Smart combustion for a more sustainable future

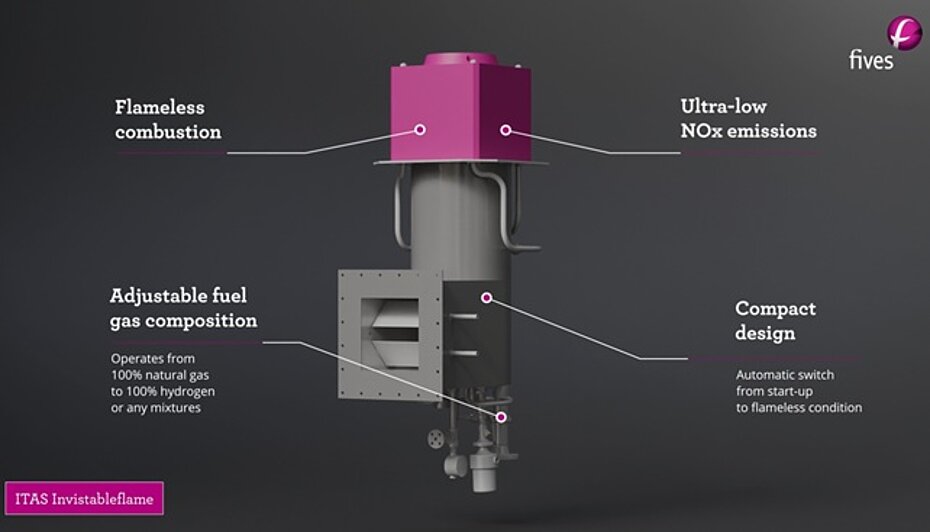

ITAS Invistableflame is an innovative and hydrogen-proven burner designed to meet the challenges of hydrogen-rich fuels and stringent NOx regulations.

With no visible flame and a simplified burner architecture it ensures uniform temperature distribution and highly reduced emissions, particularly for steam methane reformers (SMR) applications.

Patented ultra-low NOx technology with unparalleled fuel flexibility

ITAS Invistableflame reduces thermal NOx formation through flameless combustion.

By avoiding hot spots and using internal flue gas recirculation, it achieves ultra-low NOx levels even in hydrogen-rich environments, meeting the most demanding environmental standards.

This breakthrough technology, which won the 2024 Fives Innovation Awards, offers unparalleled fuel flexibility, going from 100% natural gas to 100% hydrogen.

Simplified compact design for lower costs of installation and maintenance

Unlike flameless conventional systems requiring dual burners and mechanical switches, ITAS Invistableflame integrates start-up and operation in a single compact unit.

Fuel or phase switching occurs without mechanical intervention, reducing complexity, risks and costs. It handles extreme temperatures with ease.

ITAS Invistableflame is ideal for retrofitting existing SMR and process heater installations, thanks to its space-saving layout and streamlined configuration.

High technical performance and applications

ITAS Invistableflame is engineered for high-performance and reliability:

• Fuel flexibility: 100% NG to 100% H₂

• NOx emissions: ultra-low

• Simple design: compact, no mechanical switch, lower costs

• Increased safety: fewer components, lower risks

ITAS Invistableflame burners address the needs of various applications operating in high-temperatures and looking to significantly reduce their emissions.

Thanks to its fuel flexibility, the burner is not limited to natural gas or hydrogen: it can also operate with other fuels typically used in SMR processes.

Applications include:

• Steam methane reformers

• Ethylene cracking furnaces

• Process heaters

• Other reformers

• Hydrogen-based combustion systems

• Clean energy industrial plants