Oxy-fuel combustion increases furnace efficiency, reduces emissions and improves glass quality by creating a more stable process for the production of flat, container, and tableware glass. The addition of oxygen to the fuel almost eliminates nitrogen from the oxidiser, which greatly reduces the mass flow rate of flue gas leaving the furnace.

Discover our energy-efficient furnace, the first of its kind in technology and capacity, installed at Guardian Glass’ Bascharage plant in Luxembourg.

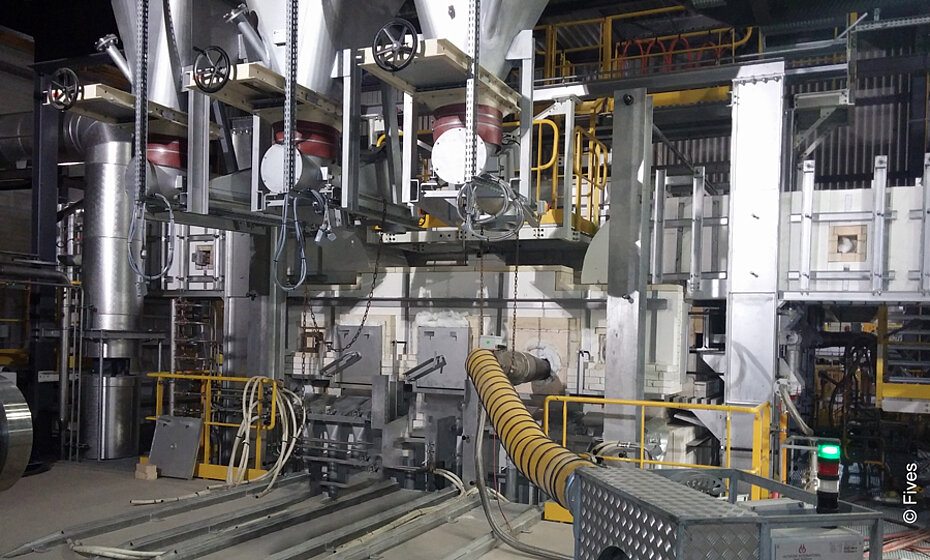

PRIUM® OXY-MELT

OPTIMIZED COMBUSTION

Fives has more than 30 years of experience in applying oxy-fuel combustion technologies to all types of glass melting furnaces, from greenfield projects to major rebuilds.

Prium® Oxy-Melt features an optimized design that allows for flexible oxy-fuel combustion compared to air-fuel tanks.

We integrate a vast range of oxygen and fuel injector solutions to suit each application and furnace size. The combustion space is designed to prevent hot spots, minimize the evaporation of volatile compounds, limit batch carry-over, and maximize heat-transfer efficiency.

Heat Recovery Area

MAXIMUM THERMAL EFFICIENCY

The Heat Recovery Area - H.R.A.™ - is a patented energy saving solution that reduces gas consumption by up to 10%. Its revolutionary design forces the flue gases to sweep smoothly above the batch blanket, providing several benefits:

- Optimized radiative heat transfer to the batch blanket

- Improved thermal efficiency

- Low flue gas temperature

- Reduced energy consumption

Fives’ proprietary H.R.A.TM technology was named Solar Impulse Efficient Solution.

PIONEERING TECHNOLOGY AT GUARDIAN GLASS

A low energy oxy-fuel furnace has been successfully installed in Guardian Glass’ most energy efficient furnace in Luxembourg to reduce heat loss and gas consumption without compromising glass quality.

Over time, the use of this technology should reduce the furnace’s gas consumption by 25% and CO2 emissions by 20% compared to a conventional air-fuel furnace.

“We trusted Fives to implement a new technology as they have extensive experience with electric and hybrid melting for various glass applications. The new furnace provides our Bascharage plant with additional capacity to produce both float and low-iron float glass at maximum pull.”

GUARDIAN GLASS