Rotary kiln burners

Maximum-efficiency, low-emissions rotary kiln burners

Fives designs world-class rotary, custom-designed kiln burners for processing cement and minerals such as lime, alumina and iron ore pellets. Our experts use computational fluid dynamics (CFD) modeling to develop these highly efficient, reliable and sustainable burners. Our innovative firing technologies can be tailored to meet our clients’ needs.

High-performance design for the cement industry

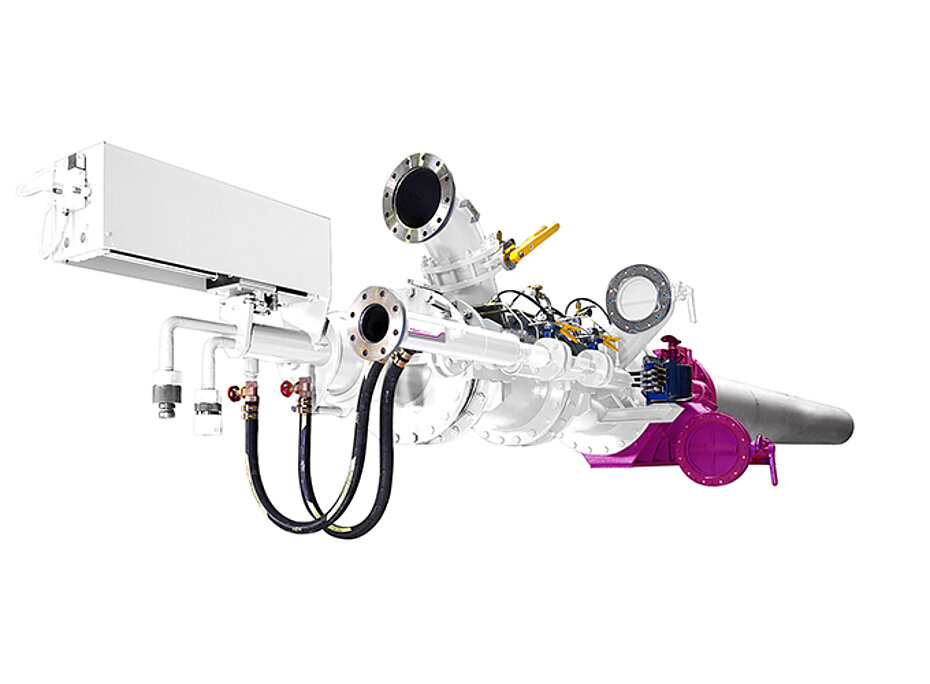

The Pillard NOVAFLAM® Evolution meets the specific needs of the cement industry. This latest-generation Pillard NOVAFLAM® rotary kiln burner minimizes NOx and CO emissions thanks to its low-NOx design and enhanced alternative solid fuel (ASF) substitution rate.

Available from 8 to 200 MW power, this premium mono- or bi-channel burner combines a variety of breakthrough innovations that make it highly resilient:

-

Longer burner and kiln refractory lifetime

-

Greater burner adaptability

-

High cement clinker quality and production rate

-

Optimum fuel flexibility

-

Strong thermal efficiency

Flexible processing for pellets and minerals

Stoichiometric solutions

Depending on the level of emissions required, North American Ultra-Low NOx EcoFornax LEx or North American Low NOx Magna-Flame 4796 burners can be utilized for mineral drying or calcining. The flexible design and capability to fire a wide range of fuels makes these burners suitable for almost any rotary kiln application.

Sub-stoichiometric solutions

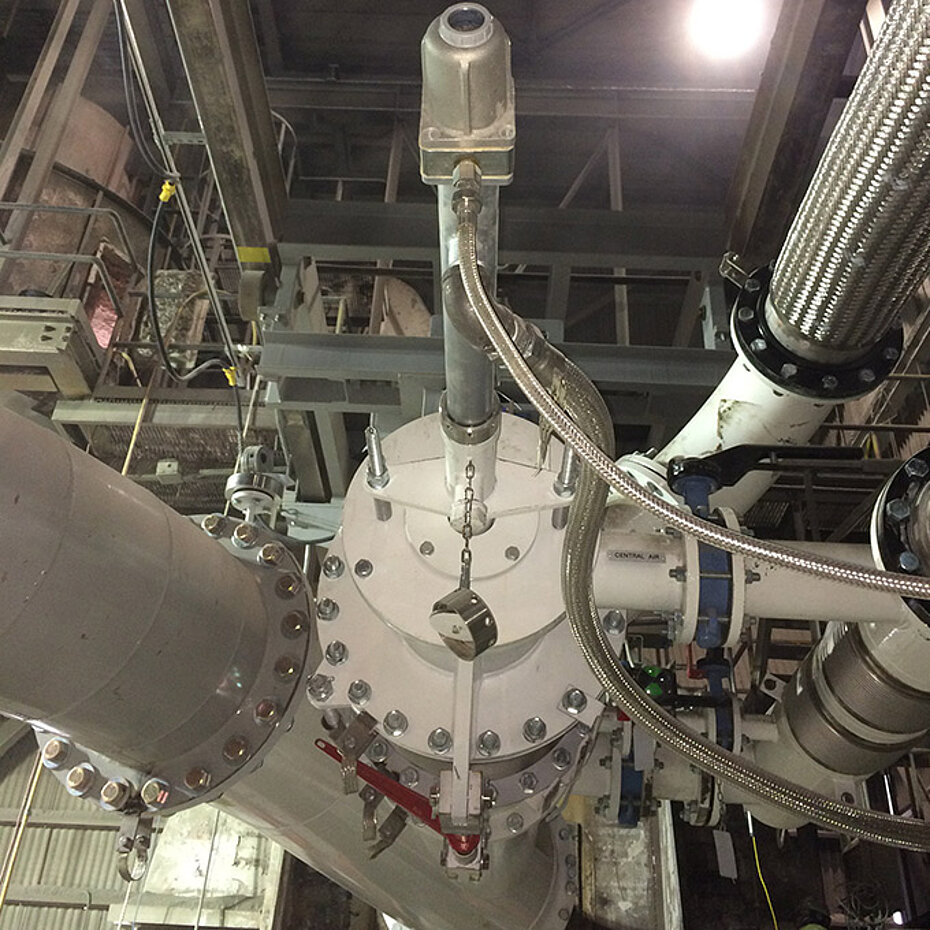

The Pillard ROTAFLAM® is the first flexible, multi-fuel rotary kiln burner for non-ferrous minerals pyroprocessing and iron ore pelletization. For more than 20 years, the Pillard ROTAFLAM® has been successfully used in a wide range of non-cement calcinations and reduction processes including:

-

Quicklime

-

Dolomite

-

Pulp & paper lime recovery

-

Iron ore

A central flame stabilizing system guarantees a steady flame even from a cold start and with low secondary air temperatures. Its high combustion efficiency lowers residual CO emissions.

Improve efficiency and simplify maintenance for cement and lime production

The Pillard DNOxFLAM™ is a low-NOx burner for rotary kilns that offers high combustion efficiency and low operational costs. The Pillard DNOxFLAM™ is used in cement, lime and all other mineral processes using rotary kilns.

The Pillard DNOxFLAM™ delivers average NOx reductions of 20%, compared to conventional direct fired mono-tube burners. It can be installed in direct firing systems without modifying existing equipment. This unique technology offers, among other advantages:

-

Improved flame stability

-

Faster ignition of pulverized coal particles

-

Reduced black plume length

-

Burner light-up and flame detection system

-

Simplified maintenance

Product Finder

Find the combustion solution that fits your needs

Browse and download our related product literature