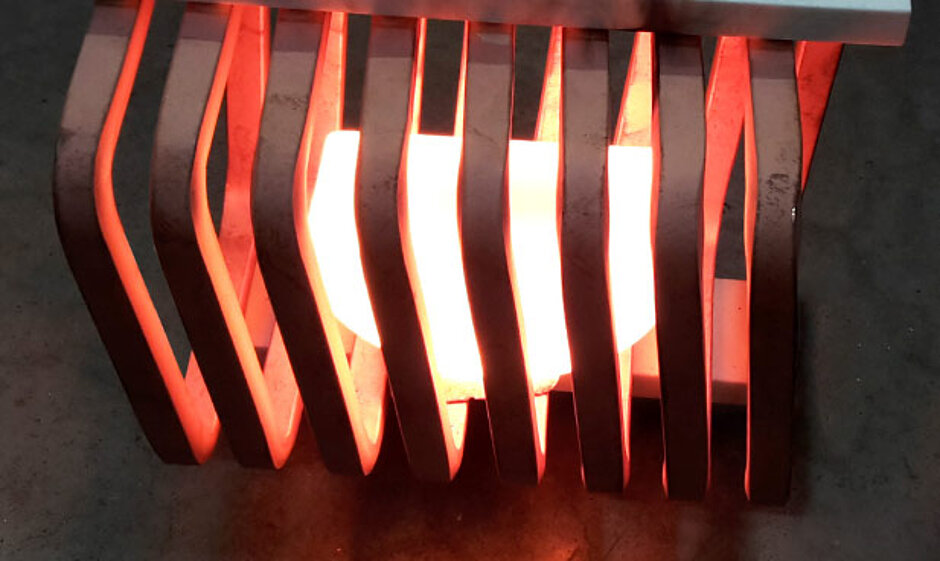

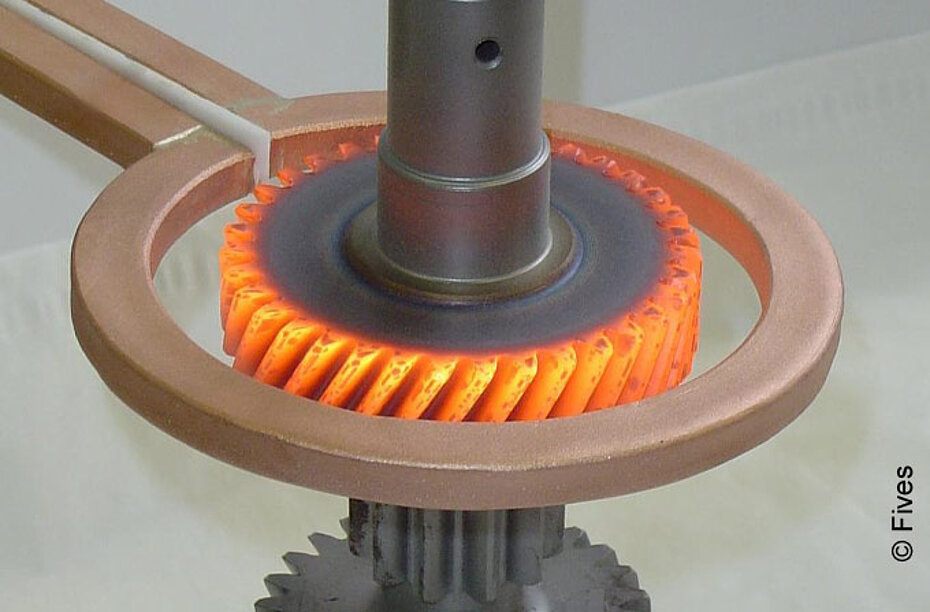

Induction annealing is a process for heating metals that are already highly processed and can add specific properties: it softens, improves ductility and reduces internal stress.

OPTIMIZATION OF METAL CHARACTERISTICS

The annealing process consists of heating the metal to a specific temperature and then cooling it at a slow and controlled rate. Ideal for steel, but also for copper, aluminum or brass.

Annealing is the best solution for:

- Softening cold worked metals

- Increasing electrical conductivity

- Restoring ductility and improving machinability

Our induction annealing solutions enable you to:

- Heat only the area to be treated

- Consume only the energy needed

- Easily integrate with a production line

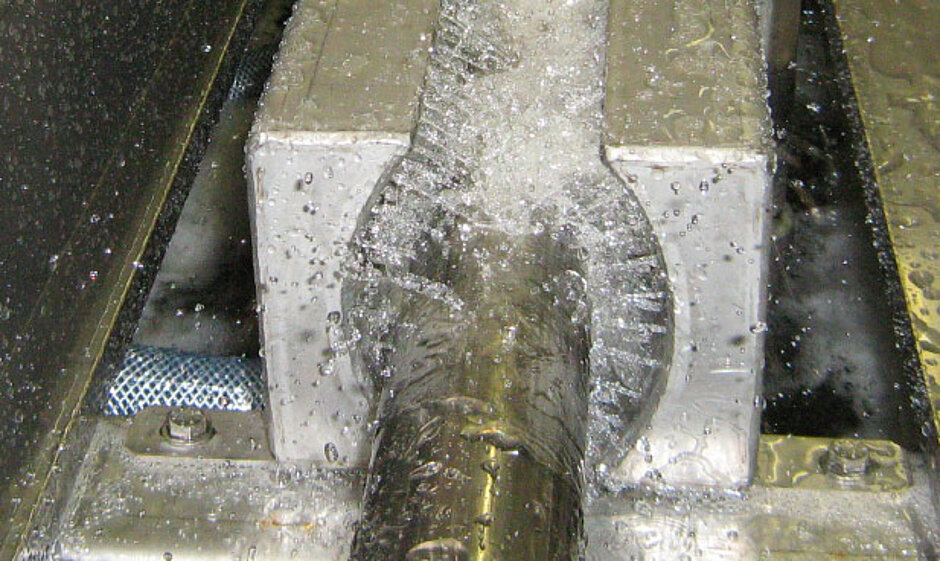

ANNEALING OF WELD SEAMS

Easy integration into an existing steel strip or tube production line

This solution allows induction annealing of the weld seam after assembly, limiting the risk of breakage:

- Fast heating of the weld seam

- Reduced heated area due to the magnetic circuit integrated in the inductor

- Reproducible heating sequence