Quality is everything. So, we design forming, curing and inspection solutions that provide maximum quality assurance. We also integrate proven technologies from third-party providers to develop end-to-end solutions that produce optimum results.

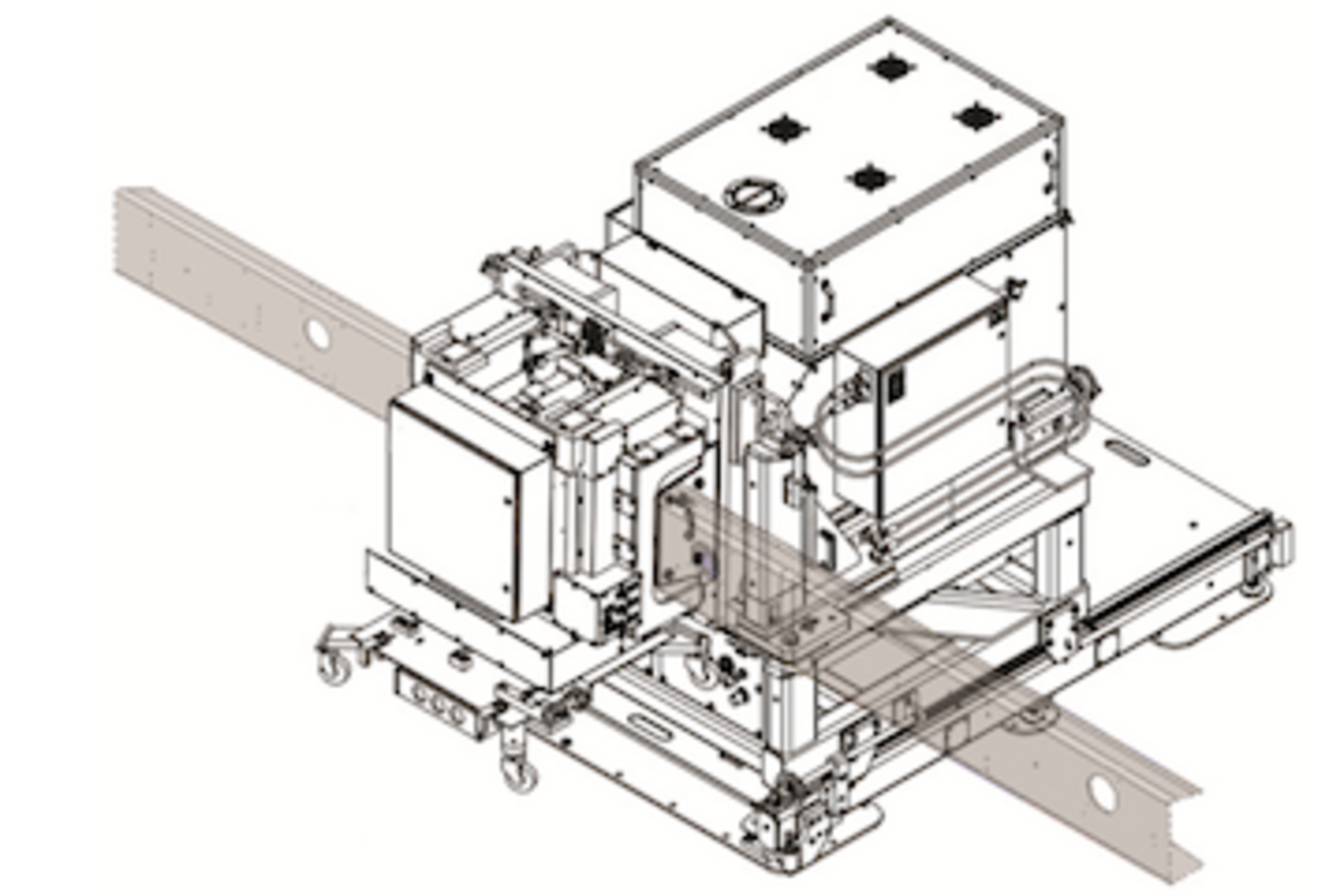

INTEGRATED COMPOSITE FORMING SOLUTIONS

We offer a complete range of forming solutions for your composite manufacturing needs. Our expertise spans vacuum drape, mechanical shear and sequential ply forming machines. We can also develop bespoke forming processes. So whatever the application, you can count on us to provide the best solution for you.

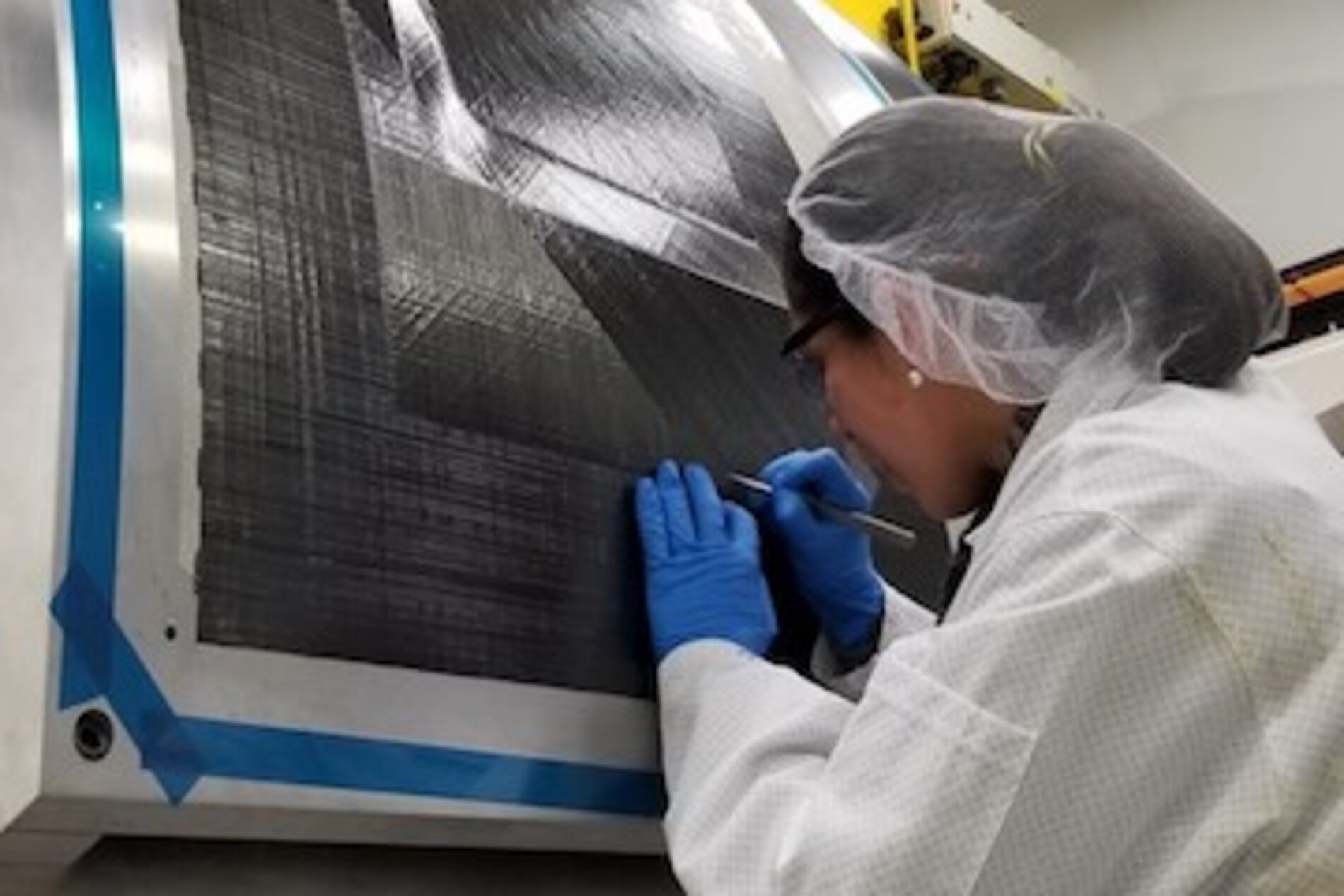

RAPID, RELIABLE POST-CURE INSPECTION TOOLS

Speed up post-cure inspection processes with our bespoke ultrasonic inspection solutions. We integrate proven technology within a system design that’s tailored to your needs.

RELIABLE OFF-THE-SHELF IN-PROCESS INSPECTION TOOLS

We integrate off-the-shelf laser line triangulation systems into your process for reliable inspection of simple composite parts. Our experience and expertise in composite manufacturing means we’ll always find the best tool for your task. We can also offer a customized option for non-standard applications.

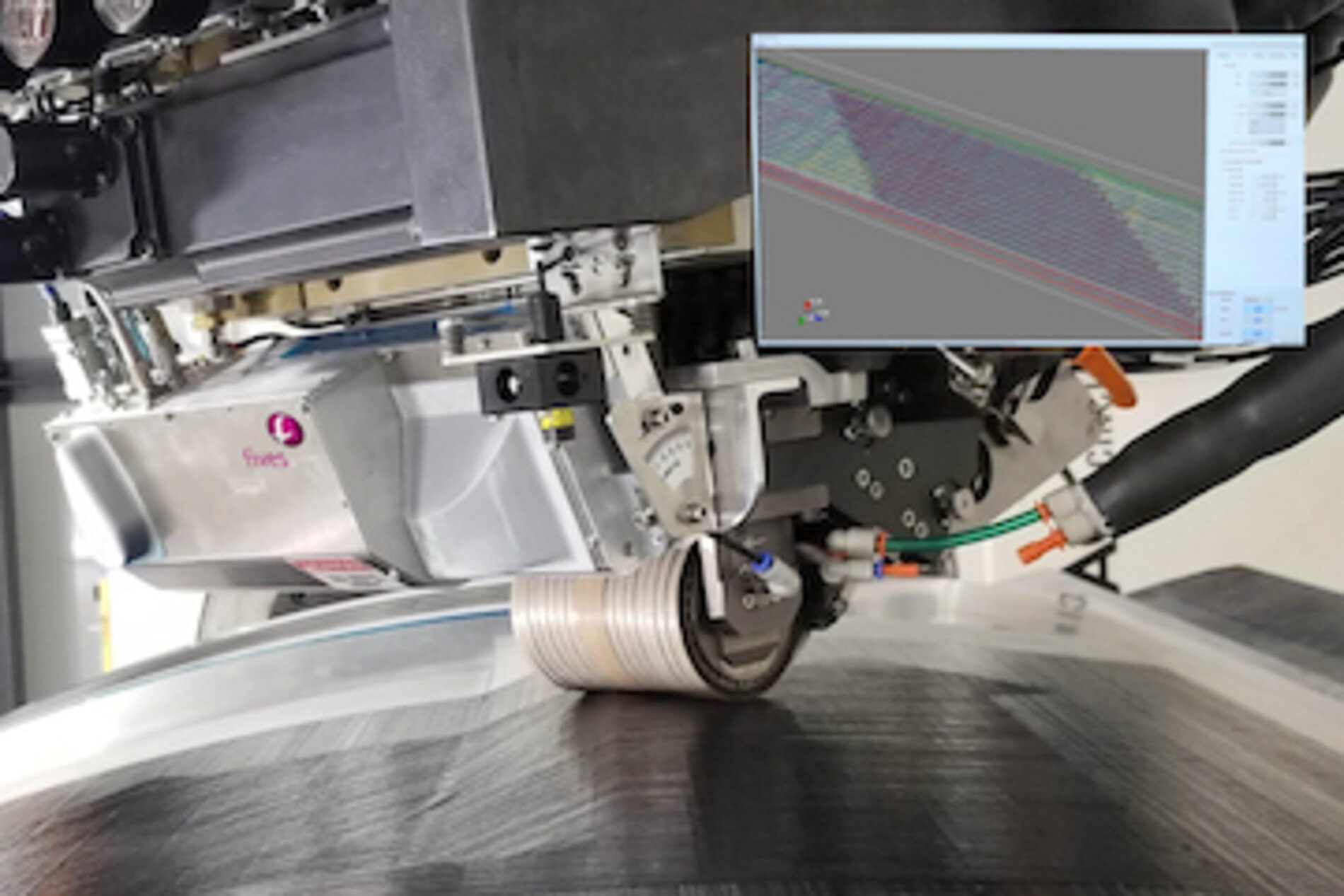

IN-PROCESS INSPECTION TOOLS FOR MORE COMPLEX TASKS

For applications with highly-contoured surfaces or using a range of materials, we recommend our optical coherence tomography (OCT) solution. State-of-the-art software converts 2D profiles into a 3D image of the course. Integrated seamlessly into the process, OCT is an evolution in sensing technology.

FOR ULTIMATE PEACE OF MIND, ADD VISION INSPECTION

Easy to integrate with OCT, our industrial vision solutions provide maximum quality assurance. Automatically assess part shape and size, and inspect for foreign objects. It’s more efficient than manual inspection – and easier to identify patterns of defects to improve programming.

COST-EFFECTIVE CURING

Covering every aspect of composites manufacturing, we are your go-to for bonding and curing. Our highly-automated, out-of-autoclave solutions offer optimal performance and precision with lower energy costs compared to traditional methods.