Our advanced Claus burner for sulfur recovery units

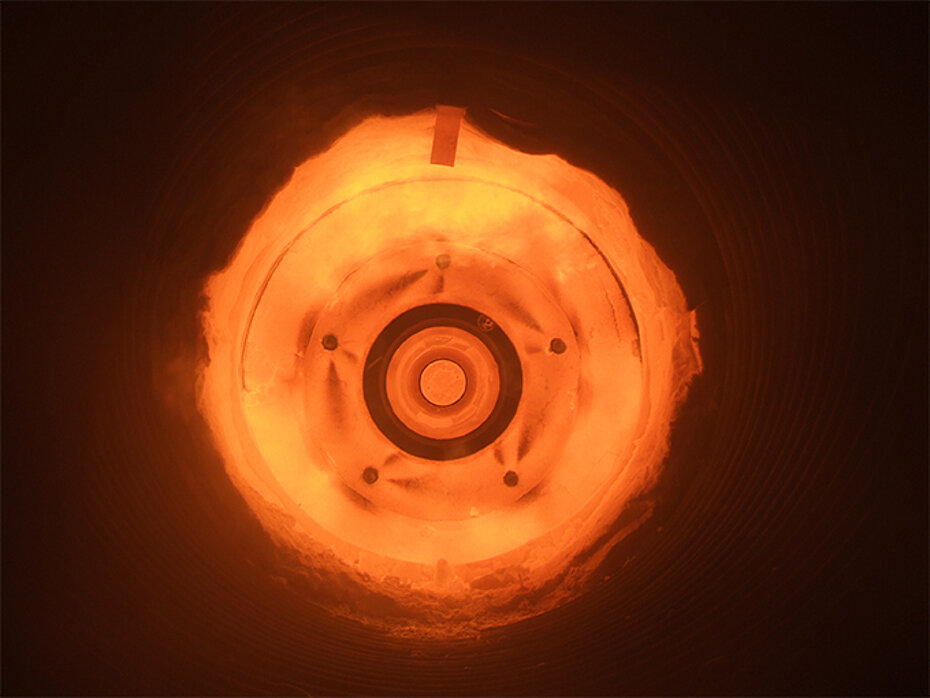

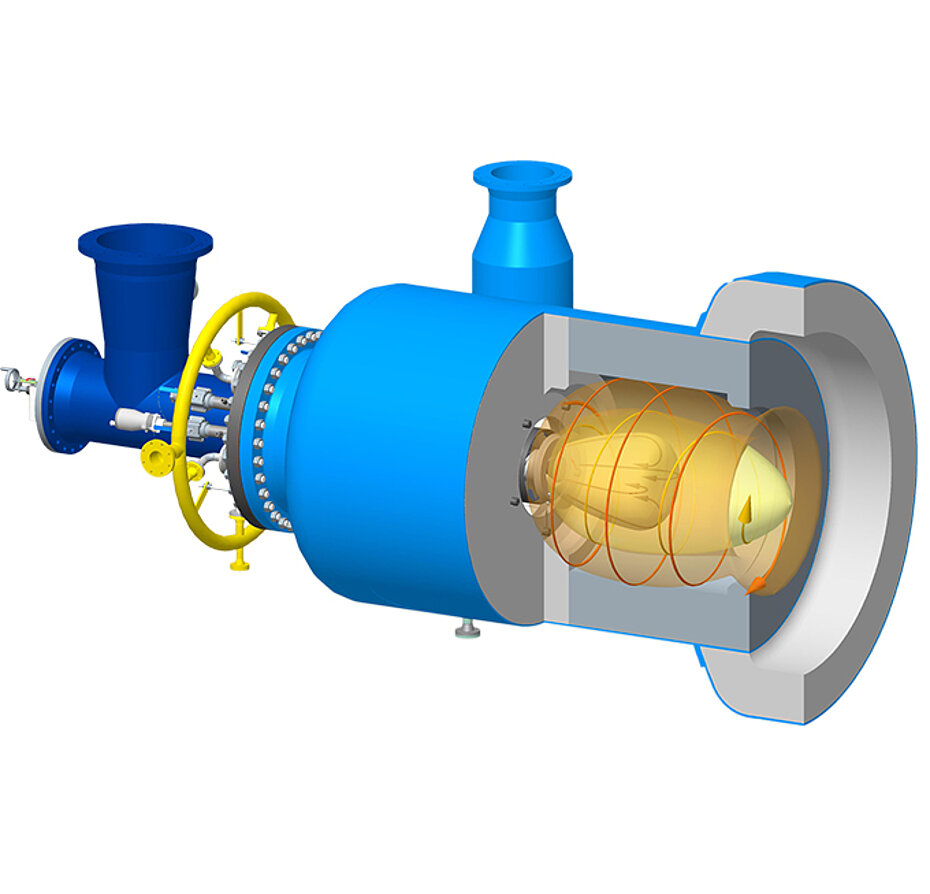

Fives’ Pillard SULFLAM® Claus burner is designed to mix combustion gases in the post-flame zone of a sulfur recovery unit (SRU), at high temperature. This is vital for an efficient Claus reaction within the furnace (2H2S + SO2 ->2 H2O + 3/2 S2).

A double-impulse, high-intensity burner

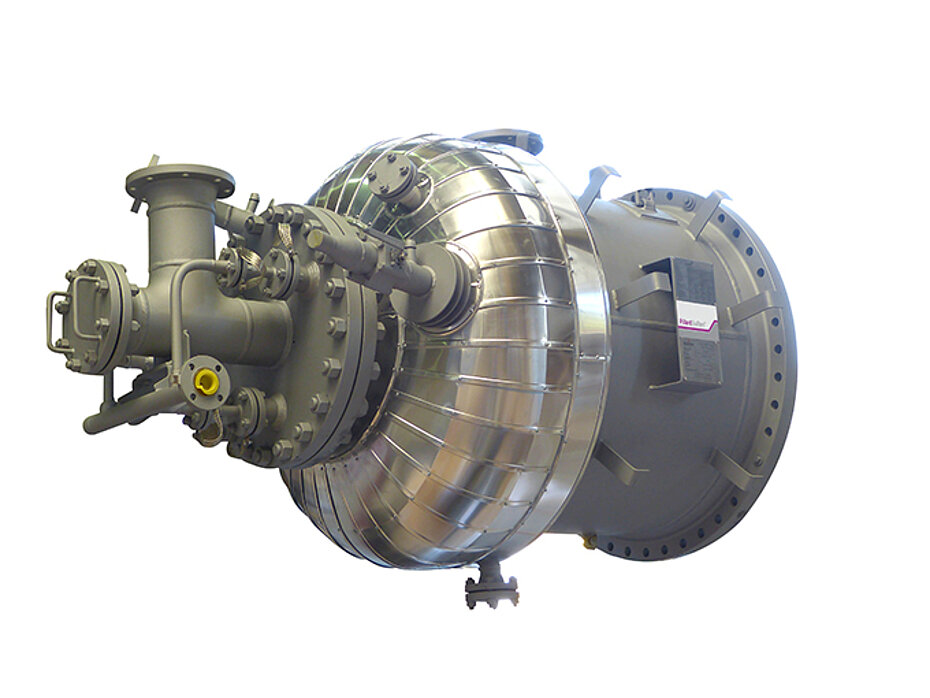

Each Pillard SULFLAM® burner is tailor-engineered through in-house computational fluid dynamics (CFD) modeling. This ensures optimal performance, according to each unique SRU’s process characteristics. The burner is available in axial and tangential firing configurations, adaptable to any kind of combustion chamber.

Pillard SULFLAM® ensures excellent flame stability in high excess air conditions during cold start-up and refractory dry-out phases. It is designed with a double stream acid gas tip to enable a two-stage mix and a double impulse, matching the different phases of the kinetic reaction in the Claus furnace.

Key benefits:

• High-intensity, compact flames

• Excellent mixing

• High flame stability, even with a lean acid gas stream and during the cold start-up and refractory dry-out phases, under high excess air conditions

• High turndown ratio with low acid gas pressure

• Efficient processing with very lean acid gas, using conventional Claus and associated tail gas units

Specific fuel gas co-firing design

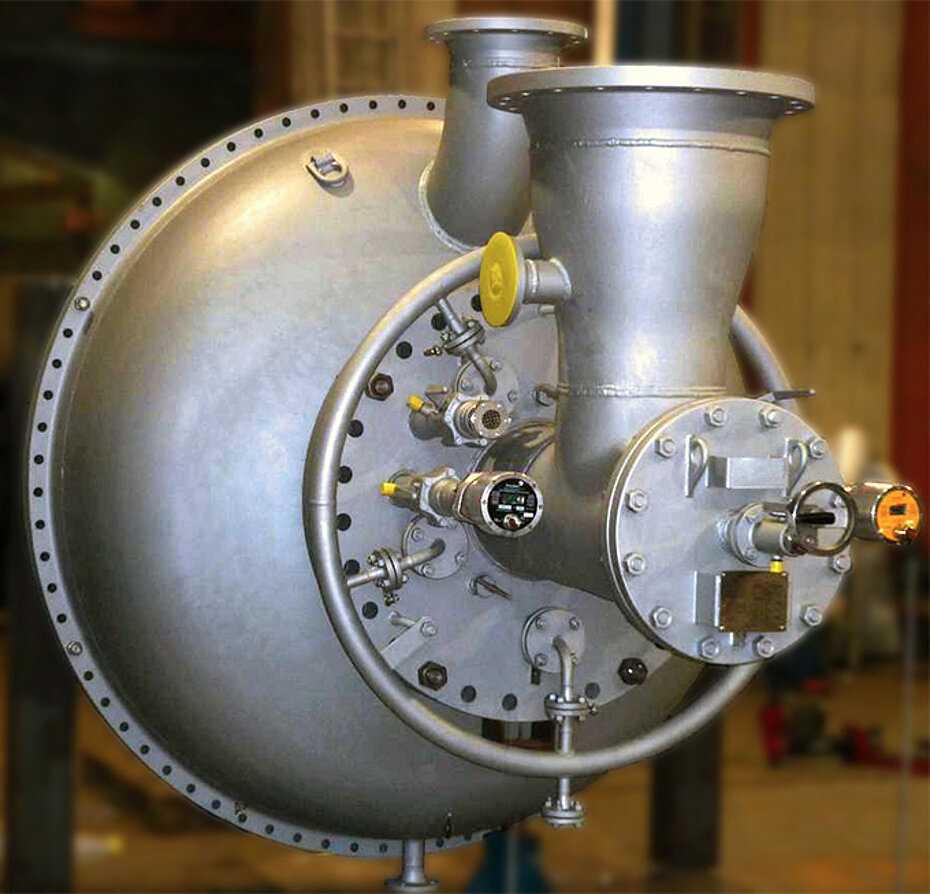

The Pillard SULFLAM® burner has a very specific design for co-firing fuel gas. This is essential for increasing the flame temperature when operating with hydrogen sulfide (H2S) lean acid gas. The fuel gas is added peripherally and injected into the combustion air, where it is burned with the required amount of excess air. The remaining air can then be used in the Claus reaction.

This configuration efficiently burns off fuel gas, reducing the risk of unburnt hydrocarbons, soot formation, and increased carbon disulfide (CS2) and carbonyl sulfide (COS).

When combined with a properly engineered thermal reactor furnace, the Pillard SULFLAM® burner offers:

• High sulfur quality

• Increased disulfur (S2) conversion efficiency

• Reduced downstream pollutant levels (e.g. BTX)

• Better catalyst lifetime when using a co-firing technique

• An improved refractory lifetime

A flexible solution for new plants and retrofits

Pillard SULFLAM® is available in axial and tangential firing configurations. The burner can easily be retrofitted in existing SRUs to improve S2 conversion efficiency, sulfur quality and the refractory lifetime of the Claus unit.

It is available for a range of Claus units, from 5 to 1,000 TPD.

Past clients include:

ADGAS (UAE): 500 TPD

-

Retrofit of an existing burner, including refractory supply

-

Using very lean acid gas (26.5% H2S)

-

Excellent sulfur quality

Total Lacq (France): 600 TPD

-

Almost 100% BTX destruction using a staged co-firing technique

-

No soot formation

-

Excellent sulfur quality

-

Five years’ continuous operation without incidents

Lukoil (Russia): 10.5 TPD

-

Presence of unsaturated hydrocarbons in the feedstock

-

Using very lean acid gas (28% H2S) without requiring oxygen enrichment or acid gas enrichment

-

BTX destruction using a staged co-firing technique with minimum fuel gas flow, by preheating the fuel and acid gases

-

Cold climate: -35°C (-31°F)

-

Bright yellow sulfur, with no signs of carbon contamination