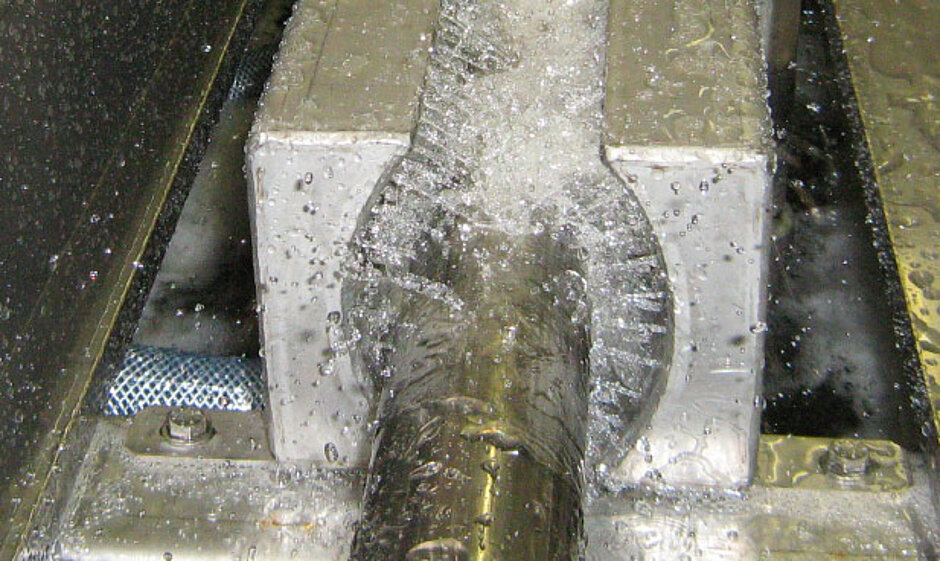

Offering superior efficiency, precision and strength, our induction welding equipment delivers consistently high-quality results with a smooth surface weld.

Induction welding for various applications

Induction welding is established as the most productive and efficient method for welding pipes, tubes and other closed profiles, including finned tubes for heat exchangers.

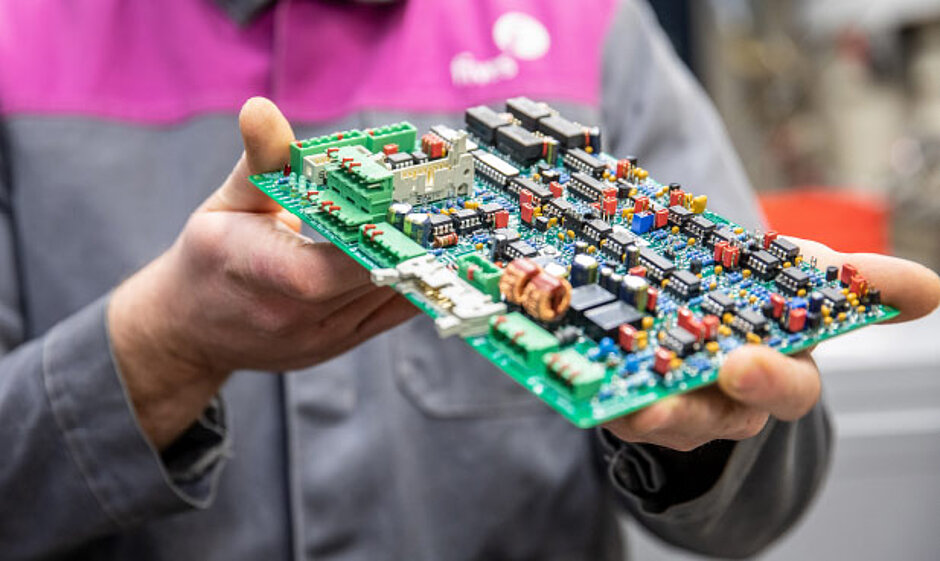

With 50 years' experience in induction technology, our engineers have the expertise and the knowhow to optimize your welding process. No matter how complex your application, we can engineer a solution that will improve the quality and efficiency of your welding and increase your productivity.

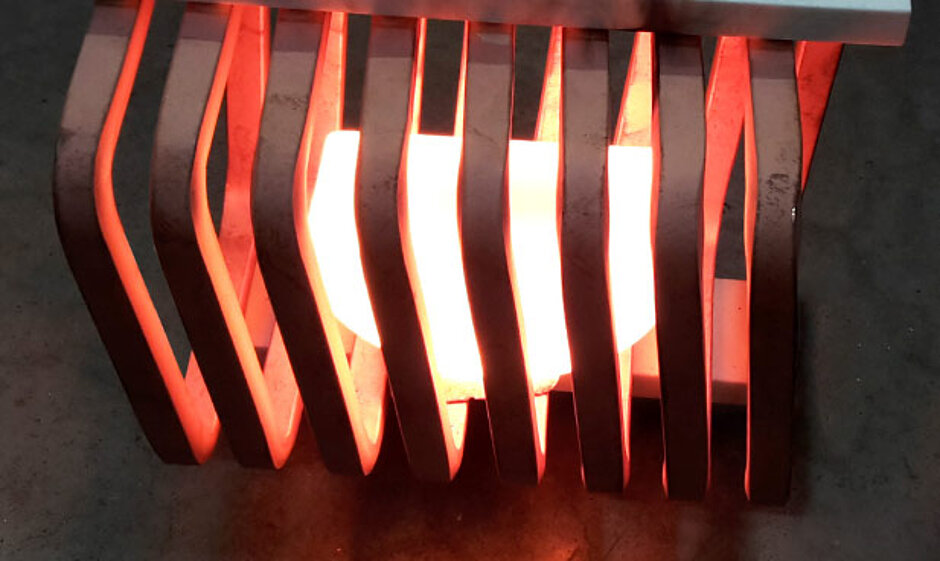

With induction technology, welding of large or irregularly shaped parts can be done quickly and cleanly.

High productivity

EVEN WITH DIFFICULT-TO-WELD MATERIALS

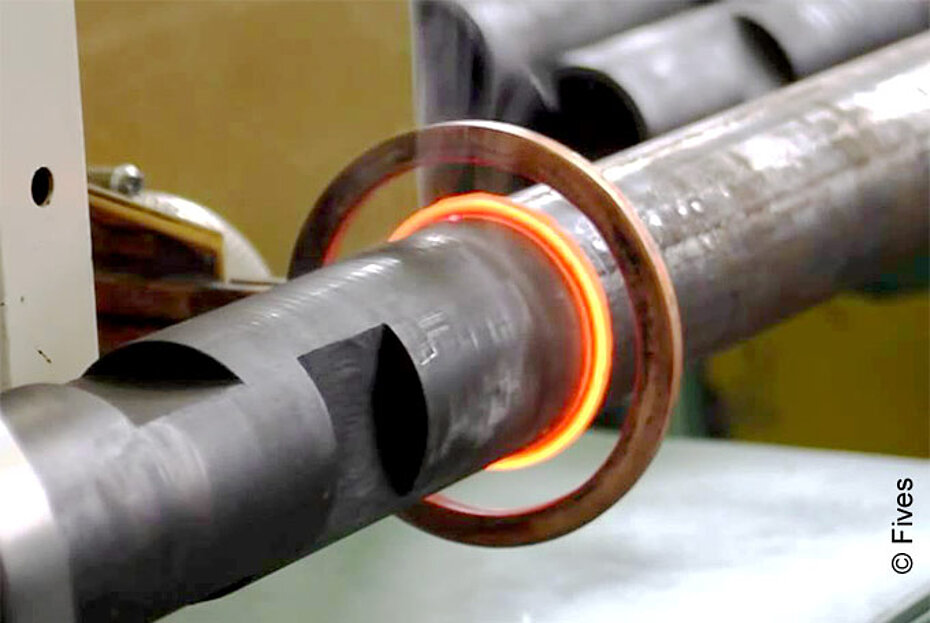

Sustainability goals are leading to greater use of new, lighter and stronger materials, such as copper.

Induction welding is ideal for these materials, offering numerous advantages over conventional welding techniques.

BENEFITS:

- High-quality welding with a uniform result

- Optimal performance and flexibility

- Precise heating area (minimizing heat-affected zones)

- Shorter heating zone (lower energy consumption)

- Low maintenance

- Easy integration into production lines

- Can be automated for high volume production