CASE STUDY: Lincoln Park Boring Expands Capabilities with Giddings & Lewis RT 130

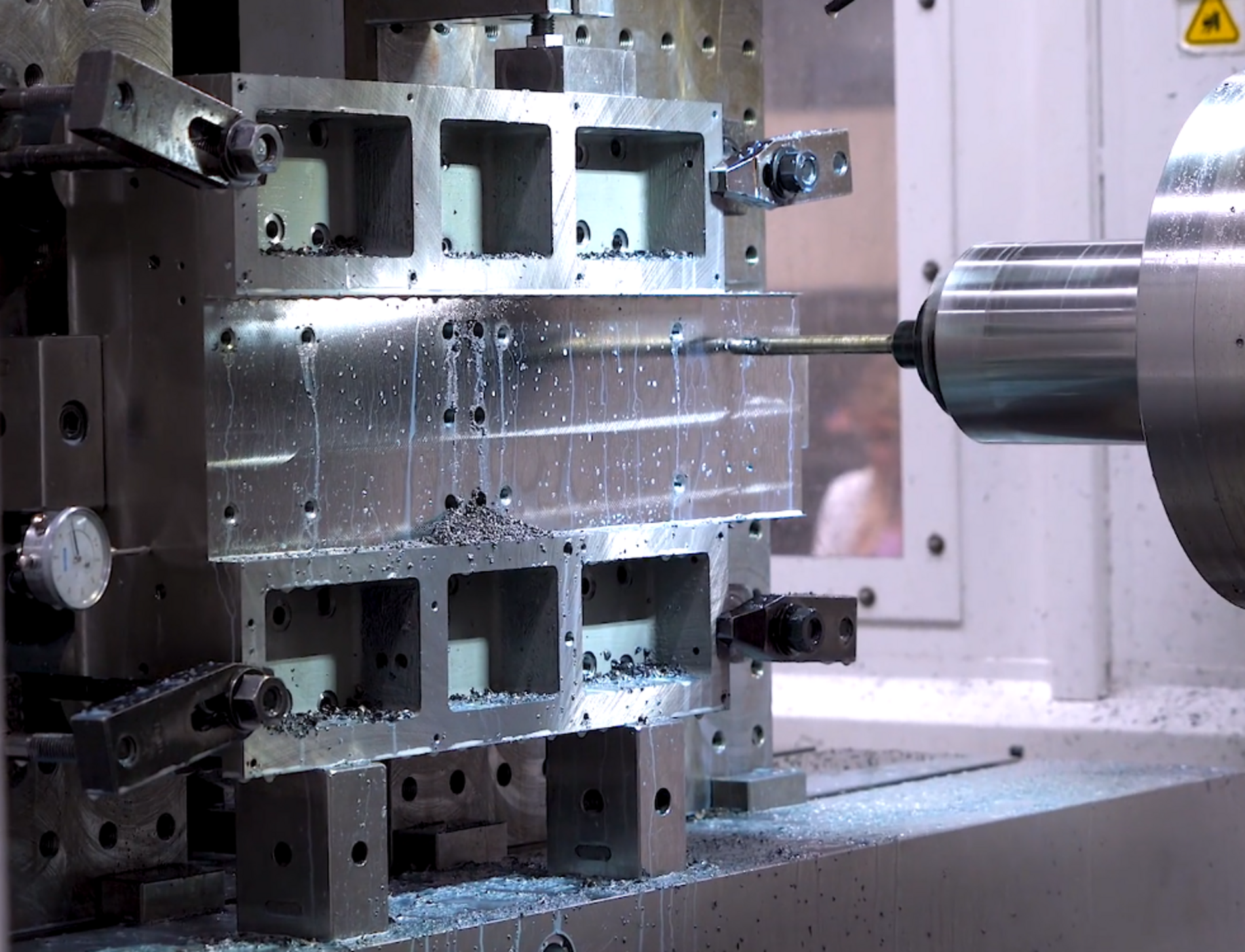

GIDDINGS & LEWIS T-BED HORIZONTAL BORING MILL

Lincoln Park Boring Co. invested in a new boring-mill machine from Fives with a FANUC control to hold tighter tolerances and accommodate rapid travel rates for faster machining.

CHALLENGES

- Transition of legacy Giddings & Lewis equipment to new machines

- A cost-effective solution to deliver accuracy, repeatability, and ease of maintenance

SOLUTION

As Lincoln Park Boring Company continued to expand into new types of work—including larger, more complex parts—the company needed equipment that could deliver greater capacity, precision, and reliability. Having long relied on Giddings & Lewis machines, Lincoln Park once again turned to Fives to provide a solution that would meet its evolving production needs.

The result was a new Giddings & Lewis RT 130 T-bed horizontal boring mill—a cost-effective, heavy-duty machine designed to maximize productivity without compromising quality. Built from cast iron and engineered for exceptional stiffness and accuracy, the RT 130 provides the durability and precision that Lincoln Park requires for tight-tolerance work. Its 10-ton hydrostatic table with full 360° clamping and electronically counterbalanced headstock ensure superior contouring and stability, even under the most demanding cutting conditions.

To deliver the flexibility Lincoln Park needed for both high-mix and low-volume production, Fives integrated a FANUC 0iF CNC system. As a FANUC Authorized Integrator, Fives collaborated closely with FANUC to tailor the control interface with a custom subplate, joystick, and integrated speed and feed controls—allowing operators to run the machine manually for short runs or switch to full CNC operation for production work.

The combination of Giddings & Lewis precision engineering and FANUC control performance has allowed Lincoln Park to take on more challenging work, hold tighter tolerances, and improve throughput. Impressed with the machine’s performance, the company has since partnered with Fives again to retrofit one of its legacy Giddings & Lewis machines with new FANUC controls, extending its life and bringing modern performance to trusted equipment.

Whether it’s delivering a new Giddings & Lewis machine or performing retrofits and rebuilds on legacy equipment, Fives provides end-to-end solutions that help manufacturers modernize operations, improve productivity, and stay competitive.

RESULTS

- Increased efficiency

- Improved capabilities

- Tighter tolerance

“We’ve grown and worked together (with Fives) on a number of things such as this control that helps this machine be more useful for low quantity parts. This machine has many more capabilities than the machine it replaced.”

Rick Yesue

President

ABOUT FANUC

Leader in factory automation and manufacturing technology

The company specializes in developing and supplying products like industrial robots, Computer Numerical Control (CNC) systems, and high-speed machining centers used across various industries worldwide. Their core philosophy is "Service First," which includes a commitment to lifetime maintenance for all their products.

ABOUT Lincoln Park Boring Company

For more than 60 years, this family-owned and operated business has handled the production of large parts and metal fabrication across different industries. The Lincoln Park Boring Company largely specializes in manufacturing parts of larger machines used to produce components for woodworking, machine tool cutting, grinding, and more.

Connect with an expert

CONTENT FOR YOU: