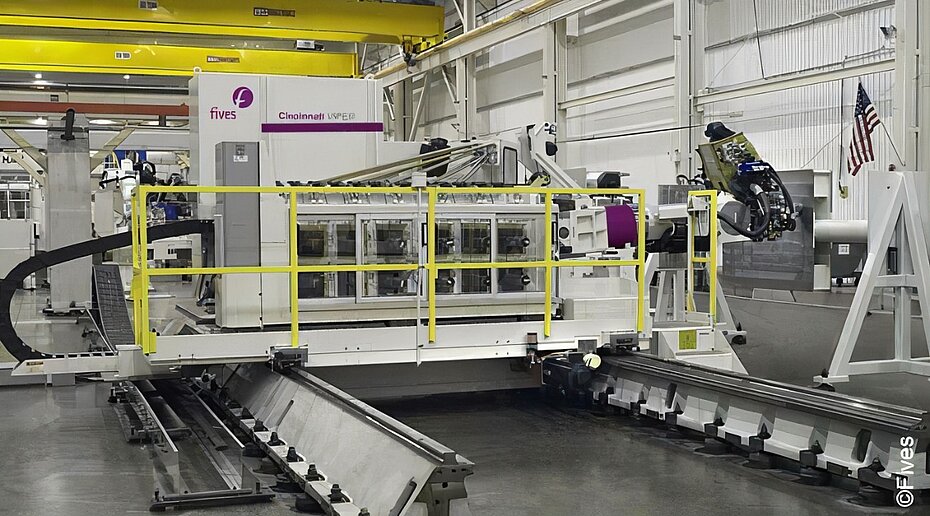

Versatile and advanced, our Cincinnati VIPER® 1200 automated fiber placement system provides unmatched production capabilities for parts up to 2 m diameter.

Automated fiber placement for convex and concave parts

Our Fiber Placement Systems are designed for dexterity and flexibility, enabling wrinkle-free lay-up of convex and concave parts. Combining tape laying and filament winding with cutting-edge controls, the Cincinnati VIPER® 1200 produces superior quality while dramatically reducing scrap.

Cut your costs with the VIPER® 1200

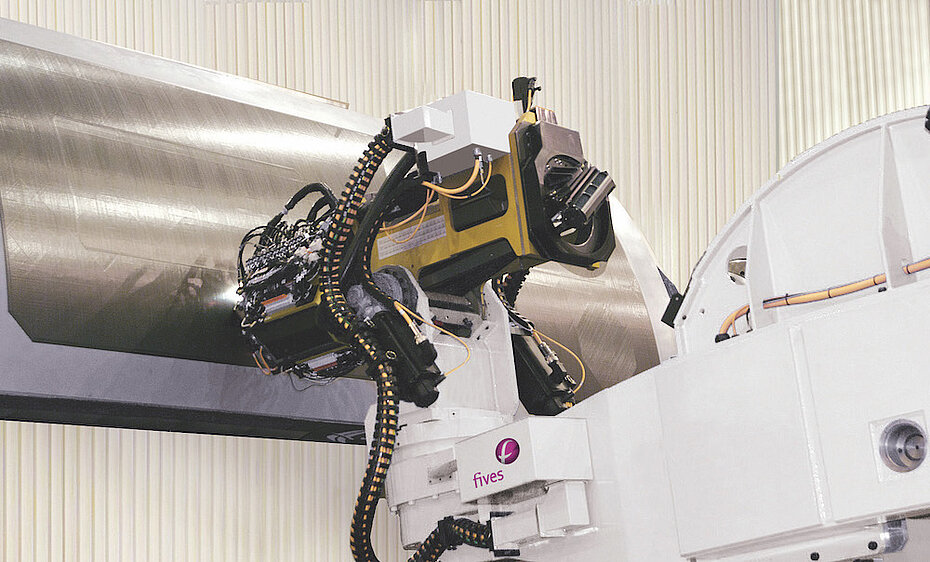

With seven axes of motion, VIPER Fiber Placement Systems are particularly suited to highly contoured structures. The agility of the Cut-Clamp-Restart (CCR) system enables precision tape laying and reduces material waste at every stage. Each tow can be independently dispensed, clamped, cut and restarted during fiber placement. Gaps and overlaps are minimized, as the machine precisely lays interior or exterior contoured boundaries.

The VIPER® 1200 produces parts up to 2 m (80 in) diameter, using 12 tows: 3.2, 4.0 and 6.4 mm (0.125, 0.157 and 0.25 in).

Additional benefits of the VIPER® 1200

- Superior compaction on core and tight radii contour surface features

- Optimum surface finish thanks to precise tension control

- Low risk of twisted tows due to Re-direct Roller System

- On-the-fly adjustment of fiber band width with Individual Tow Cut-Clamp-Restart