Simplicity, reliability, high efficiency and ease of operation

Fives supplies high efficiency pelletizing burner systems to the iron ore industry. We continue to offer the most efficient and reliable systems for burning fuels, from the heaviest residual oil to low Btu gases. All our industrial burners are designed for cold fired start and flame supervision with all fuels.

More than 90 North American pelletizing systems have been installed in 15 countries worldwide, across 6 continents.

The North American Pelletizing burner combined with a North American Safety programmable logic controller (PLC) shortens start up time and provides real-time annunciation of problems.

North American 4235 EcoFornax™ LE ultra-low NOx pelletizing burner

Iron pellet producers around the world are continuing to pursue cleaner and more efficient production processes. The expectation is that all pellet producers will adopt combustion technologies that will significantly improve energy consumption, lower furnace emissions and sustain operational flexibility.

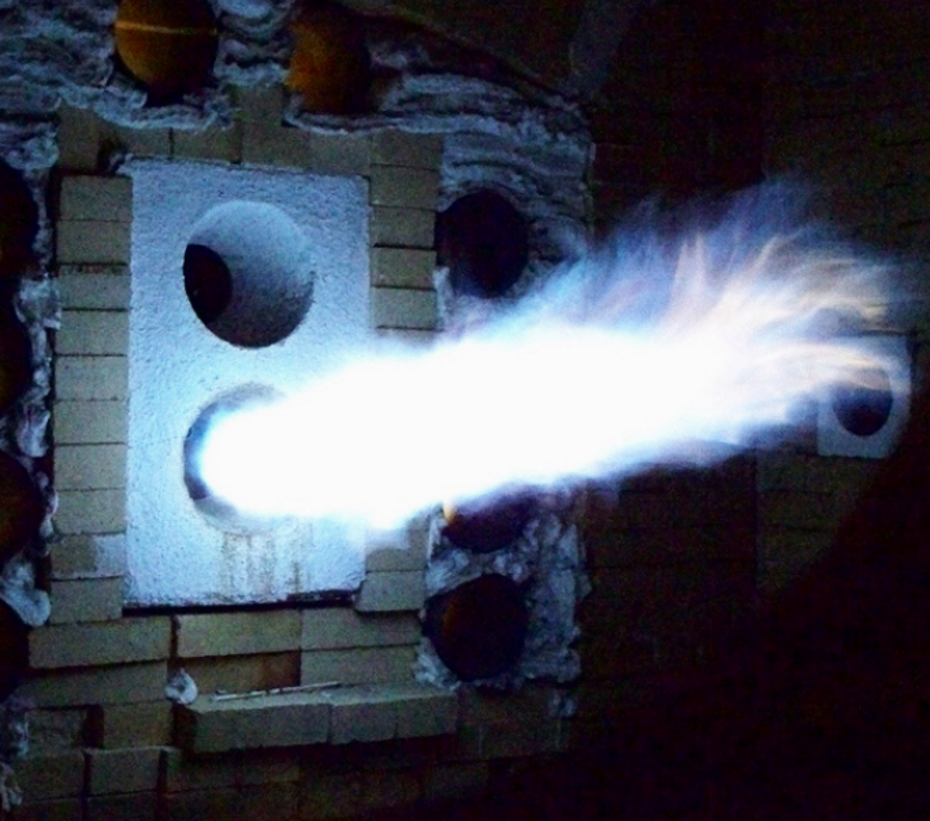

North American pelletizing burners provide cutting-edge NOx reductions and efficiency for iron ore pelletizing systems. The North American 4235 EcoFornax™LE has lower capital and operating costs than after-treatment while increasing product uniformity, quality, and refractory life through its lowered peak flame temperature and compact flame envelope. Above all, this industrial burner champions an unmatched NOx emissions reduction potential of up to 95%.

The North American 4235 EcoFornax™ LE technology has been developed with the aid of computational fluid dynamics (CFD). This work has resulted in the technology being recognized as best available retro-fit technology (BART) in a 2013 US EPA Federal Implementation Plan. It is recognized for the elimination of regional haze and the return to pristine conditions for the federal lands in the states of Minnesota and Michigan.

North American 8984 Safety PLCs for the pelletizing industry

A North American Safety PLC-based control system is superior to a relay and timer-based system. The PLC platform provides better diagnostics and troubleshooting, and significantly reduces panel wiring and interconnections. The system components are comprised of listed and/or approved safety instruments, approved safety shutoff devices, Safety Integrity Level (SIL)-2 capable PLC and a SIL-2 capable self-checking flame sensor. The burner management system (BMS) is designed in compliance with each of our customers’ local codes.

A North American Safety PLC greatly facilitates remote diagnostics and monitoring capabilities. This enables our service technicians to work on a real-time basis with your operators to diagnose, troubleshoot and reduce potential system downtime. It also collects data which can be used to determine asset availability.