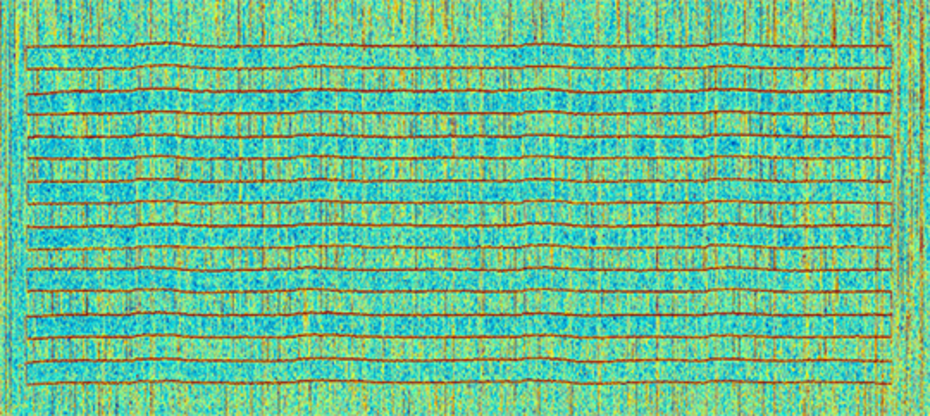

In-line inspection provides quality assurance during the lamination process. Laser line triangulation measurement systems ensure your parts meet specification, every time.

Off-the-shelf laser line triangulation measurement systems

If you are manufacturing relatively simple composite parts, a laser line triangulation measurement tool is all you need. We work with a number of vendors to provide off-the-shelf systems for basic quality assurance.

Drawing on our experience across the complete composite manufacturing process, we’ll find the right tool for your task. We also offer a customized option – the Bliss sensor – for applications not suited to a standard laser line triangulation tool.

Ideal solution for flat parts

Laser line triangulation (LLT) measurement systems work best with less complex, flatter parts. Working in tandem with our SuperCharger automated tape laying solution, these LLT instruments help ensure perfect geometries, every time. For the simpler applications, we buy in LLT tools from a range of manufacturers – always choosing the best tool for your process.

When the application specifics determine that a simple solution won’t do the job, we offer an alternative. The Bliss sensor is a dual image, custom-built tool that ensures you always get the type and quality of images you need. This tailored solution delivers improved quality assurance on more complex applications that can still be served by laser line triangulation.

Where LLT measurement systems are not sufficient, we recommend our optical coherence tomography (OCT) solution.