Minerals

Low-emission combustion technology for processing industrial minerals

Fives’ combustion solutions can support clients through every step of the mineral calcining and drying process. Our burners reduce operating costs and lower emissions without compromising plant efficiency. We also offer process services and fuel management systems to help you optimize your mineral production.

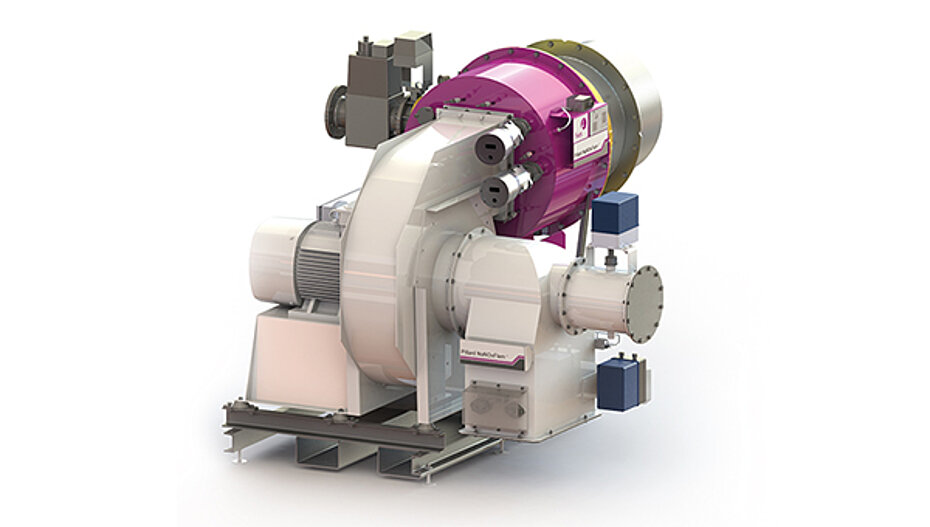

Rotary kiln thermal solutions for minerals processing

Rotary kilns are used to process many minerals and waste streams. Lime, which is used across multiple industries including pulp and paper, cement and steel, is processed primarily in rotary kilns.

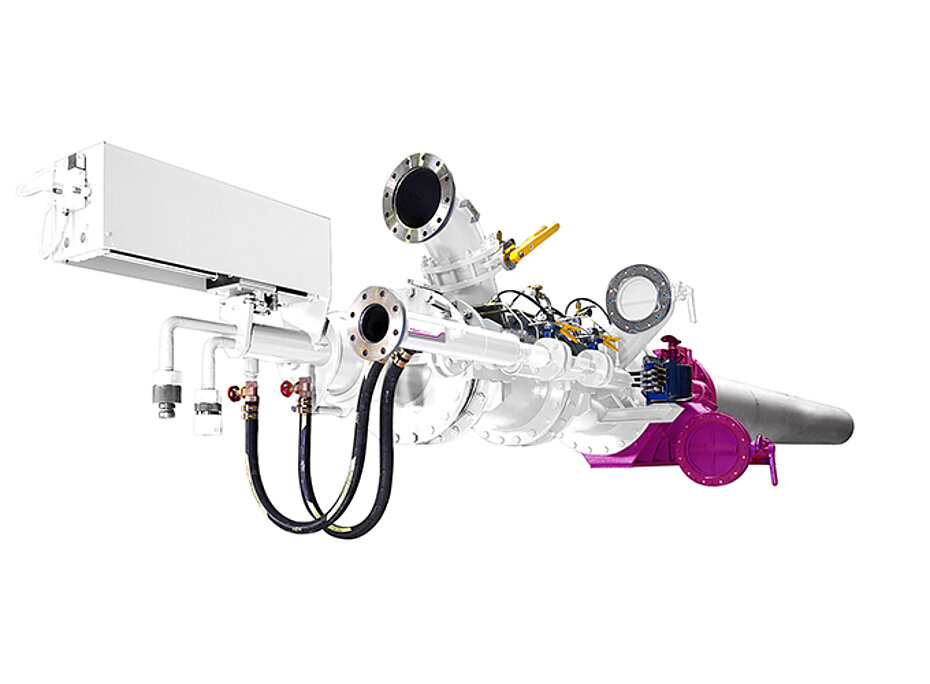

Pillard ROTAFLAM® is a leading rotary kiln burner for calcination and reduction processes. This multi-fuel burner guarantees flame stability and lower NOx emissions. It is adaptable and can be integrated into existing installations. Pillard ROTAFLAM® is compatible with any type of fuel, making it the ideal solution for all lime processing plants.

Fives also offers a wide array of low-emissions burners that can power rotary kilns and dryers. All are long lasting and customizable to match your fuels and kiln designs for best performance:

Recirculating dryer and calciner thermal process solutions

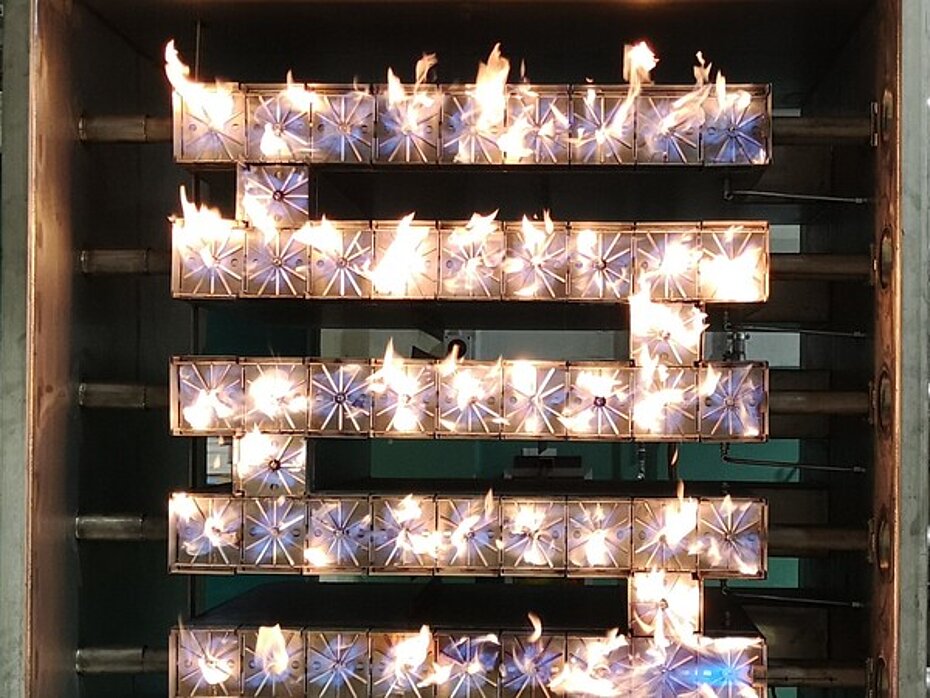

Fives develops premium duct burners for gypsum board drying. ITAS Ductflame burners are used in hot air heater applications where air flows vary in quantity, pressure, temperature, humidity and oxygen content. The burners’ modular design facilitates different configurations and capacities ranging from 100 kW to 30 MW:

-

For hot upstream process flow or flow containing limited oxygen: ITAS Ductflame F

-

For relatively cold upstream process flow containing limited oxygen: ITAS Ductflame L

-

For situations requiring careful control of recirculation flow composition: ITAS Ductflame R

The latest Fives innovations can help you achieve the lowest process emissions without affecting efficiency. Using lean premix technology, our trusted and robust burners reduce emissions without compromising product quality and combustion control. Our burner options include:

Powering ceramic and brick production

Kilns are integral to ceramic and brick production. Our kiln burners perform high velocity entrainment, penetration and furnace gas recirculation while maintaining temperature uniformity and thermal efficiency.

-

Ensure temperature uniformity for a variety of applications with the North American Tempest® 4441 High Velocity Gas Burner, a high velocity jet for re-circulation

-

Enjoy high excess air ratio capabilities with the lightweight all-metal North American 4575 HiRAM® burner

Fives’ burners maintain consistent temperatures throughout drying processes, delivering high-quality products. A simplified combustion control system and fewer components reduce failure risk while increasing uptime. Our burners for the ceramic and brick drying process include:

-

Control temperature and air flow for optimal product quality with ITAS Ductflame burners

-

Generate hot air for drying processes with ITAS Dryflame burners, our latest generation of nozzle-mix compact corner burners

-

Enjoy complete flexibility with the customizable North American Zephyr™, and choose from an array of accessories and added features to meet your unique production needs

Product Finder

Find the combustion solution that fits your needs

Browse and download our related product literature