxide scaling is occurring and automatically triggering changes in the furnace behaviour – via Virtuo™ – to minimize scale loss and even avoid non-adherent oxide scaling. Virtuo™ OptiScale was named as Solar Impulse Efficient Solution in 2021.

parameter adjustements

We use parameters such as temperature, residence time, product type and the composition of waste gases to help the tool build a profile of oxide scale growth. With this information, Virtuo™ OptiScale can automatically adjust furnace parameters to reduce oxide scale within the furnace and prevent non-adherent oxide scaling.

Even better, the software uses machine learning to continually evolve its understanding so that it can predict scale loss for all products being heated in the furnace. The modelling is automatically updated with the latest information from the furnace. With this technology you can reduce scale loss by up to 30% and minimize the related quality, cost and maintenance concerns.