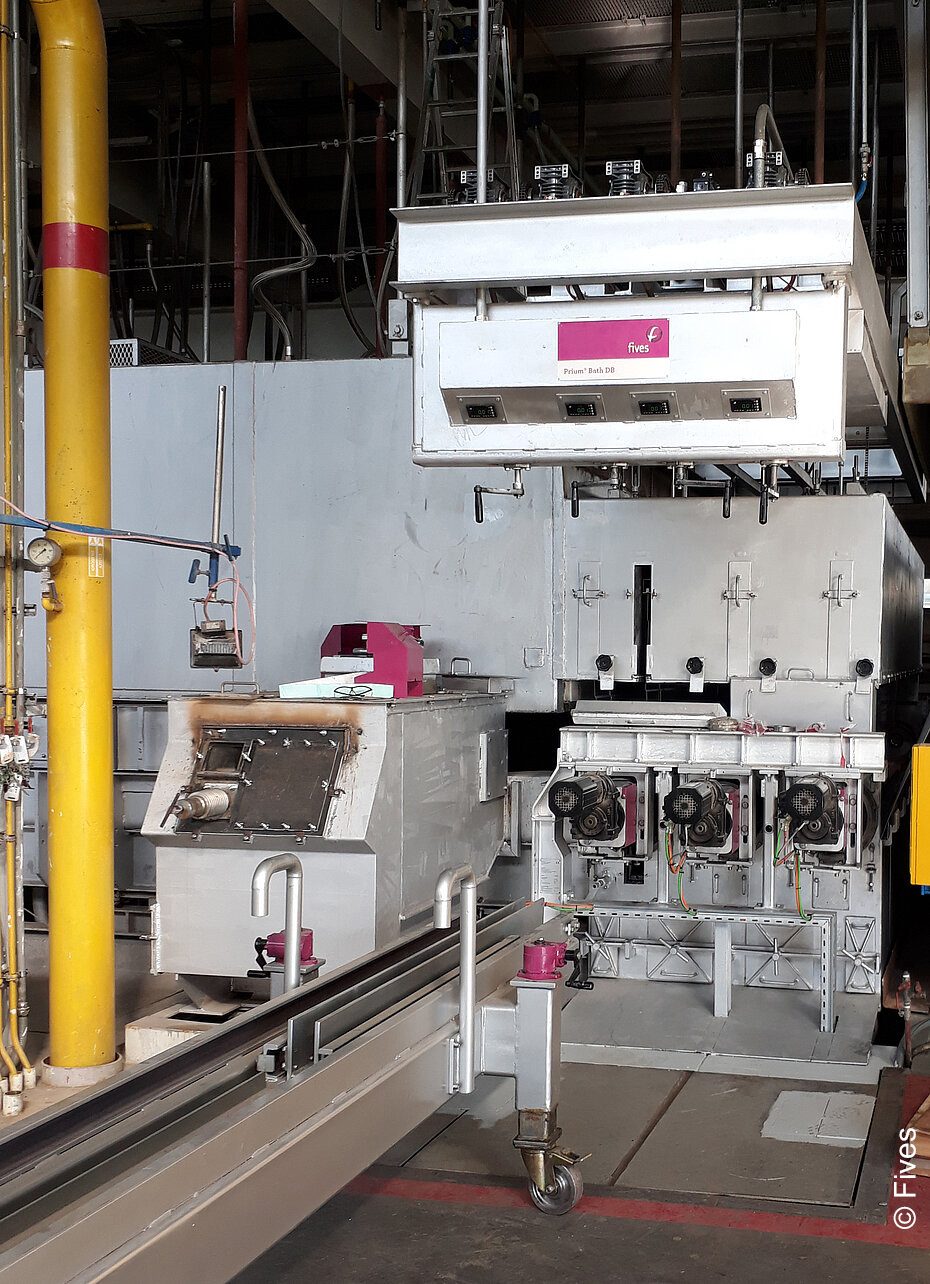

Our proprietary DrossBox technology, with over 60 installations worldwide, maintains good sealing, high rigidity, easy maintenance, and thin glass configuration.

DrossBox is essential for flawless glass ribbon transfer from the tin bath to the annealing lehr, offering:

- Controlled atmosphere: maintains a nitrogen-rich environment to keep air out

- Stable production: precise control of glass ribbon speed

- Easy handling: operation and maintenance are made easier thanks to the design.

⇥ BENEFITS

|

Lower casing

The lower part of the DrossBox is made with a rigid casing with LOR bearings mounted on a separate frame, which also include:

- Clamping solutions

- SO2 injection ramps

- Sealed inspection doors

- Carbon ramp

- Adjustable LOR houses

- Carbon manages by pneumatic lift system

- Location/hole for thermocouple and pressure tap inside the casing

Carbon pneumatic ramp The home-made design allows to maintain a uniform pressure on the roller.

|

Hood with curtains

The hood is a complex assembly of steelwork and isolating materials. Its set of curtains is equipped with an emergency lifting device.

- Curtain emergency lift with high temperature pneumatic cylinder

- Stainless steel curtains with fabric on the lateral sides for better insulation

- Handwheel for curtain control

- Digital poistioning indicator