Tin bath coolers are used to cool glass with radiation above the glass ribbon. Typically used in pairs, they use indirect cooling to control the glass ribbon temperature.

Optimized glass viscosity

The tin bath coolers, consisting of water-cooled rectangular tubes, adjust the viscosity of the glass ribbon for each production step. The cooling pipes can be equipped with an insulating sleeve for producing thin glass.

⇥ BENEFITS

|

Head coolers

The head coolers are suspended and installed on each side of the tin bath entrance. They overlap at the center to optimize the cooling in accordance with the glass thickness. Movement can be motorized or operated manually.

Head cooler at the tin bath entrance optimizes production conditions by maintaining ideal glass temperatures through heat radiation absorption above the ribbon.

End coolers

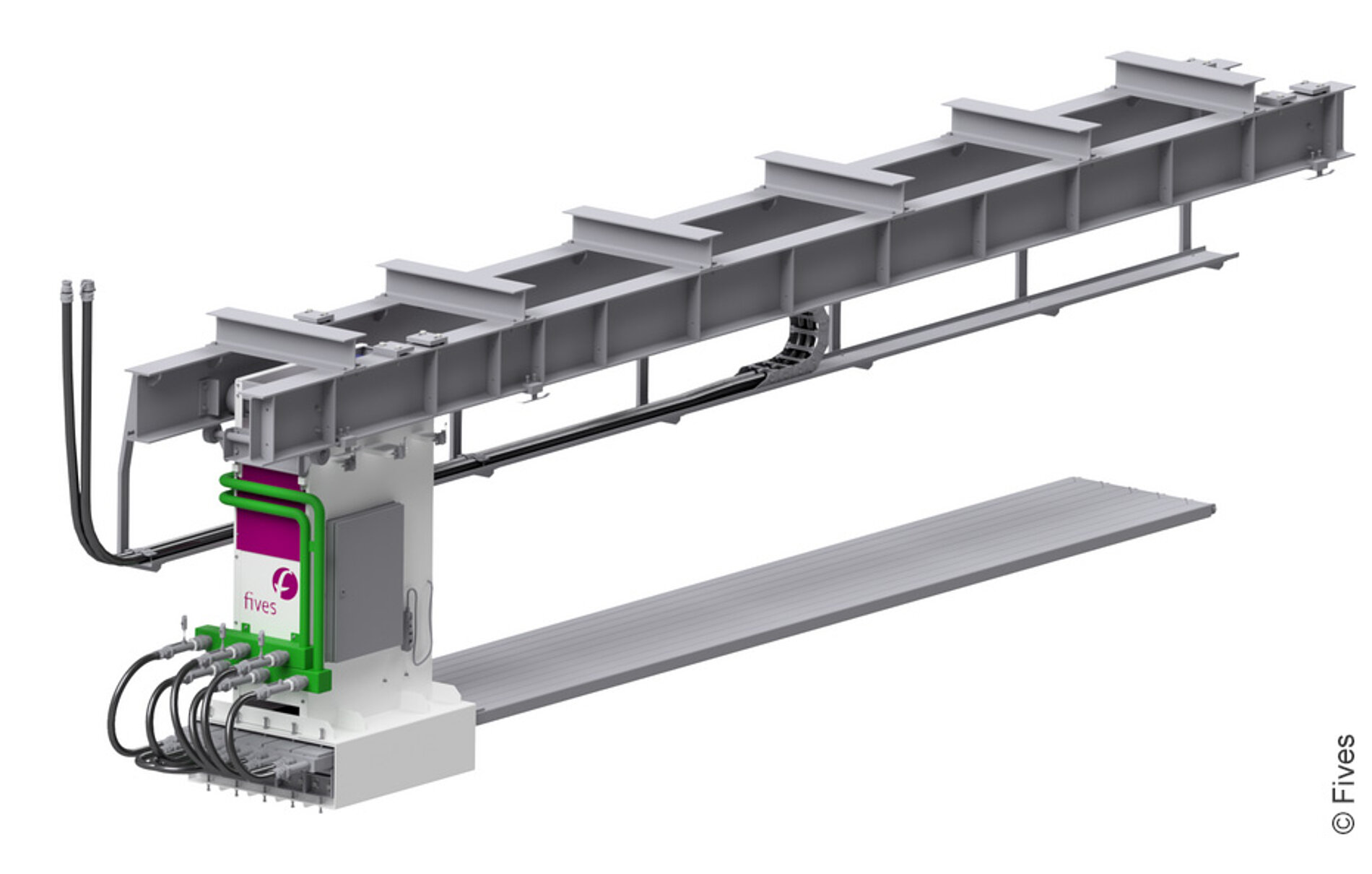

End coolers, installed at the bath's narrow end, condition the glass ribbon temperature before being extracted from the tin bath. Suspended in a steel structure with integrated cooling pipes, each cooler has independent water connections.

These motorized coolers increase the ribbon's viscosity without causing strong internal stresses.