Fences, pushers and flags significantly impact the production process. Fences and pushers ensure that the glass ribbon follows a predetermined position within the tin bath, preventing it from swinging. Flags are used to control cold tin back-flow.

The width of the glass ribbon is easily managed using a non-contact pusher and fence mechanism, along with a smart flag system that regulates currents with carbon flags.

⇥ BENEFITS

|

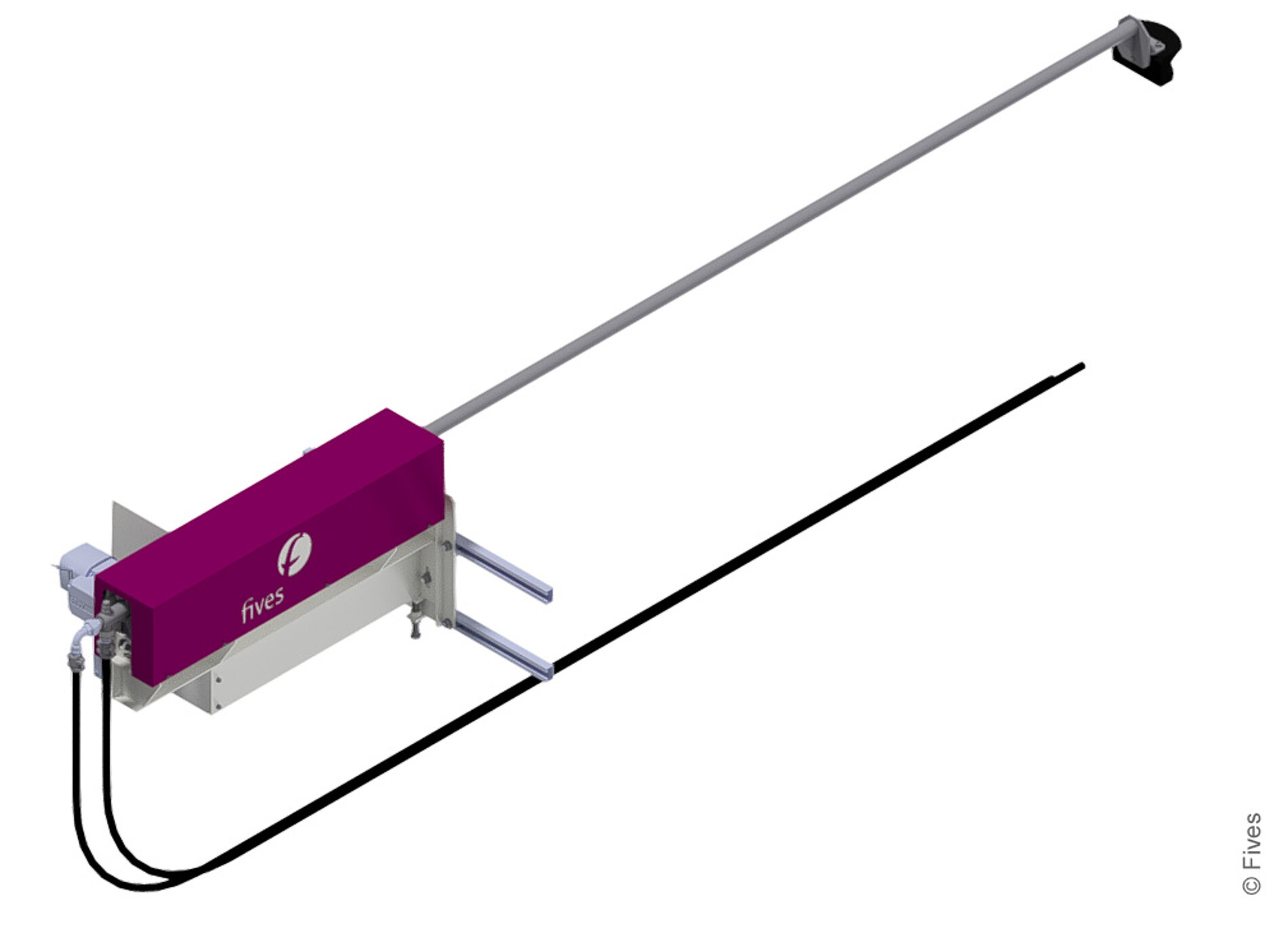

Fence & pusher

The fence is used to maintain the alignment of the glass ribbon in the tin bath. The pusher is a safety device that helps reduce the width of the ribbon at the entrance to the narrow section of the bath in case of malfunction.

Unified design: the two machines differ only in the graphite working element.

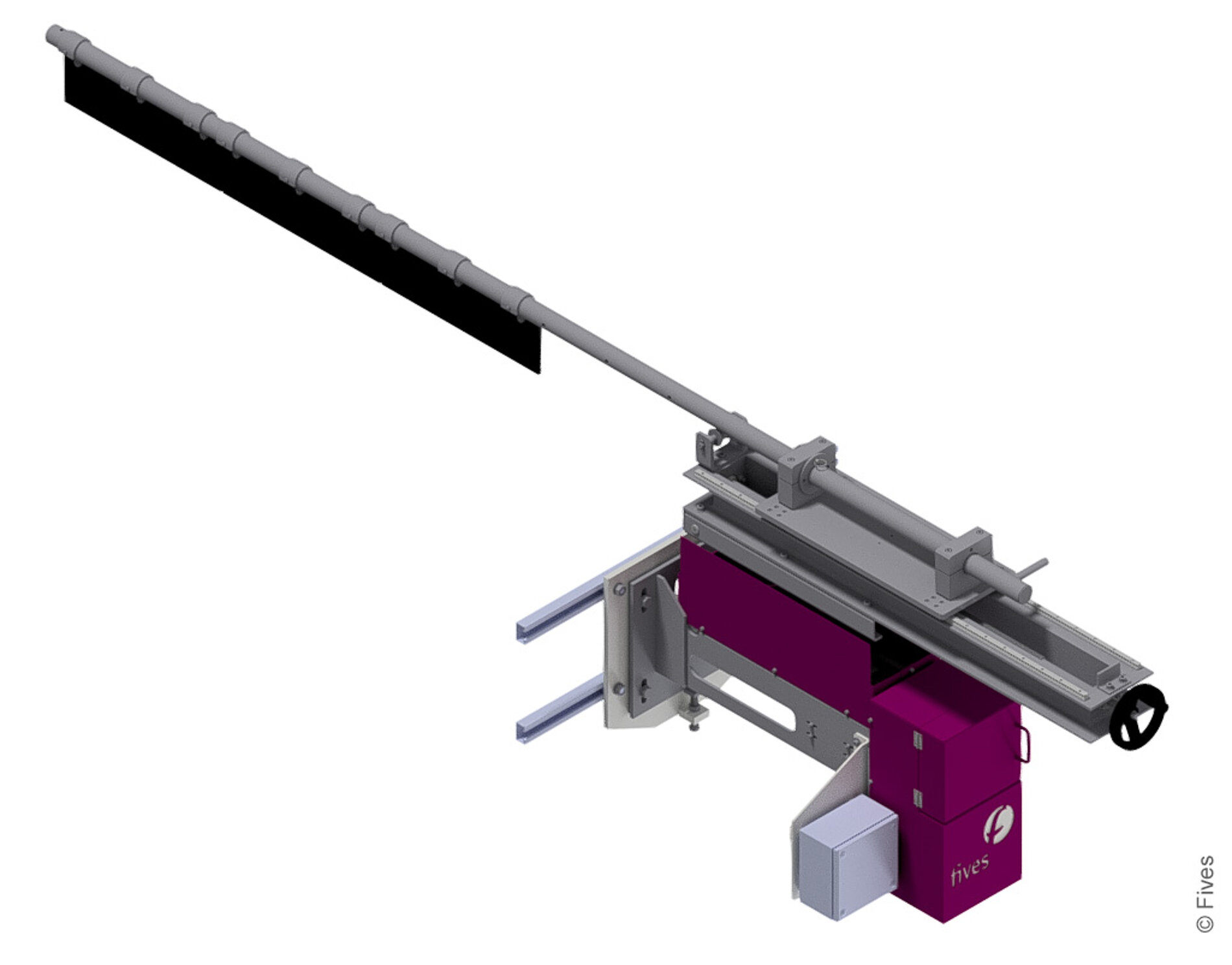

Flag system

The flag allows for the installation of barriers between the edge of the ribbon and the edge of the refractory to prevent return currents at the head of the bath. It is equipped with an emergency lifting system. Its width is easily adjustable based on the width of the ribbon being produced.