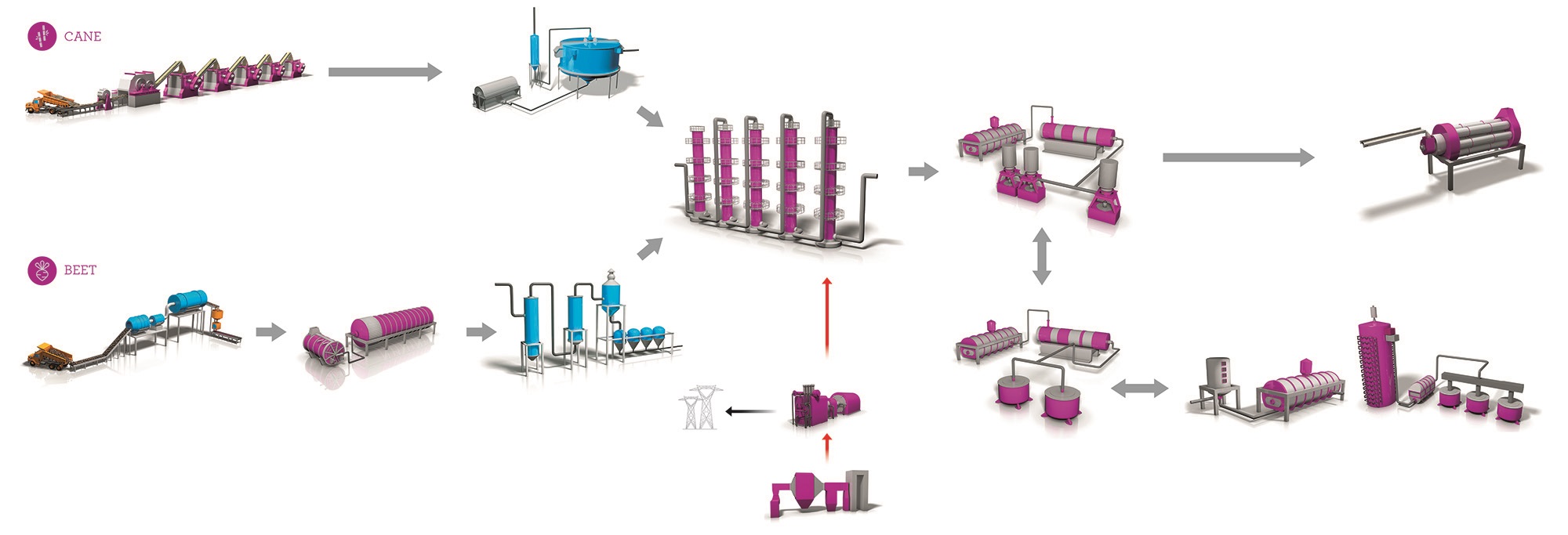

Equipment

for sugar production

Fives’ equipment ensures reliable and flexible operations at every stage of sugar production. Our designs include the largest equipment on the market, offering optimal performance and energy savings for our clients. We also provide digital solutions and services for safe, cost-effective operations throughout the equipment lifecycle.

CUSTOMER'S VOICE

Discover how Fives can support you in your production challenges with state-of-the-art equipment and wide project management experience, through the success story of Lesaffre Frères sugar plant in Nangis

> Improving sugar recovery while limiting energy consumption

Preparation equipment for greater sugar plant performance

Fives’ heavy-duty in-line and vertical cane shredders prepare sugarcane prior to extraction. Our Cail & Fletcher in-line shredder drastically reduces maintenance costs and downtime and uses 25% less power than conventional cane preparation equipment. The Cail & Fletcher vertical shredder is an efficient solution to maximize sucrose recovery. It offers efficient energy conversion and an effective shredding action, with minimum wear.

High-efficiency sugarcane juice extraction equipment with low power consumption

Our Cail & Fletcher MillMax® and conventional heavy-duty mills extract cane juice while ensuring low bagasse fuel moisture prior to combustion.

They are available as direct mill replacements or as a complete milling tandem. The MillMax® offers 25% savings in maintenance time, while the conventional heavy-duty mill’s flexible and robust design ensures a long equipment lifecycle.

Evaporation solutions with advanced design

The Cail & Fletcher falling film evaporators are widely recognized as the best operating evaporators on the market. They are known for their simple design and high thermal efficiency. Concentrated juice coming from the purification station is evaporated and sent to the crystallization station, and vapor is distributed as needed throughout the plant.

Industry standard sugar crystallization technology

Fives’ renowned crystallization technologies are fully automated, flexible and energy efficient. Our Cail & Fletcher Continuous Vacuum Pan and barometric condenser represent the industry standard for cane and beet crystallization and evaporation. The Cail & Fletcher cooling vertical crystallizer maximizes molasses purity drop by controlling the massecuite viscosity and cooling temperature.

High-grade massecuite centrifugation equipment

Our Cail & Fletcher ZUKA® and D412 batch centrifugals are worldwide references in high-grade massecuite centrifugation. They facilitate centrifugal separation of the mother liquor and crystal sugar in cane and beet plants and refineries. The Cail & Fletcher FC1300/1550 continuous centrifugals separate sugar crystals from massecuite with minimum sucrose loss. The brand-new Cail & Fletcher e-Crystal™ continuous centrifugals offer furthermore the highest crystal quality and stand-alone operation.

Rotary drum dryers with maximum crystal preservation

Fives’ Cail & Fletcher multitube and monotube sugar dryer-coolers carefully preserve crystals for improved conservation and storage. Their configuration uses vacuum circulation of hot and cool air via a single fan, while bacteriological filters eliminate contamination. The equipment can handle large capacities, while being compact enough for easy installation in plants with limited space.

Monotrac and Hydrotrac probes for enhanced brix performance

The Cail & Fletcher Monotrac probe facilitates dry matter measurement and offers automated control. This improves brix monitoring throughout the manufacturing process, from batch and continuous vacuum pans and evaporation stations, to other applications.

Based on microwave technology, the Cail & Fletcher Hydrotrac probe offers even greater functionality. It provides dry matter measurement without sensitivity to purity variation, and includes direct temperature readings.