Reducing the carbon footprint

Taking the lead in the industry’s energy transition

Industrial combustion solutions and processes have a significant impact on the environment.

Fives is committed to helping manufacturers worldwide reduce their carbon footprints, in line with the Paris 2015 Climate Agreement.

We deliver the most effective low-carbon solutions for combustion processes and customer operations as we work toward a sustainable future.

Together, we can ignite the change.

Innovative combustion systems for a carbon-free future

Our R&D programs and joint innovation projects have led to cutting-edge hydrogen burner designs and electrical heating systems. These solutions are key to completely cutting carbon emissions from your combustion and heating processes:

-

Hydrogen combustion: With the largest hydrogen-compatible burner portfolio in the industry and dedicated R&D facilities, Fives is your partner of choice for combustion of hydrogen.

Our hydrogen burners -

Electrical heating: When green electricity is available, electrical heating is the solution of choice for low- to medium-temperature processes.

e-Ductflame: hybrid hot air generator for drying applications

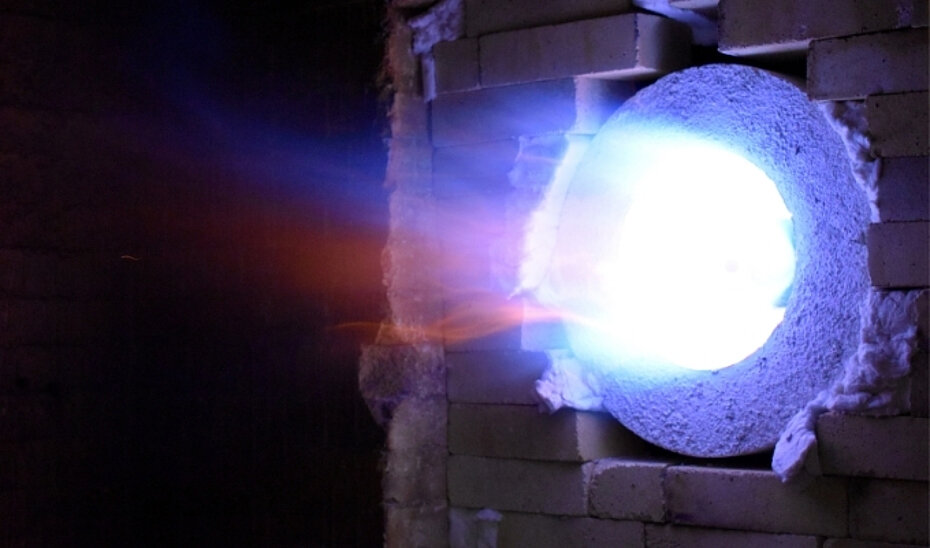

Reducing CO₂ and NOx emissions with better burners

As an industry leader, we continually develop new products that reduce CO2 and NOx emissions while improving process efficiency:

Low and ultra-low NOx burners

The majority of products in our range offer high-quality combustion and reduce atmospheric NOx levels. Our latest innovations include:

-

The North American EcoFornax,™ a lean, multipurpose premix burner that reduces NOx emissions below 20 ppm

-

The ITAS Dryflame, our latest generation of nozzle mix compact corner burners, ideal for low-temperature applications

-

The Pillard NANOxFLAM® and the Pillard NANOxFLAM® Compact, Fives’ latest ultra-low NOx industrial gas burner based on patented Pillard BLUEMix® technology

See our full catalogue to find the right fit for your process.

Heat recovery solutions

-

The North American Twinbed™II is Fives’ advanced regenerative burner that reduces NOx and CO2 emissions for high-temperature furnaces

- The North American Evenglow™ LNx, combined with its plug-and-play 8480A Recuperator, offers improved temperature uniformity for metal processing lines along with increased energy efficiency

- Pillard INDUCTFLAM® duct burners ensure the highest performance for Heat Recovery Steam Generator (HRSG) applications

Pollutant destruction

-

Fives supplies a complete range of volatile organic compound (VOC) abatement technologies. From regenerative thermal oxidizers to sulfur recovery units and ultra-low NOx oxidation solutions, we help you eliminate any pollutant from your exhaust stack

Alternative fuels

Fives aims to optimize energy usage throughout the combustion system and to limit waste.

-

Alternative solid fuels (ASF): The Pillard NOVAFLAM® Evolution is our premium, multichannel burner for rotary kilns in cement plants. Thanks to its unparalleled combustion efficiency, Fives’ burners can co-fire a large amount of carbon-neutral alternative solid fuel while improving clinker quality. This helps reduce the carbon footprint of the cement plant as well as gaseous pollutant emissions.

-

Biomass: The Pillard GRFLAM™ CP burner is designed to fire pulverized biomass in boilers and hot gas generators

-

Biogas: The Pillard NANOxFLAM® and the Pillard BIOFLAM™ burners are able to fire up to 100% biogas even with LHV.

Nearly the entire ITAS product line is biogas-compatible. For complete details of all products, please see our product finder. -

Liquid Waste Fuels: all Pillard burners can be equipped with waste fuel guns to fire on boilers, kilns and incinerators.

Smart technologies

Our combustion experts design digital solutions to help you optimize your equipment use, reducing fuel consumption and emissions.

-

The North American CertiFire™ is the state-of-the-art solution for temperature uniformity surveys of industrial furnaces. Save up to 90% in survey time preparation and get increased tunning accuracy.

-

Pillard NOVASMART® technology enables you to monitor your rotary kiln burner operation status, detect and diagnose deviations, and modify the burner setting to ensure perfect combustion.